Prismatic cell

A battery, square technology, applied in nickel batteries, alkaline batteries, secondary batteries, etc., can solve the problems of obvious battery temperature rise, limited welding area of components, and small internal space of batteries, etc., to widen the current transmission channel, battery safety Performance improvement, avoiding the effect of battery safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

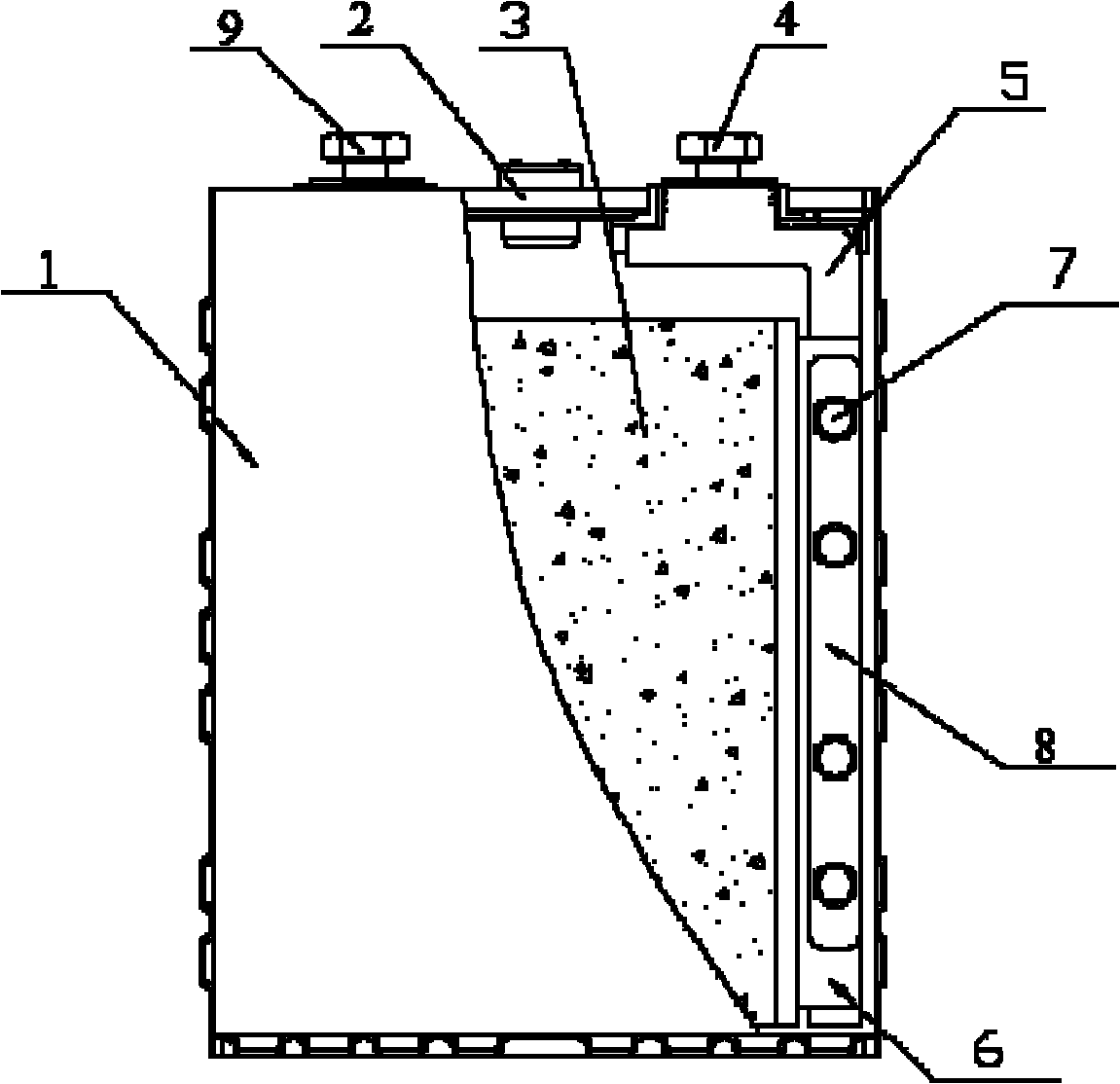

[0015] The square accumulator of the present invention, its longitudinal anatomical structure such as figure 1 As shown, it includes a rectangular casing 1, a sealing cover 2, a battery cell 3 built in the casing, a positive pole 4, a positive current collector 5, a negative pole 9 and a negative current collector. The battery cell 3 is composed of positive plates, diaphragms, and negative plates alternately stacked with each other. Holes are punched at the same positions of the white edge mesh parts 6 on one side of all positive plates, and the positive collectors are punched at the corresponding positions. Rivets 7 Connect the corresponding holes with the gasket 8, so that the positive plate is fixed on the positive current collector; the structure on one side of the negative electrode is the same as that of the positive electrode, that is, punch holes at the same position of the white edge mesh part on one side of the negative plate, and the negative plate is white The side...

Embodiment 2

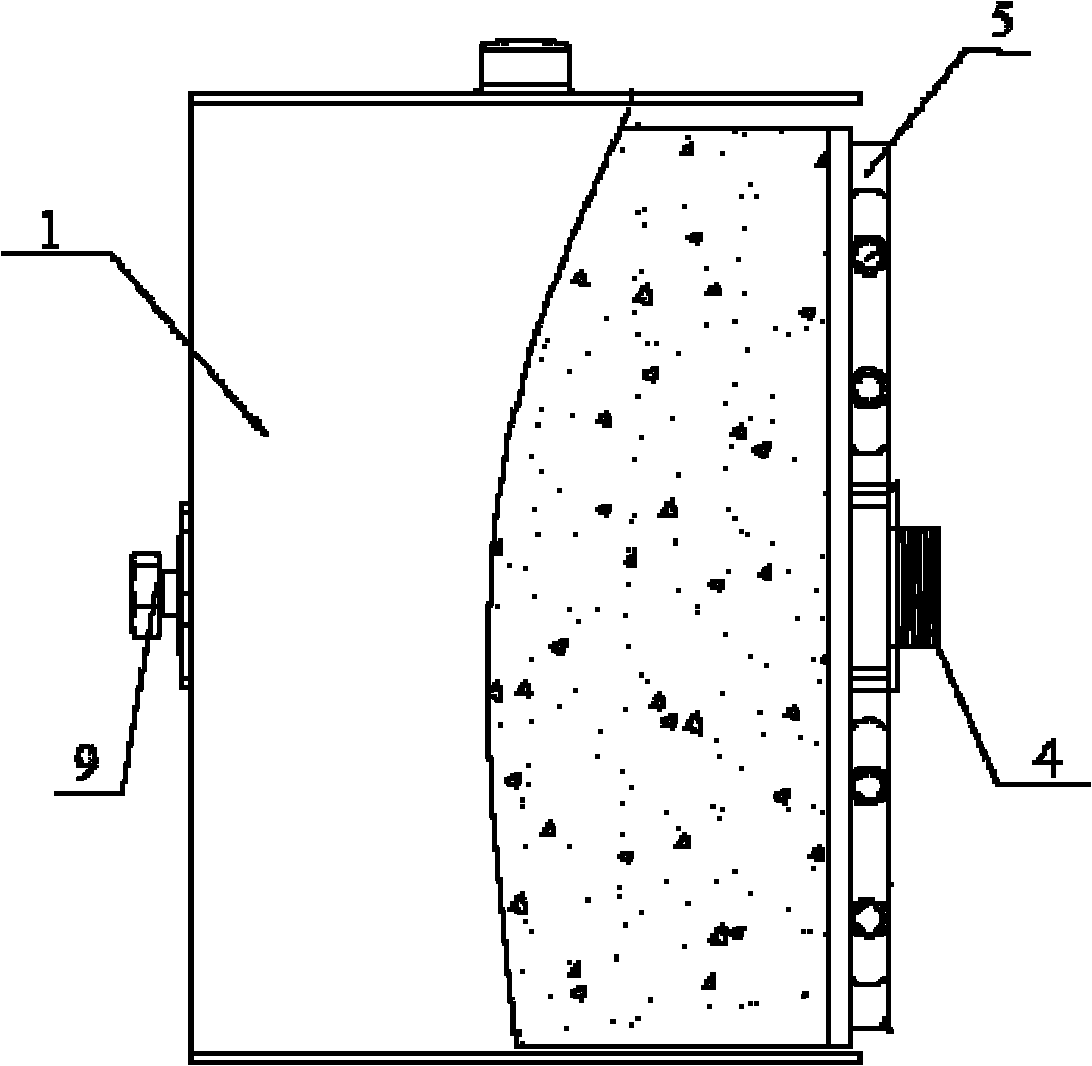

[0018] The schematic view of the longitudinal anatomical structure of the square accumulator of the present invention is as figure 2 As shown, the positive column 4 and the positive collector 5 are a Shaped overall module, the short side shows the pole, and the long side shows the collector; the negative pole and the negative collector correspond to a The short side shows the pole, and the long side shows the collector; the positive pole 4 and the negative pole 9 are both exposed outside the shell 1 and are sealed with the shell 1. All the other structures are the same as in Example 1.

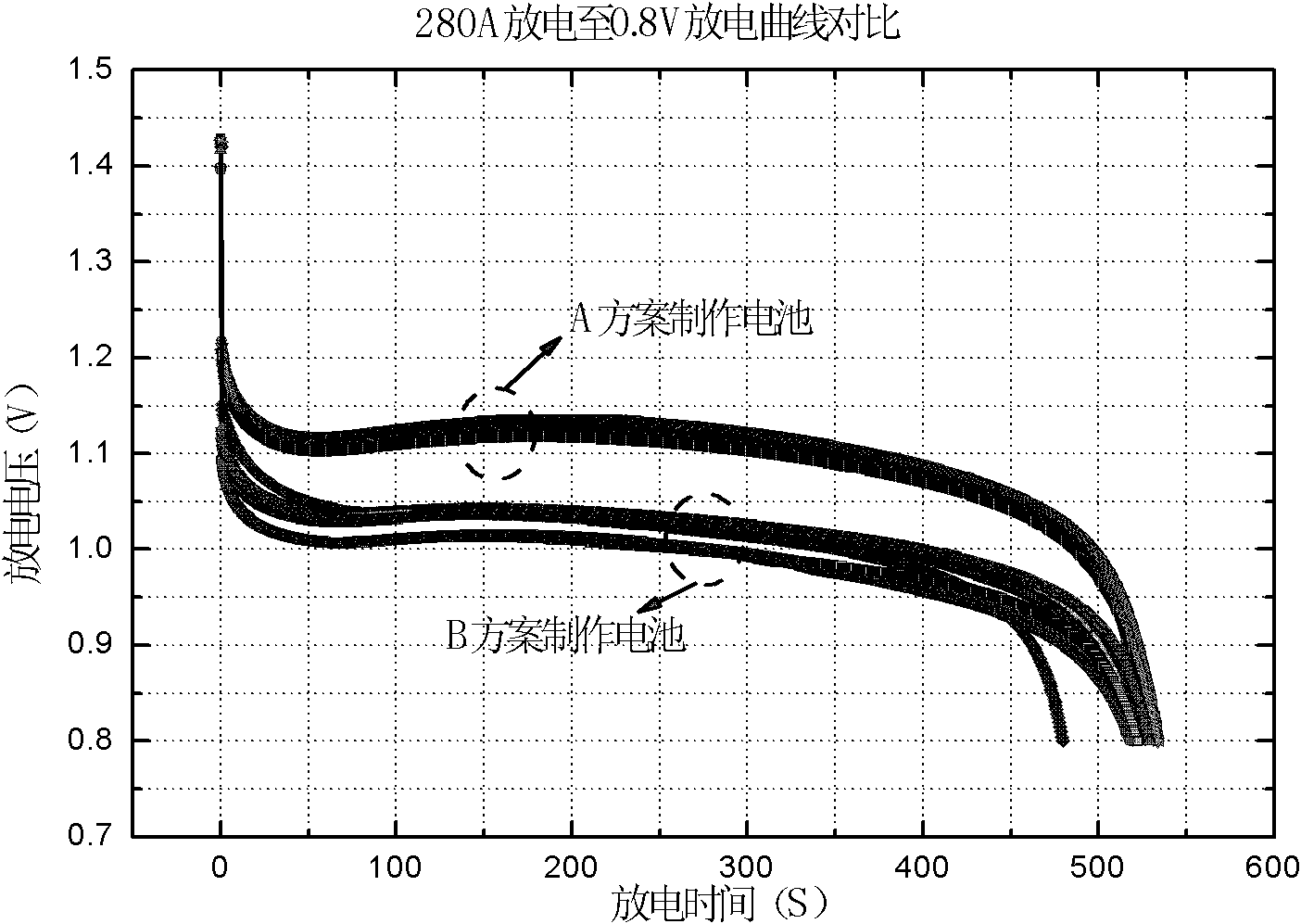

[0019] The method of this embodiment and the existing method were used to manufacture square metal hydride nickel storage batteries, respectively, and their vibration resistance performance was tested under the same test conditions. A square storage battery with a structure shows that, in practical application, the safety and stability of the square storage battery with the structure of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com