Method and device for trapping ink

An ink, ink transfer technology, applied in printing, rotary printing presses, printing presses, etc., can solve problems such as large size, ink splashing, and inability to obtain normal operation status.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, one embodiment of the present invention will be described in detail with reference to the drawings.

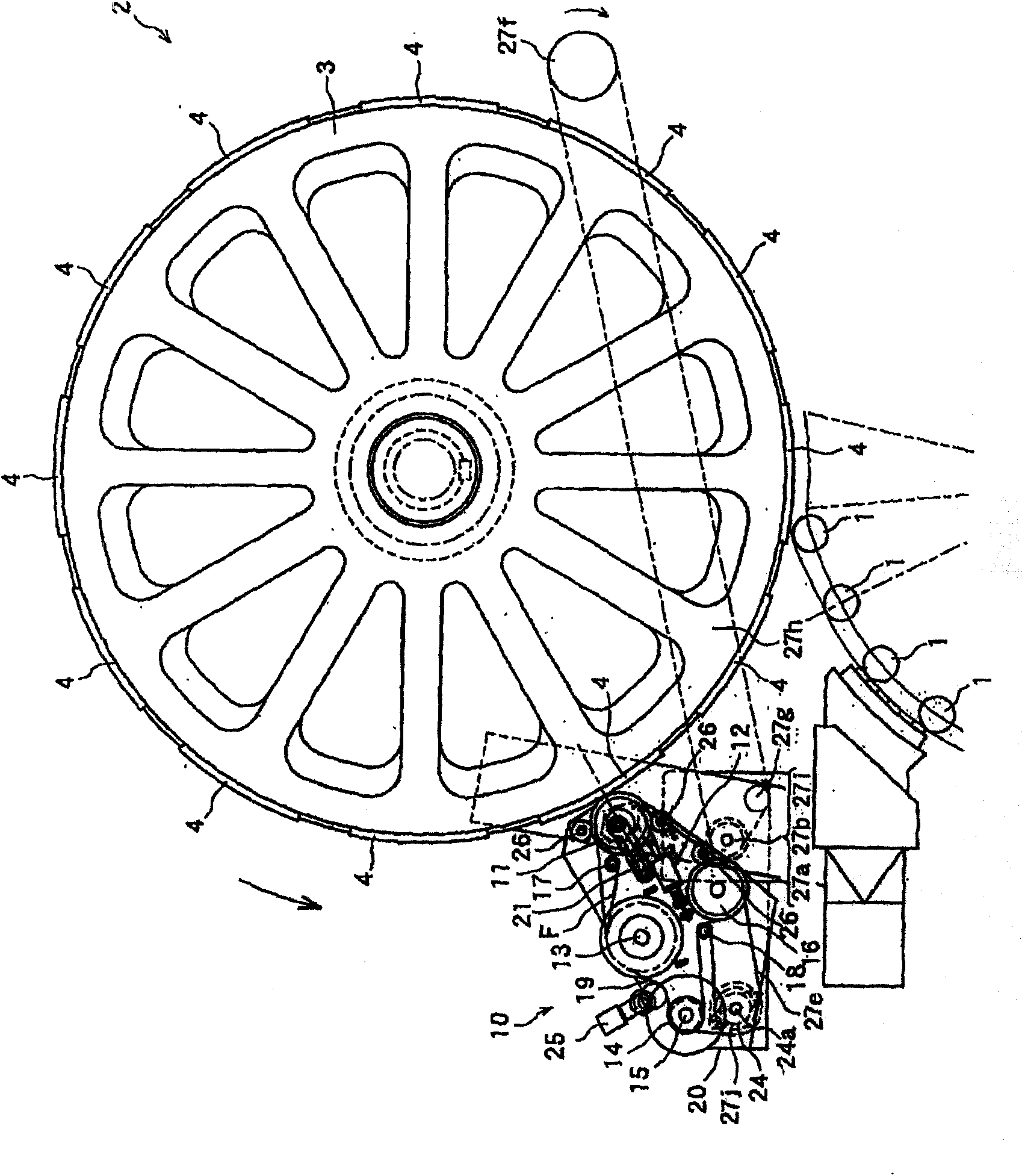

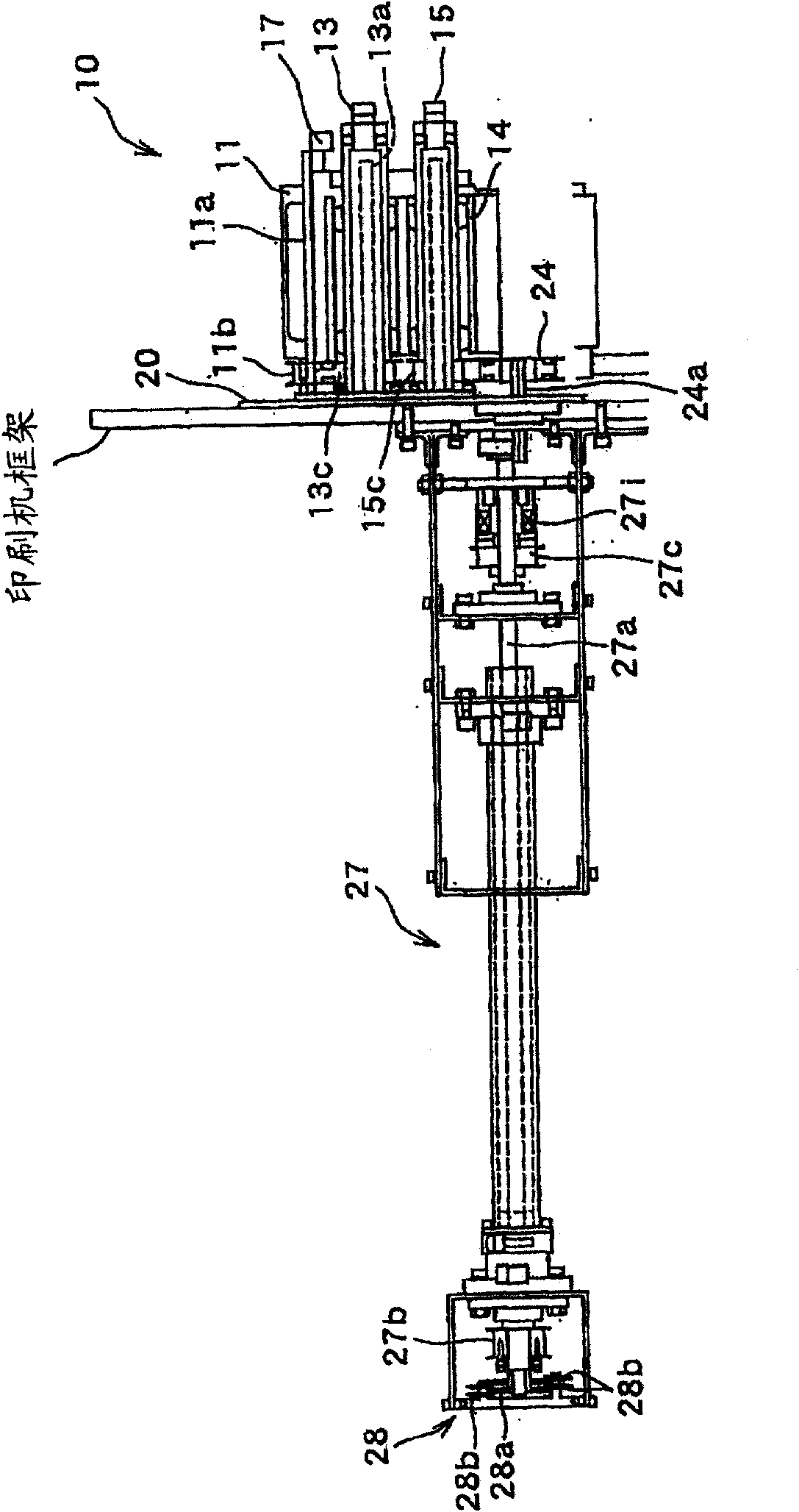

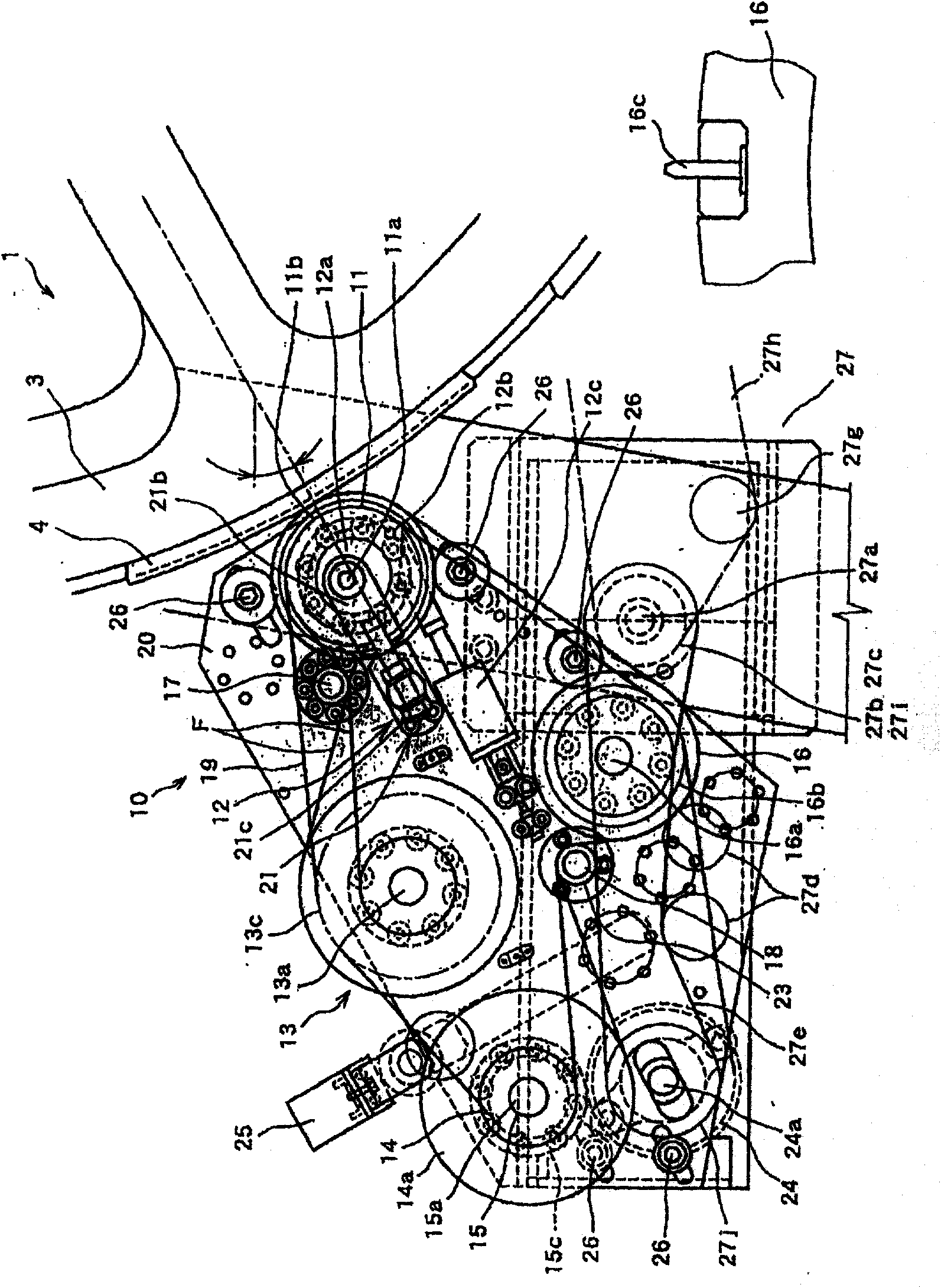

[0040] Figure 1 to Figure 6 An embodiment related to applying the ink trapping device of the present invention to a printing machine for printing can bodies, figure 1 is a schematic front view of the device as a whole, figure 2 is a schematic plan view of the entire device, image 3 is the enlarged main view, Figure 4 It is a cross-sectional view showing each roll developed, Figure 5 is an explanatory diagram of the catch roller contact retraction mechanism, Figure 6 It is an explanatory diagram of the position detection mechanism of the blanket.

[0041] The ink trapping device 10 is attached to the printing machine 2 that performs transfer printing on the can body 1, and is a device for removing excess ink or oozing ink before a normal printing state.

[0042] In a normal printing state, the printing machine 2 transfers ink to a plurality of bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com