Dialkyl metal phosphinate and synthesis process of fire retardant thereof

A dialkylphosphinic acid, a synthesis technique, applied in the fields of compounds, chemical instruments and methods, organic chemistry, etc. of Group 5/15 elements of the periodic table, achieving good thermal stability, simple preparation method, and mild reaction conditions Effect

Active Publication Date: 2010-09-15

HONGHU YITAI TECH CO LTD

View PDF4 Cites 55 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is exactly for the defective of existing dialkyl phosphinic acid metal salt preparation method, the synthetic technique of dialkyl phosphinic acid metal salt flame retardant is provided, and it is as initial raw material by methyl dichloride phosphorus, and this The synthesis process can be carried out smoothly without complicated purification steps, so that dialkyl phosphinate can be prepared in a simple way, and the by-products generated during the reaction can be recycled and used without pollution to the environment

suitable for industrial production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

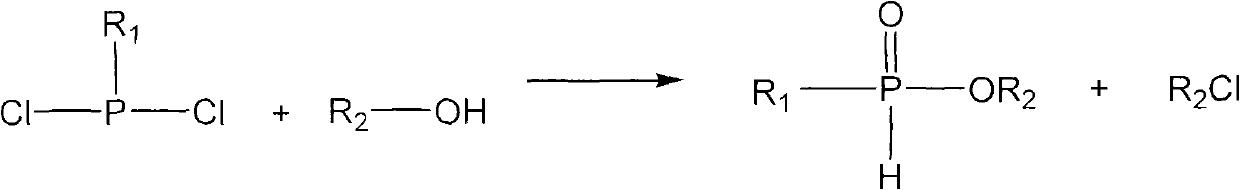

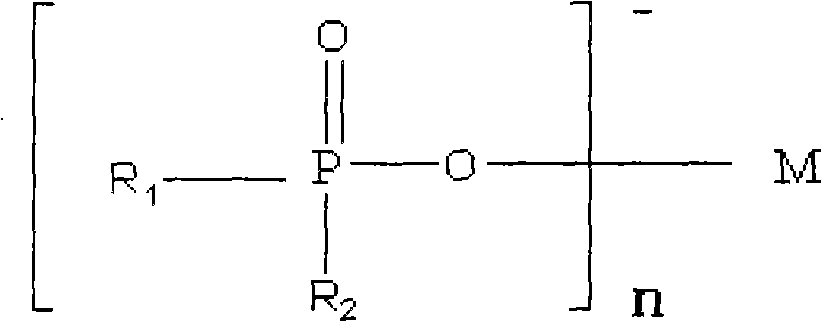

The invention relates to a preparation method of a fire retardant, in particular to a dialkyl metal phosphinate and a synthesis process of a fire retardant thereof. The dialkyl metal phosphinate has a structural formula described in the specification, wherein R1 represents alkyl, M represents metal ions, n represents an integer from 1 to 3, and R2 represents olefin of aliphatic series. The preparation method comprises the steps of: reacting alkylphosphonous dichloride with alcohol to obtain monoalkyl phosphate; carrying out radical reaction on the monoalkyl phosphate with olefin to obtain dialkyl ester phosphinate; and reacting the dialkyl ester phosphinate with lewis acid to obtain the dialkyl metal phosphinate fire retardant. The invention has mild reaction condition; the prepared product has good thermal stability and high yield, wherein the yield can reach 87.6 percent by the count of methyl butyl ester phosphate; and the preparation method is suitable for industrialized production.

Description

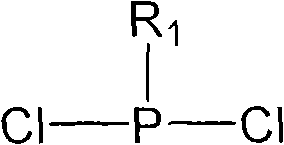

technical field The invention relates to a preparation method of a flame retardant, in particular to a synthesis process of a dialkylphosphinic acid metal salt and the flame retardant. Background technique Dialkylphosphinates can be used as flame retardants. Dialkylphosphinate flame retardant products have lower density, less flame retardant dosage, better mechanical properties, better color and lower smoke density. CTI (compared to tracking index) has a high value (up to 600V), which has great application prospects in the electrical and electronic industry, and is especially suitable for thin-walled electronic components, transparent sheets and films. In addition, metal phosphinates have been studied from the perspectives of toxicology and environmental protection, and it has been found that they do not have any adverse effects. The structural formula of dialkyl hypophosphite is as follows: As early as the late 1970s and early 1980s, the Pennwalt Company of the United ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07F9/30

Inventor 刘继延沈道胜许华堂刘学清

Owner HONGHU YITAI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com