High-efficiency full-closed sludge treatment system and method thereof

A treatment method and fully enclosed technology, which is applied in dehydration/drying/thickened sludge treatment, sewage/sludge fertilizer, application, etc., can solve the problems of less fixed investment, less land occupation, and low treatment cost, so as to reduce investment , reduce processing costs, and eliminate odor effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail with an embodiment below, but it should be noted that the protection scope of the present invention is not limited thereto.

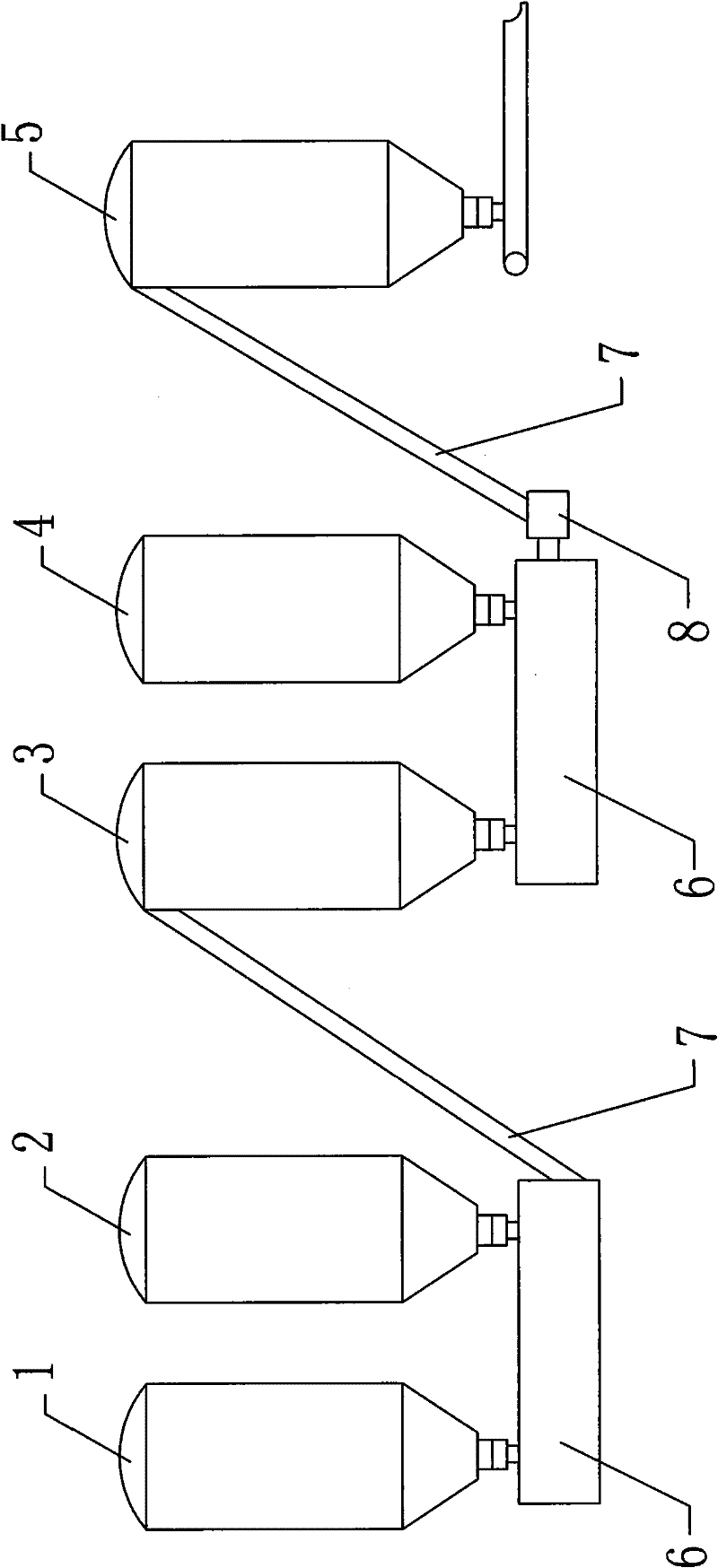

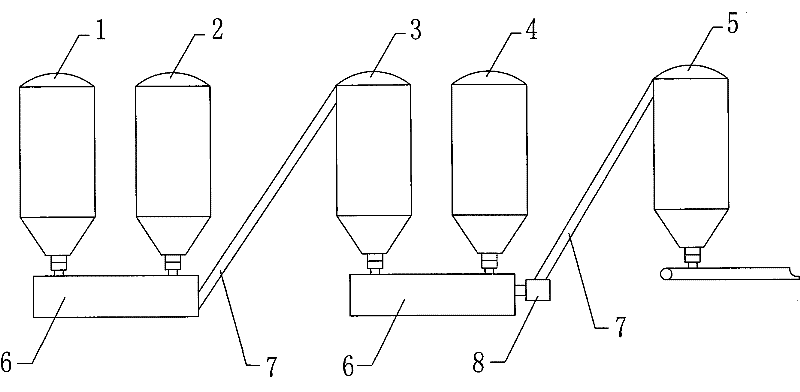

[0022] refer to figure 1 , a sludge efficient fully enclosed treatment system, which includes a sludge bin 1, a quicklime powder bin 2, a mixer 6, a screw conveyor 7, a digestion bin 3, a powdery organic storage bin 4, a granulator 8 and a finished product bin 5, The sludge in the sludge silo 1 and the quicklime powder in the quicklime powder silo 2 are agitated by the mixer 6, and the mixture formed by stirring with the mixer 6 is transported to the digestion silo 3 by the screw conveyor 7, and the above-mentioned mixture in the digestion silo 3 and the powdery organic storage silo 4 The powdery organic matter is stirred by the mixer 6 and then granulated by the granulator 8, and then transported to the finished product warehouse 5 by the screw conveyor 7.

[0023] A kind of sludge high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com