Method for jacking steel casting of bored pile by using jacks

A technology of bored cast-in-place piles and steel casings, which is applied to sheet pile walls, buildings, and foundation structure engineering. It can solve the problems that the working face may not meet the requirements, the static friction resistance is large, and there is no lifting force, so as to achieve turnover The effect of high utilization rate, easy control and slow stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

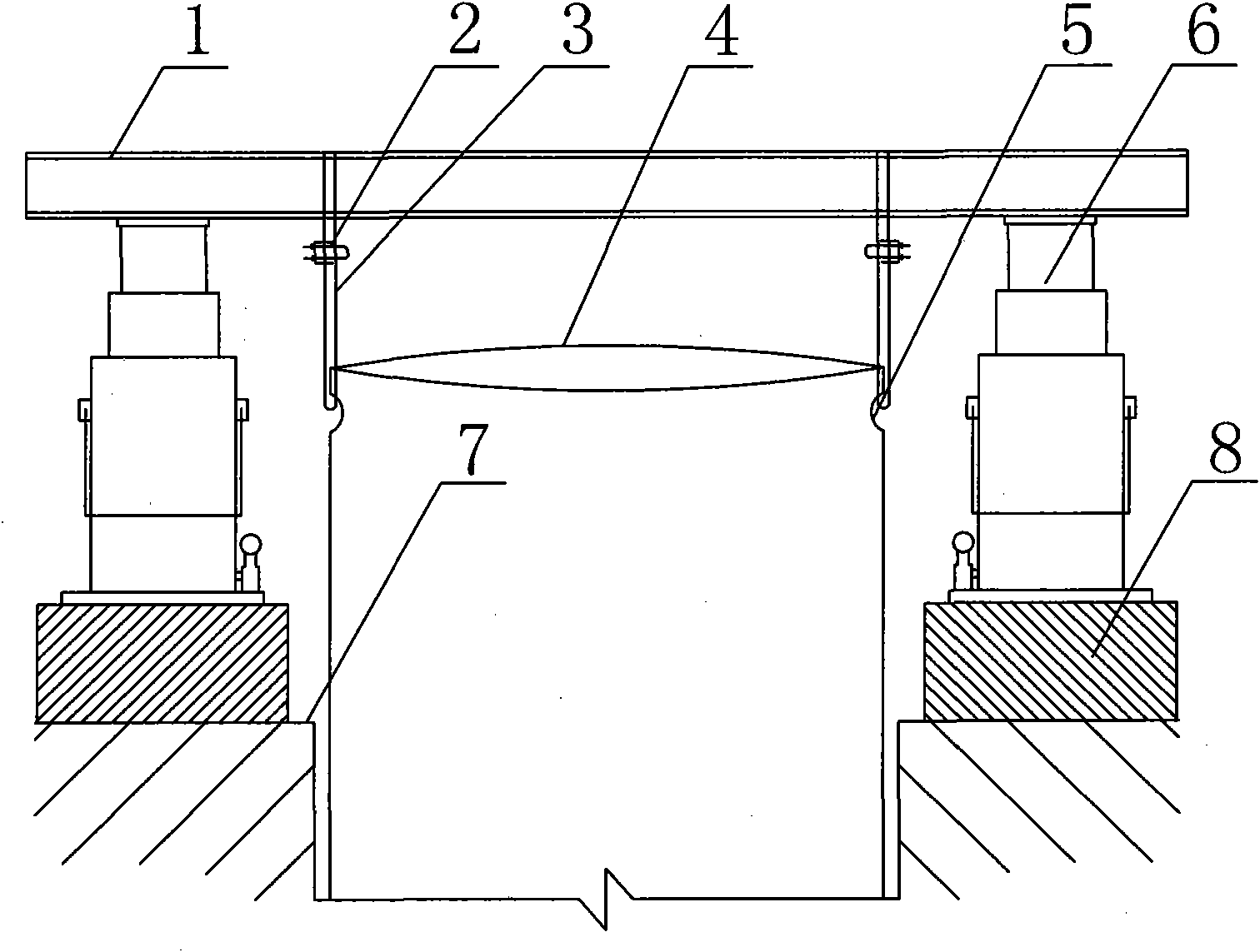

[0017] See Figure 1-2 , A method for pulling out the steel casing of a bored pile with a jack, which includes the following steps: a) Place two smooth sleepers 8 horizontally on the ground 7 on both sides of the steel casing 4 being pulled out, so The connecting line of the two lifting lugs 5 of the steel protective tube that the two sleepers are pulled up vertically; b) A jack 6 is placed on each sleeper, and a beam 1 is set on the two jacks (I-steel can be selected), each A steel wire rope 3 is provided on the beam above the lifting lugs. The steel wire rope passes through the lifting lugs of the steel casing and is fixedly connected to the two free ends of the steel wire rope; The two free ends are connected; c) Two people shake the jack at the same time, the jack lifts up the beam, and the beam pulls up the steel protective tube through the wire rope. The steel guard tube only needs to be pulled out. After the pull out, the static friction resistance is converted into dyn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com