Water knife cutting control system

A control system and water jet cutting technology, applied in the direction of automatic control devices, manufacturing tools, metal processing machinery parts, etc., can solve the problems of unavailability, waste, high acceleration and deceleration, etc., to increase yield, improve accuracy, The effect of high acceleration and deceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

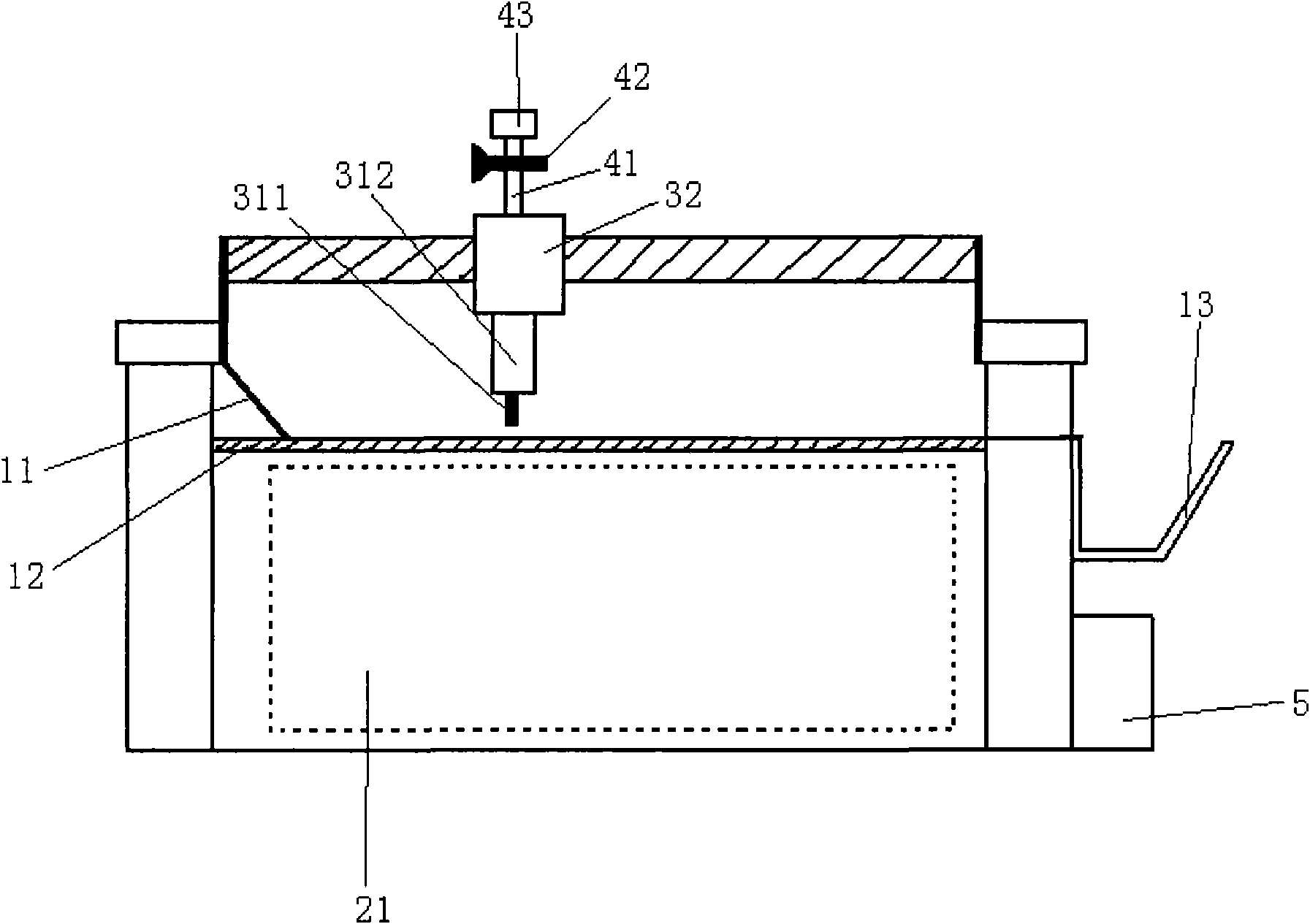

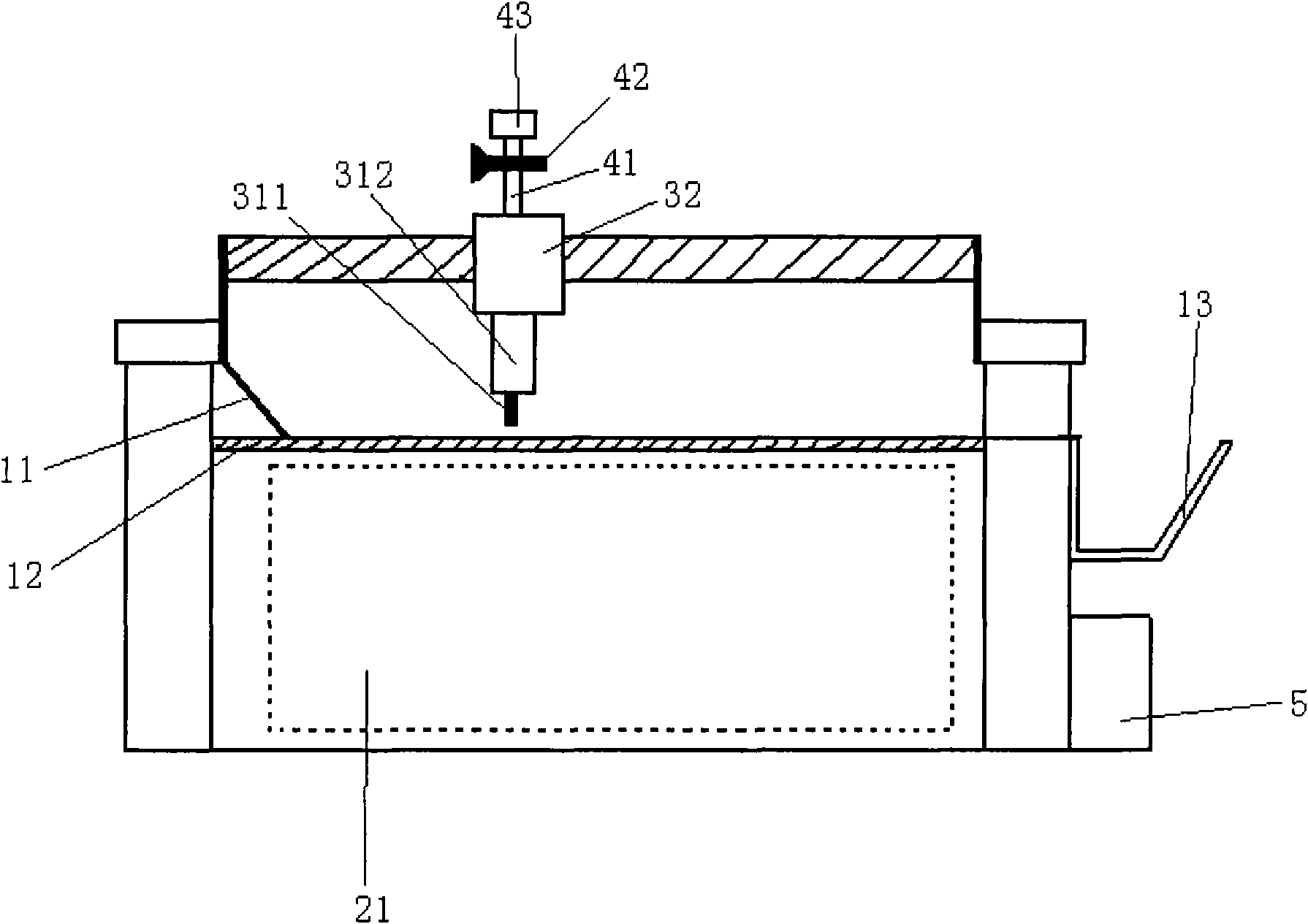

[0017] Such as figure 1 As shown, the water jet cutting control system is installed on the gantry, the system includes a feed system 1, a recovery system 2, a water jet movement control system 3, a water flow control system 4 and a workstation 5, and the feed system includes a feed port 11, Conveyor belt 12 and material receiving box 13, feed inlet 11 is above the starting end of conveyor belt 12 running direction, material receiving box 13 is below the terminal end of conveyor belt 12 running direction, and recovery tank 21 is located at the below of described feeding system 1, The width of recovery groove 21 is 1.5 times of conveyor belt 12 widths. The water jet movement control system 3 includes a nozzle 311 , a water pipe 312 and a movement control device 32 , the nozzle 311 is connected to the water pipe 312 , and the water pipe 312 is connected to the movement control device 32 . The high-pressure water flow control system 4 includes a high-pressure pipe 41, a jet valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com