Novel powder impact damping honeycomb sandwich structure

A technology of honeycomb sandwich structure and impact damping, which is applied in the direction of layered products, etc., and can solve problems such as unstable performance, falling off, and easy aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

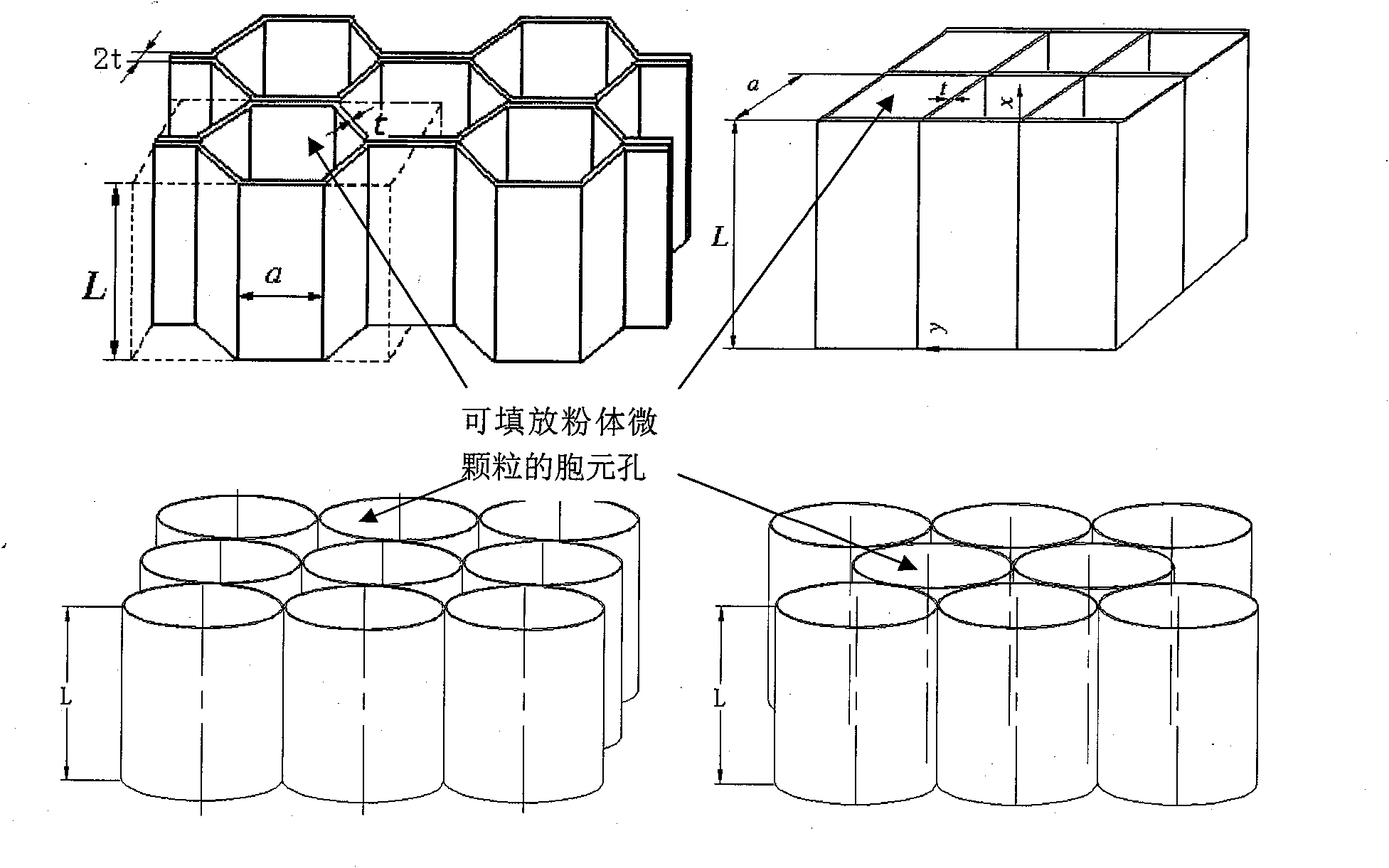

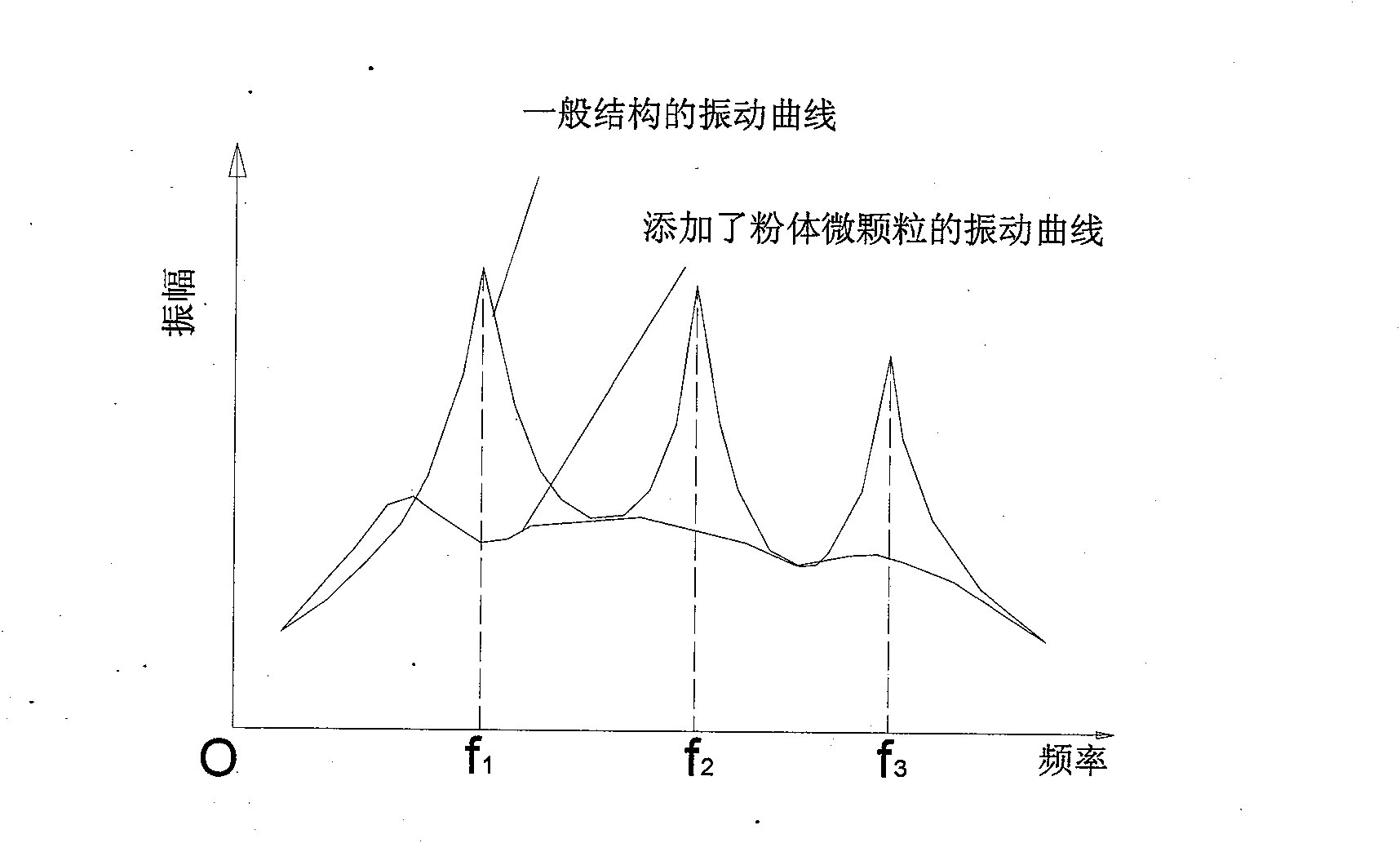

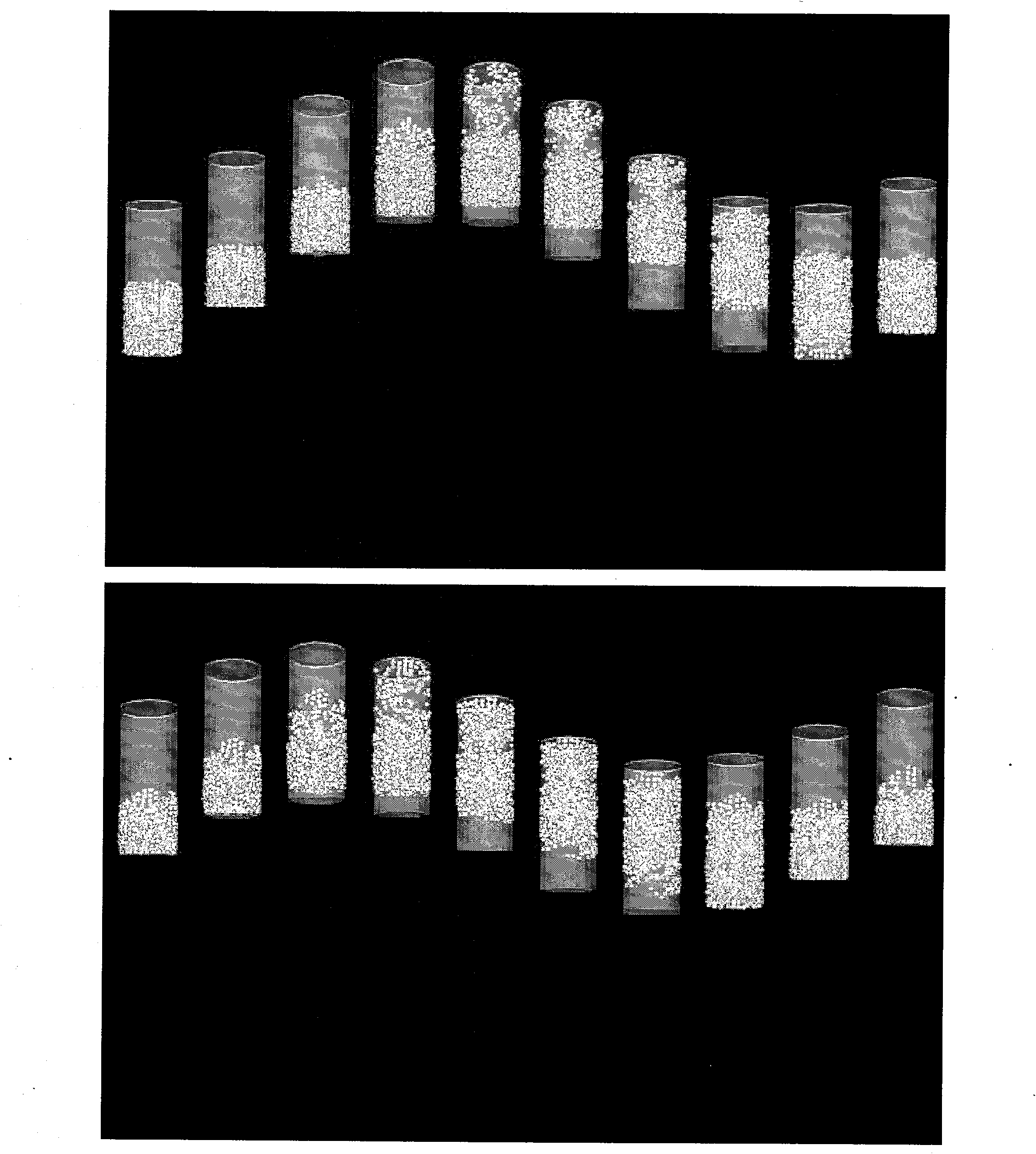

[0009] The invention is based on the powder vibration impact damping theory, and utilizes the structural characteristics of the honeycomb sandwich plate beam shell, and realizes large damping performance by consuming the vibration energy of the honeycomb sandwich structure through the impact of powder particles and dry friction. The implementation of the present invention is mainly divided into three parts. One is to determine the filling position of the powder microparticles in the honeycomb sandwich structure, that is, to use the natural structural characteristics of the honeycomb sandwich cells to fill the powder microparticles in the honeycomb at this position. In the sandwich cell, not only does not occupy the extra space of the structure, but also can improve the damping of the whole structure; the second is the selection of powder microparticle material and geometric parameters; the third is to determine the manufacturing process of the new structure. Therefore, the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com