Explosion-proof iron runner castable

A castable for iron trough, castable technology, applied in the field of refractory materials, can solve the problems of high labor intensity, frequent maintenance, low volume density, etc., achieve the effect of enhancing the safety factor of use, reducing the labor intensity of workers, and improving the quality of molten iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

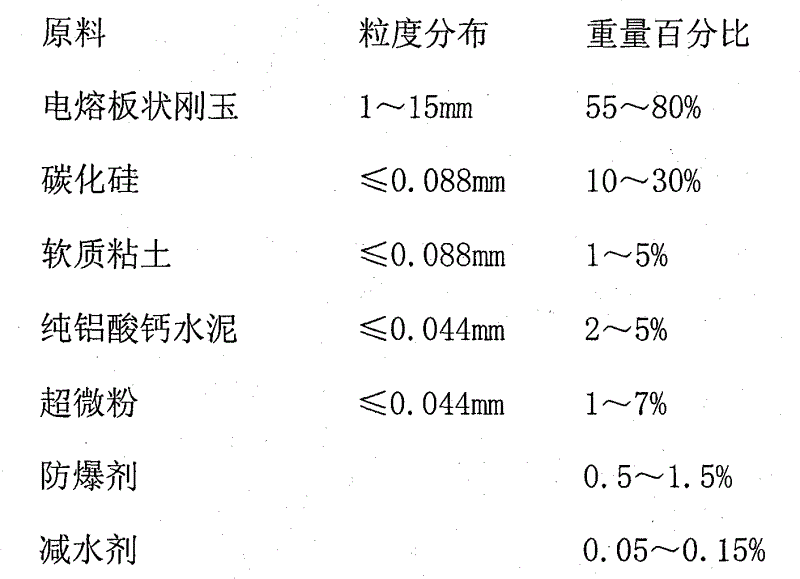

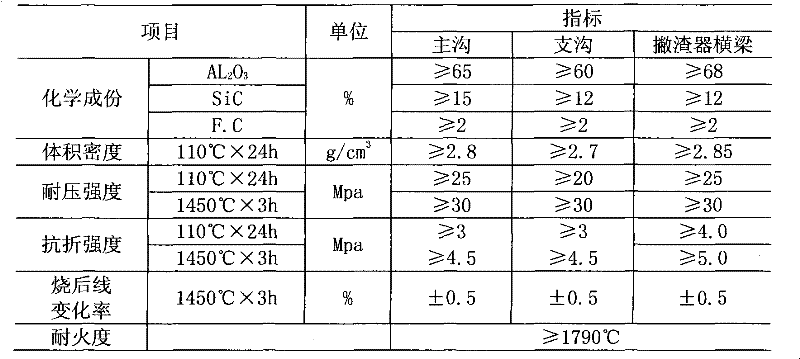

Method used

Image

Examples

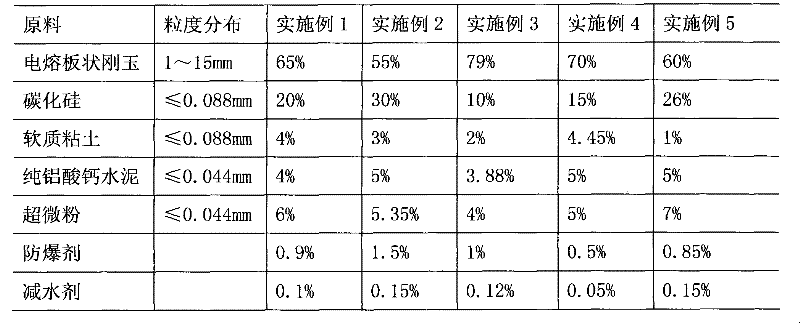

Embodiment 1

[0028] Embodiment 1 A kind of explosion-proof iron ditch castable, by weight percentage, raw material composition is shown in Table 2, and wherein anti-explosion agent is aluminum powder, basic aluminum lactate, anti-explosion fiber, boron carbide powder is 1.5: 3: 2 by weight: 3 mixture; explosion-proof fiber is polypropylene fiber, its diameter is 4 ~ 6μ, length is 3 ~ 5mm; ultrafine powder is active Al 2 o 3 Ultrafine powder, SiO 2 The superfine powder is a mixture of 4:2 by weight; the water reducer is a 1:1 mixture of polycyanamide condensate and sulfonate formaldehyde condensate.

[0029] The above-mentioned pouring preparation process is as follows: raw material selection-weighing according to the formula-mixing-stirring-discharging and bagging-storage, and water is added according to 5-5.5% of the total pouring raw material weight during use. When discharging and stirring, add the same material to the mixer each time, and add water strictly according to the standard....

Embodiment 2

[0033] Embodiment 2 A kind of castable of explosion-proof iron trough, by weight percentage, raw material composition is shown in Table 2, wherein anti-explosion agent is aluminum powder, aluminum lactate, anti-explosion fiber, boron carbide powder is 1: 2.5: 1: 2 by weight ratio Mixture; the explosion-proof fiber is a mixture of polyethylene and polypropylene fibers, with a diameter of 4-6μ and a length of 3-6mm; the ultrafine powder is active Al 2 o 3 Ultrafine powder, SiO 2 The superfine powder is a mixture of 3:2 by weight; the water reducer is a mixture of ADS and ADW in any ratio. Others are with embodiment 1.

Embodiment 3

[0034] Embodiment 3 A kind of castable for explosion-proof iron trough, by weight percentage, raw material composition is shown in Table 2, wherein anti-explosion agent is aluminum powder, aluminum lactate, anti-explosion fiber, boron carbide powder by weight ratio is 2: 4: 2.5: 4 Mixture; explosion-proof fiber is polypropylene fiber, its diameter is 4 ~ 6μ, length is 3 ~ 6mm; ultrafine powder is active Al 2 o 3 Ultrafine powder, SiO 2 The superfine powder is a mixture of 5:2 by weight; the water reducer is a mixture of polycyanamide condensate and sulfonate formaldehyde condensate. Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com