Continuous dehydrating production process and device for nitro-cotton

A production process and nitrocellulose technology, applied in the field of dehydration, can solve the problems of many human factors, high labor intensity, low production efficiency, etc., and achieve the effects of good uniformity of water and wine content, reduction of alcohol consumption, and reduction of labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

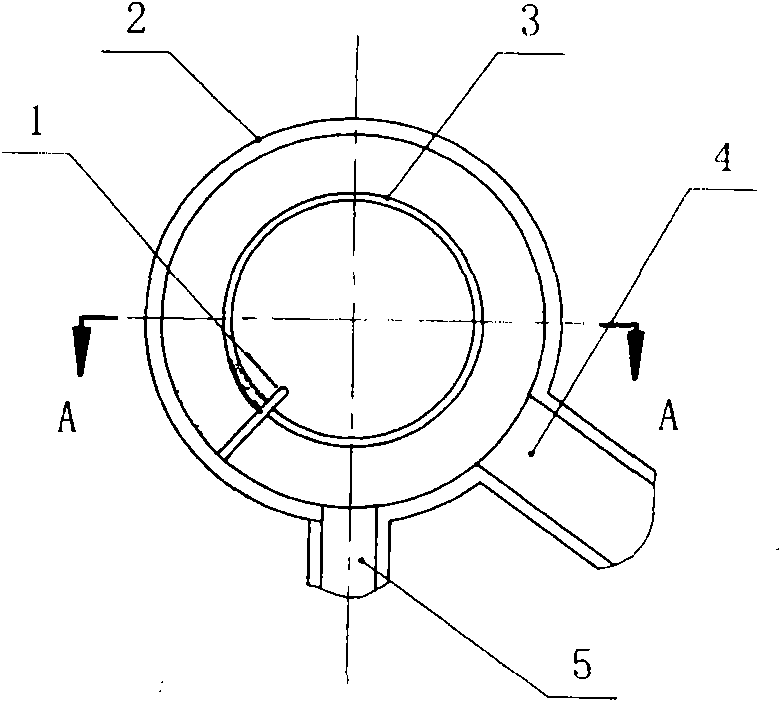

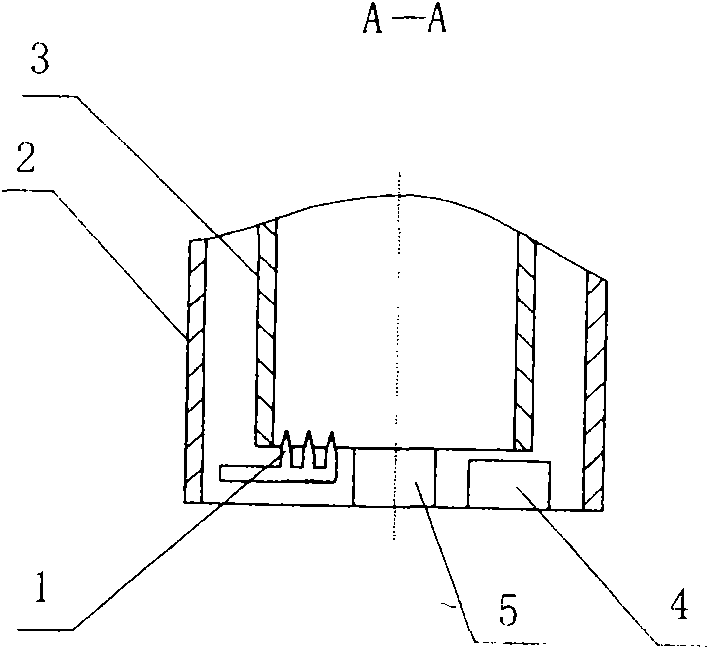

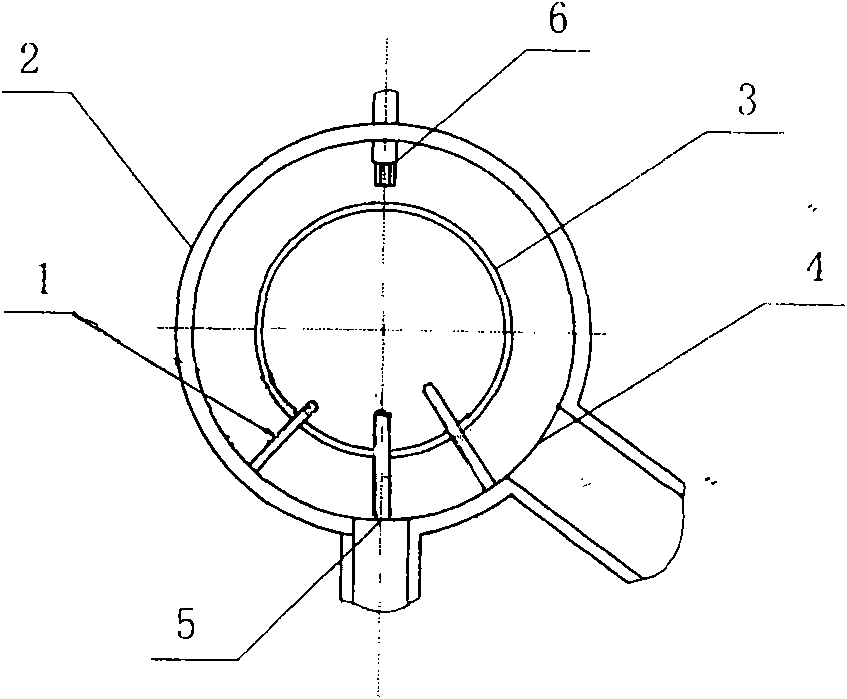

[0028] Such as figure 1 , figure 2 As shown, the horizontal centrifuge is provided with at least one decompression hook 1 at the outlet end of the common horizontal centrifuge. The decompression hook is provided with at least one hook head at the end of the rod body, and the tail end of the rod body is fixed on the centrifuge. On the housing 2, the hook head stretches to the inside of the screen cloth 3. The lower part of the horizontal centrifugal deflagging machine is provided with a water outlet 5, and the bottom right is provided with a discharge port 4. The decompression hook is arranged upstream of the discharge port 4. Discharge. In order to improve the defibration effect, three or more defibrillation hooks can be set in the horizontal centrifugal decontamination machine, and three or more hook heads can also be arranged on each defibration hook. When a plurality of release hooks are arranged, the rod body tail ends of each release hooks are respectively fixed on th...

Embodiment 1

[0031] Production process of continuous dehydration of nitrocellulose for L-shaped paint ( Figure 4 shown):

[0032] ① Use the first cotton delivery pump 8 to send the water-containing nitrocellulose from the storage container 7 into the horizontal centrifugal disintegrator 9 for dehydration and disintegration. figure 1 , figure 2 As shown, the horizontal centrifuge is provided with a decompression hook 1 at the outlet end of the horizontal centrifuge, and the decompression hook is provided with three hook heads at the end of the rod body, and the tail end of the rod body is fixed on the centrifuge. On the housing 2, the hook head stretches to the inside of the screen cloth 3. In this step, the rotating speed of the horizontal centrifuge is 1200 rpm. The nitrocellulose was dehydrated in a centrifuge for 4 minutes. The water content of the dehydrated and decomposed nitrocellulose is 30%.

[0033] ②Put the nitrocellulose output from the outlet of the horizontal centrifuga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com