Manufacturing equipment and manufacturing process for spherical sulfur granules

A sulfur granule and manufacturing equipment technology, applied in the direction of liquid separation into beads and granulation, sulfur compounds, inorganic chemistry, etc., can solve the problems of large sulfur production capacity, large floor area, and inapplicability of sulfur granulation production occasions, and achieve The effect of large production capacity and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

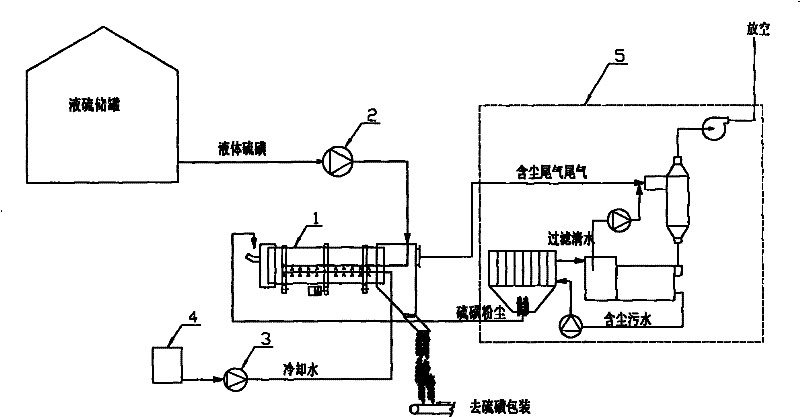

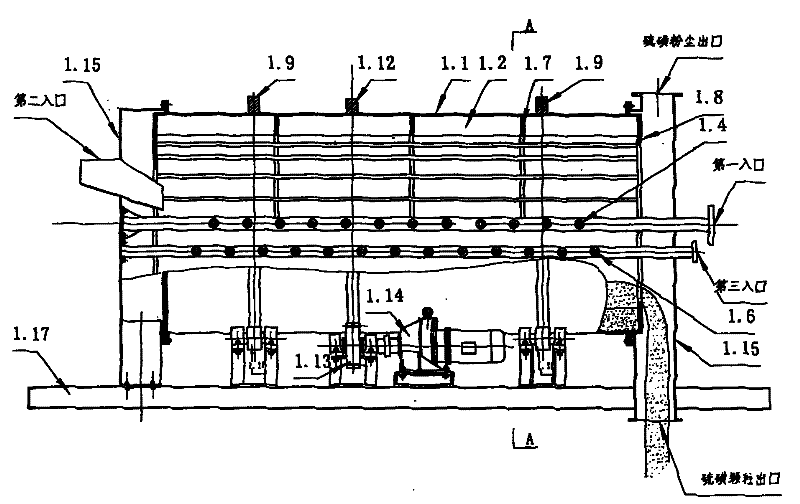

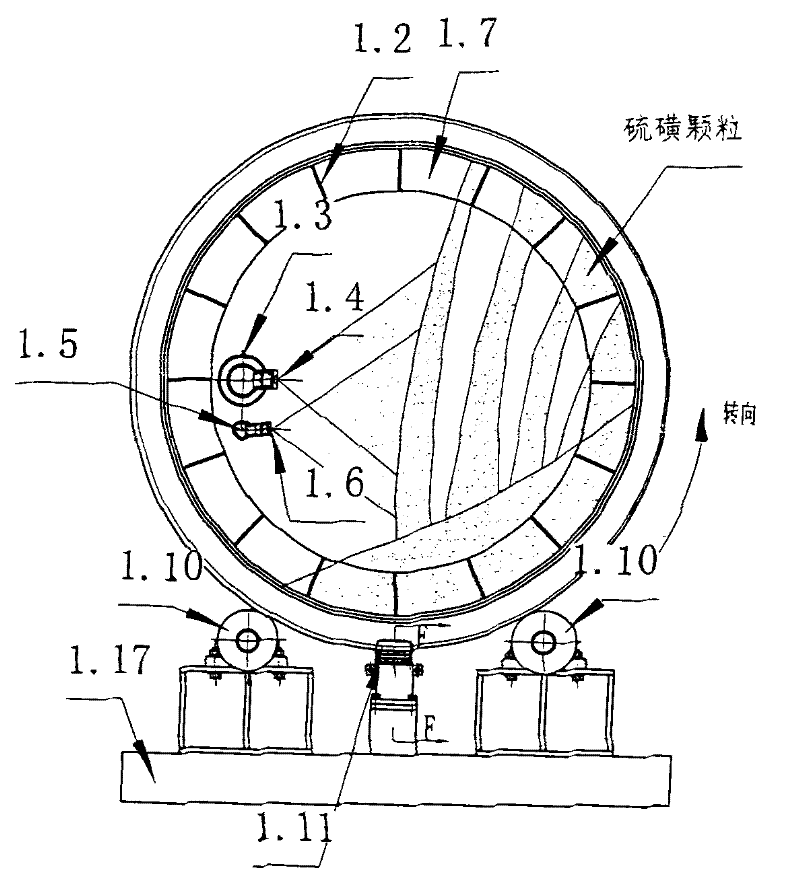

[0013] Control attached figure 1 , the manufacturing equipment of spherical sulfur granules, its structure is to include rotary drum sulfur granulator 1, liquid sulfur pump 2, cooling water pump 3, cooling water tank 4, water film dedusting unit 5, wherein the output end of liquid sulfur pump 2 is connected to the converter The first inlet of drum sulfur granulator 1, the outlet of solid sulfur in the water film dedusting unit 5 is connected to the second inlet of drum granulator 1, the inlet of cooling water pump 3 is connected to the outlet of cooling water tank 4, and the outlet of cooling water pump 3 The outlet is connected to the third entrance of the drum granulator 1, the outlet of the solidified sulfur particles of the drum granulator 1 is connected to the entrance of the product packaging section, and the outlet of the sulfur dust of the drum granulator 1 is connected to the water film dust removal unit 5 The induced draft fan 5.6 is pumped into the water film dust c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com