Resin-cast rectangular dry-type transformer

A technology of dry-type transformers and resin casting, applied in the field of transformers, can solve the problems of complex structure of multi-level elliptical cross-section structure, increase of no-load loss and wire weight, and increase of transformer manufacturing cost, so as to shorten the length of magnetic circuit and improve market competition Force, reduce the effect of no-load loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

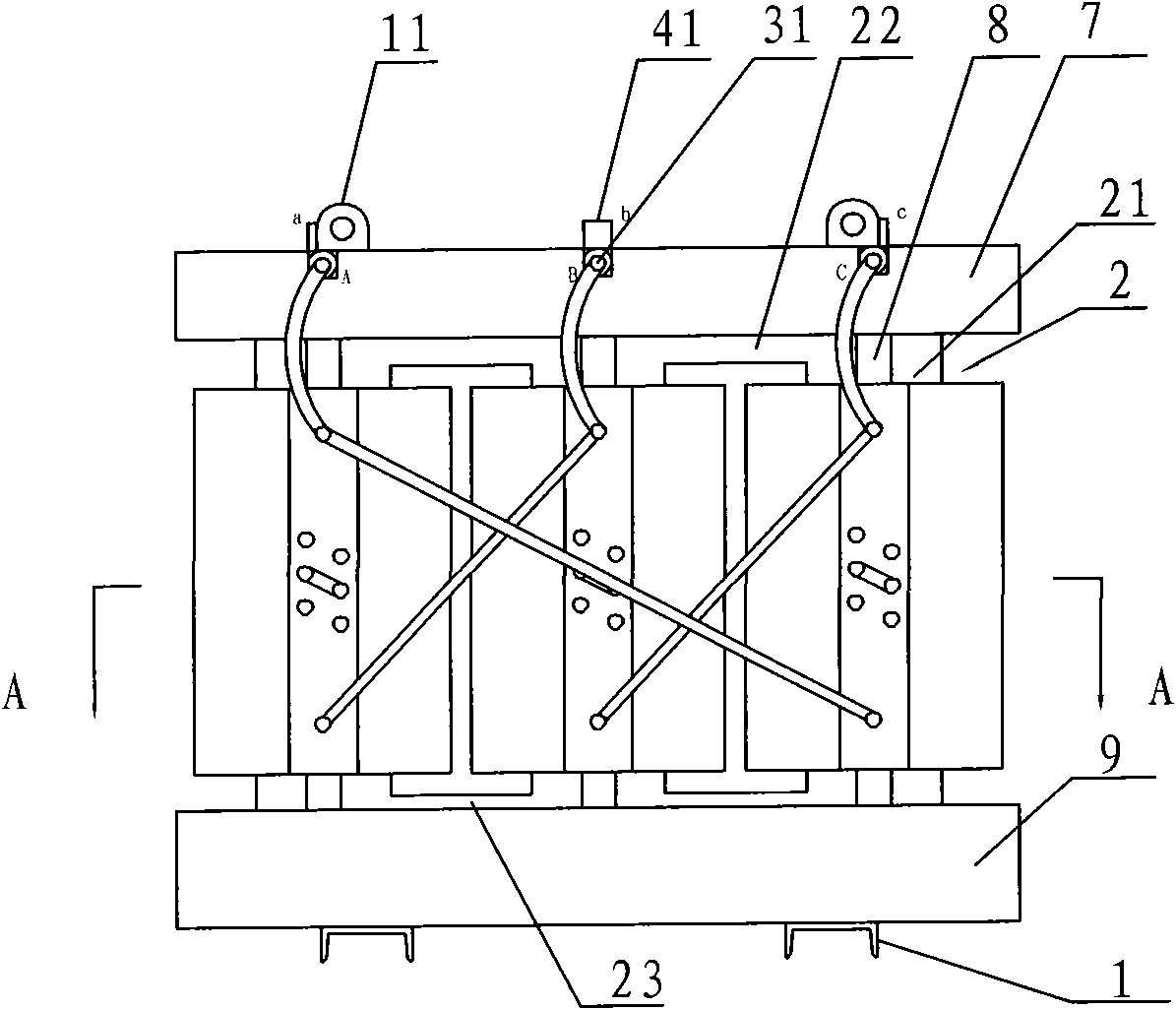

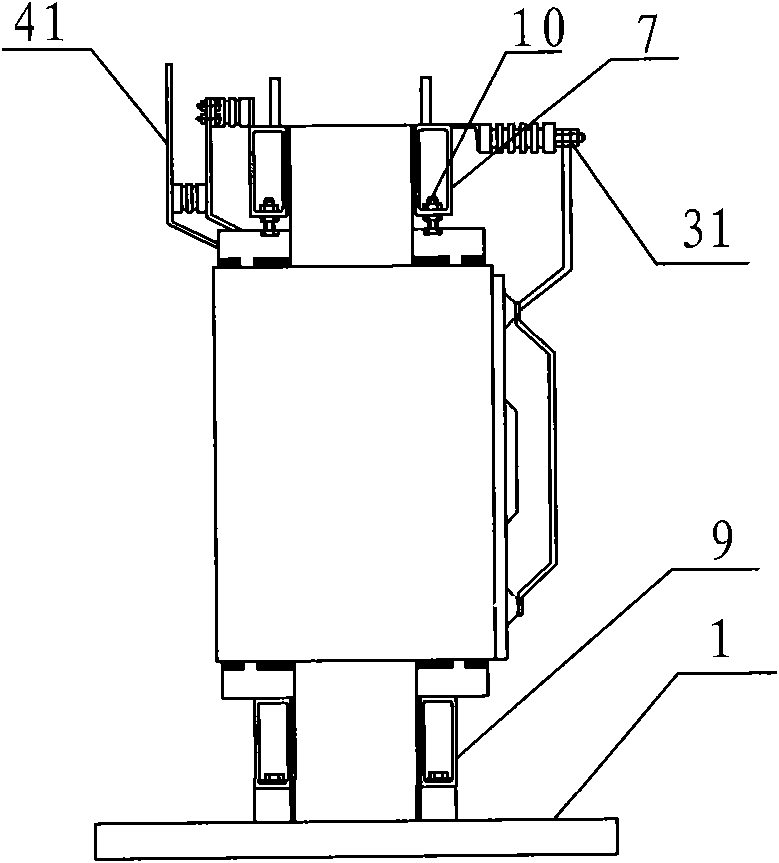

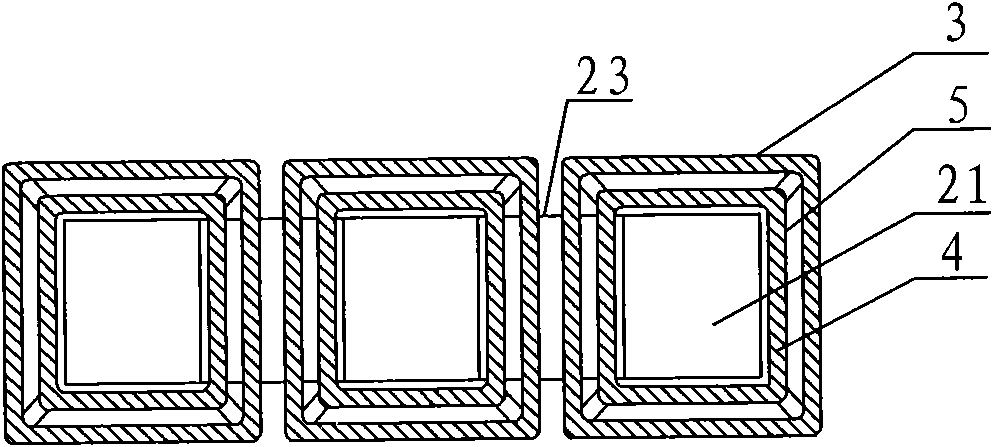

[0015] Such as figure 1 As shown, it is the front view of the resin casting rectangular dry-type transformer of the present invention, which is composed of a bracket 1, an iron core 2, a high-voltage coil 3 and a low-voltage coil 4 arranged outside the iron core, and the iron core 2 includes three mutually parallel The core column 21 is connected by the upper yoke 22 and the lower yoke 23. A low-voltage coil 4 is installed on the outside of each phase core column 21. The low-voltage coil 4 is wrapped with an insulating layer 5, and the high-voltage coil 3 is arranged outside the insulating layer 5; the high-voltage coil 3 is connected to a high-voltage terminal 31, and the low-voltage coil 4 is connected to a low-voltage terminal 41, and the low-voltage coils 4 of each phase are connected through copper bars;

[0016] figure 2 for figure 1 L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com