Piston positioning and locking device

A positioning and locking piston technology, applied in the field of metal cutting, can solve the problems of affecting the machining accuracy of the piston, increasing the manufacturing cost of the piston, and inconvenient operation, etc., and achieves the effect of simple structure, low cost, and convenient clamping and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

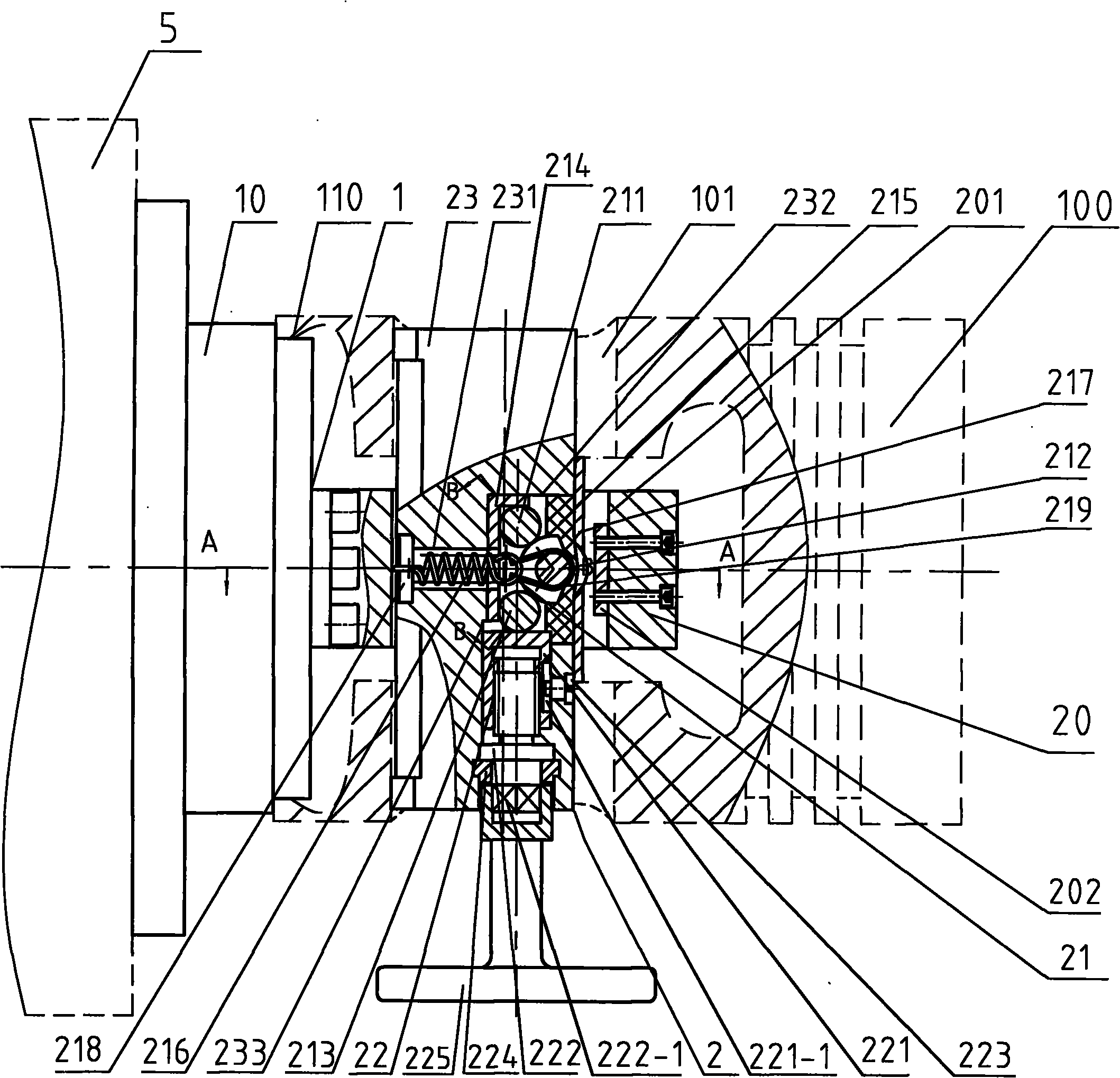

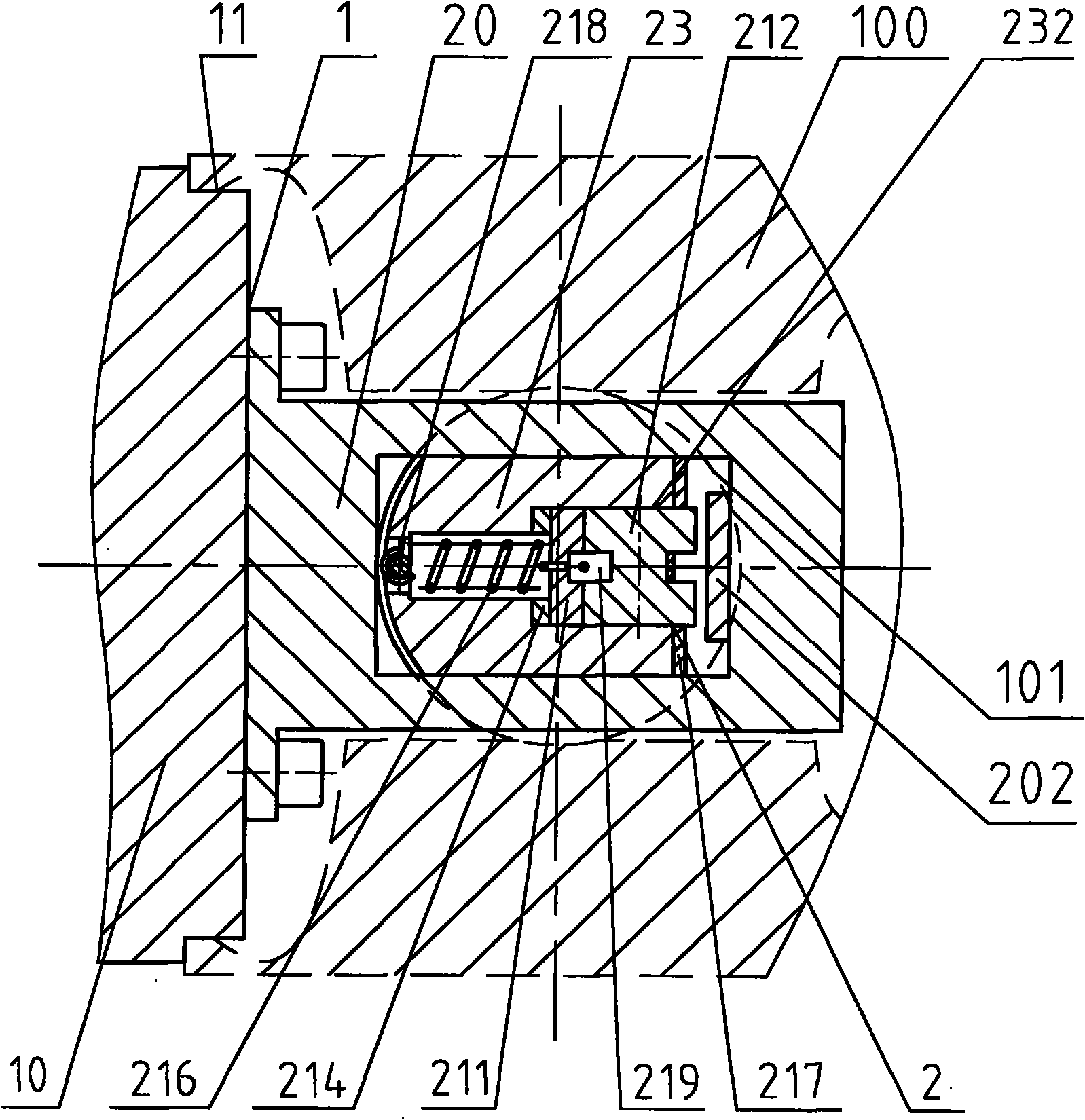

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

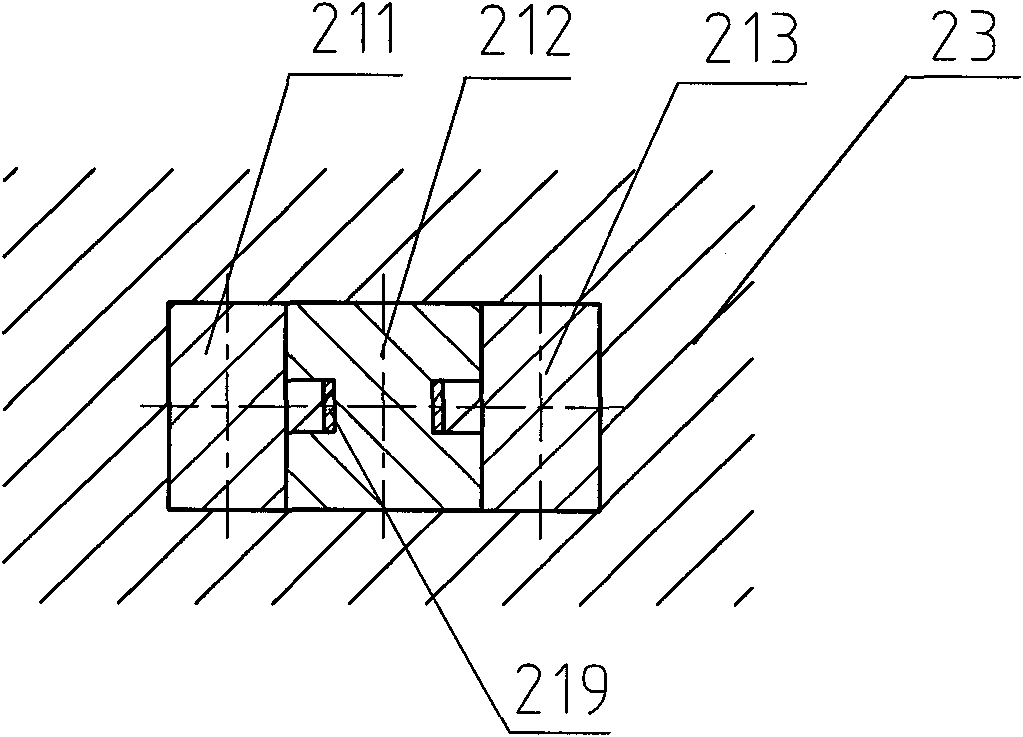

[0018] Such as Figure 1 ~ Figure 4 As shown, the present invention includes a positioning mechanism 1 and a locking mechanism 2. The positioning mechanism 1 includes a positioning tire 10 and a center-through seat 20. The positioning tire 10 of this embodiment is a stepped circular part, and one end thereof is fixed on a lathe fixture 5 The other end is embedded in the inner hole 110 at the bottom of the piston 100 . Piercing seat 20 is a cuboid, and its bottom both sides are fixed on the center of positioning round table 11 of positioning tire 10 by 6 fastening screws, and a rectangular cross hole 201 perpendicular to the axis of threading seat is provided in the middle of threading seat 20 . The locking mechanism 2 includes an elastic clamping mechanism 21, a screw propulsion mechanism 22, and a horizontal pin 23. The horizontal pin 23 is a long shaft member with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com