Squeeze mop

A squeezing and mopping technology, used in carpet cleaning, floor cleaning, cleaning equipment, etc., can solve problems such as poor cleaning results and unfavorable use characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

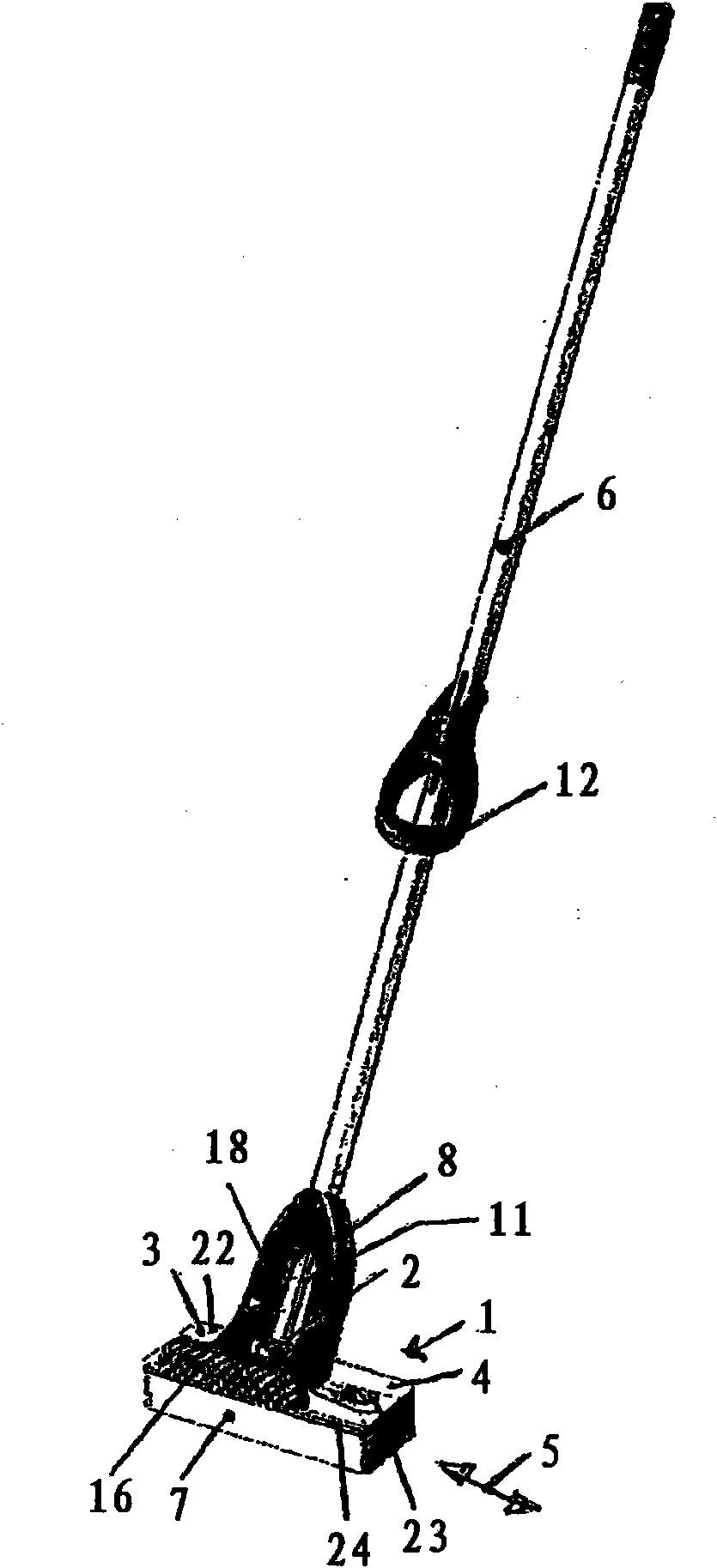

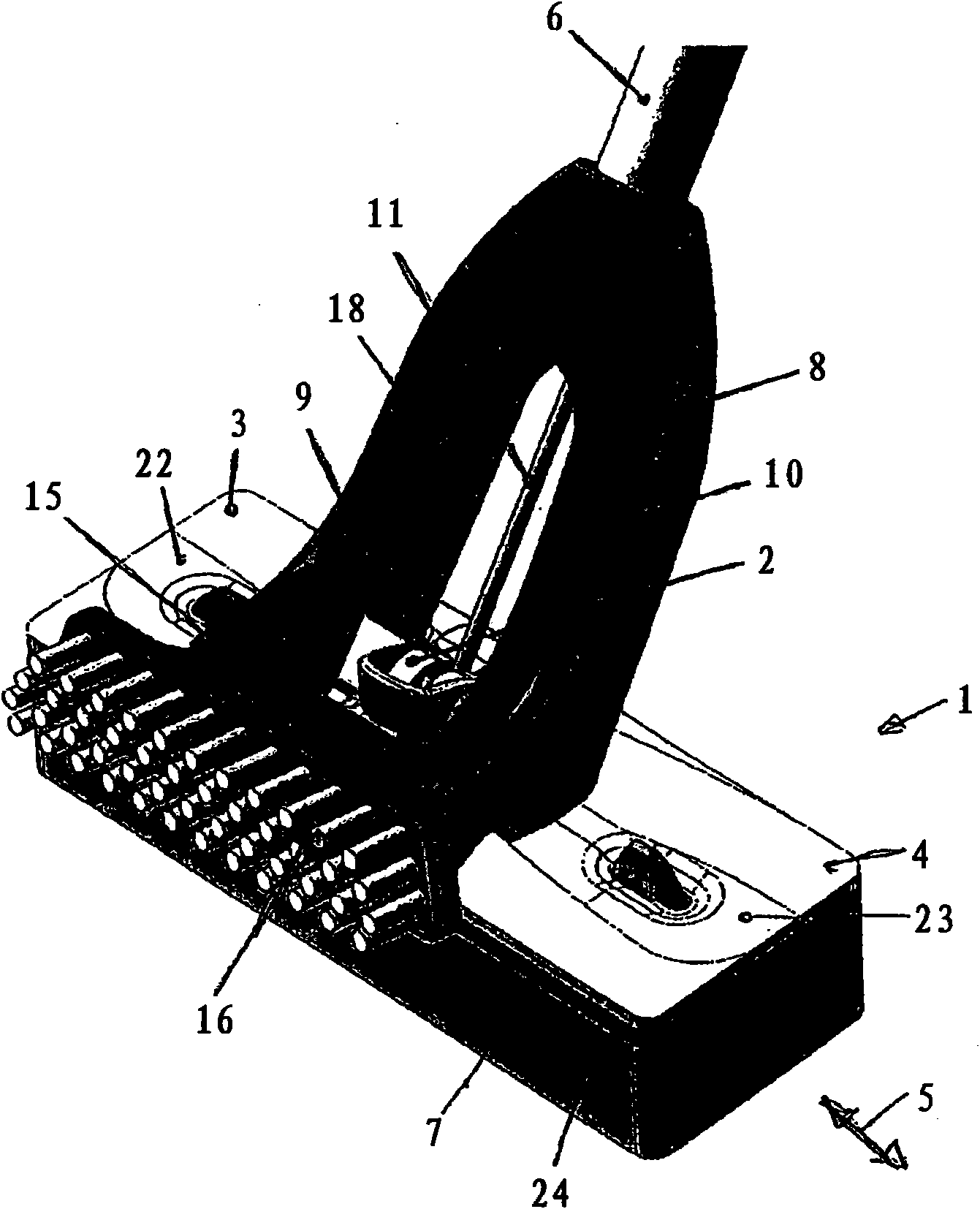

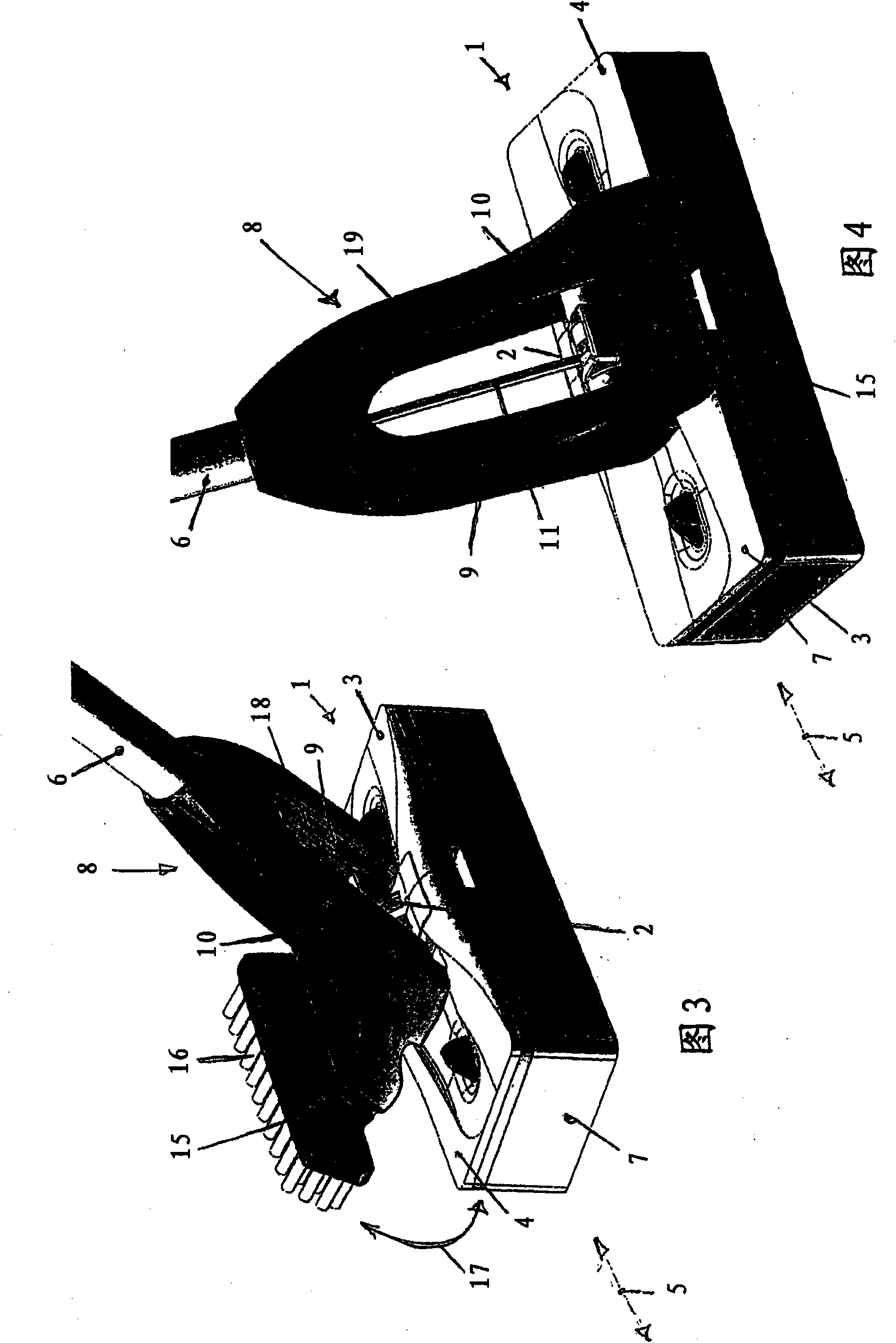

[0030] exist figure 1 and in Figure 2 to Figure 13 An exemplary embodiment of a squeeze mop according to the present invention is shown in . The squeeze mop comprises a carrier body 1 made of a polymer material and comprising a centrally arranged double joint 2, wherein in the longitudinal direction 5 of the carrier body 1 Corresponding wings 3 , 4 follow on both sides. The double joint 2 and the two wings 3 , 4 are connected to each other such that when the squeezing device 8 is actuated, the two wings 3 , 4 can each be swung downwards relative to the double joint 2 . On the side facing away from the handle 6 in the axial direction, the carrier body 1 has a single-part mop pad 7 which corresponds to the dimensions of the carrier body 1 and is designed in the form of a sponge. Instead of the single-part mop pad 7 described here, it is possible to use a multi-part mop pad, such as a two-part mop pad, in which case each part has the same dimensions as, for example, a wing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com