Flue gas denitration reactor

A technology for denitrification reactors and reactor shells, applied in the field of flue gas denitrification reactors with selective catalytic reduction method for internal heat preservation, can solve the problems of rising manufacturing costs, large amount of metal materials, and high heat preservation costs, and achieve increased structural safety , high durability and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

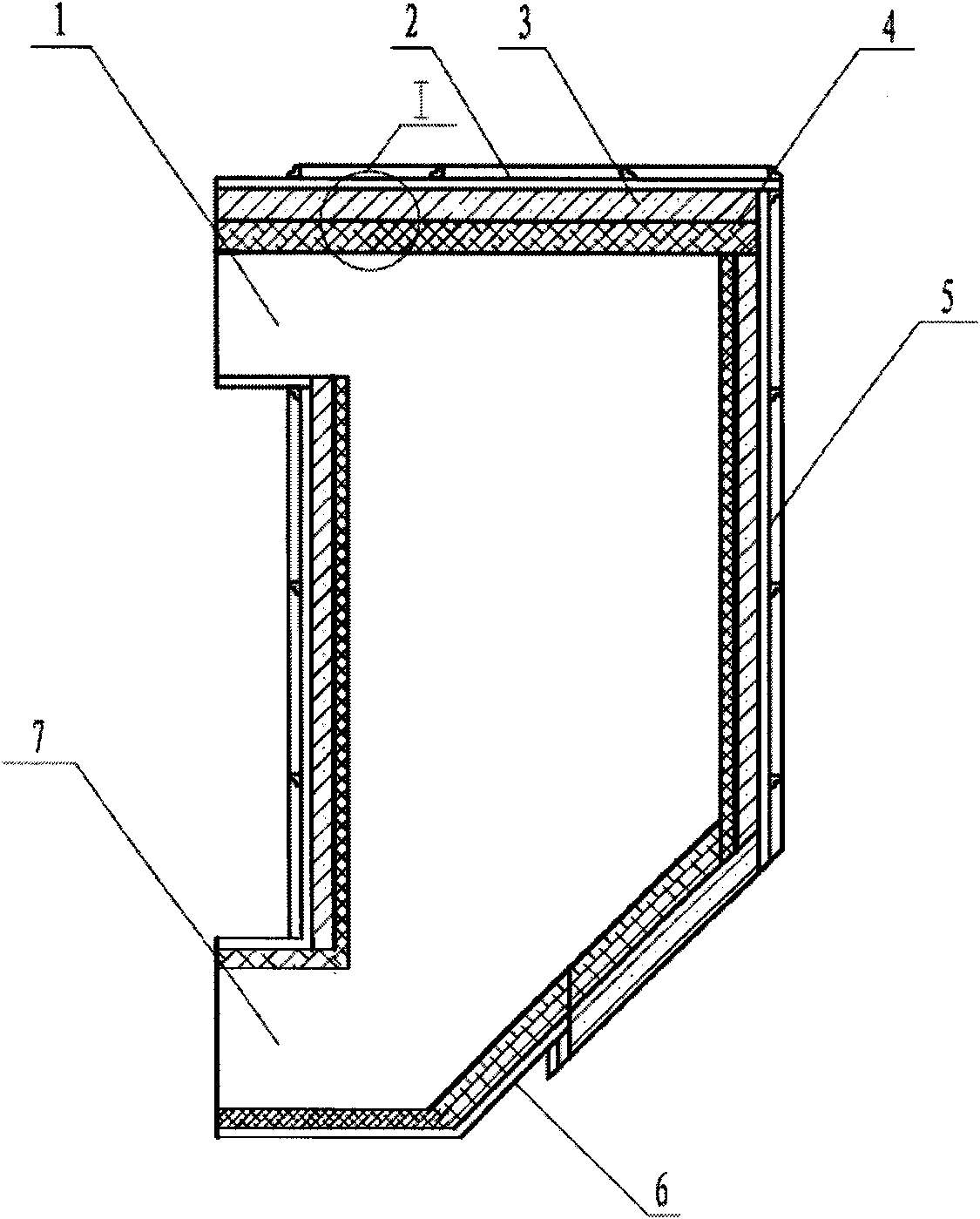

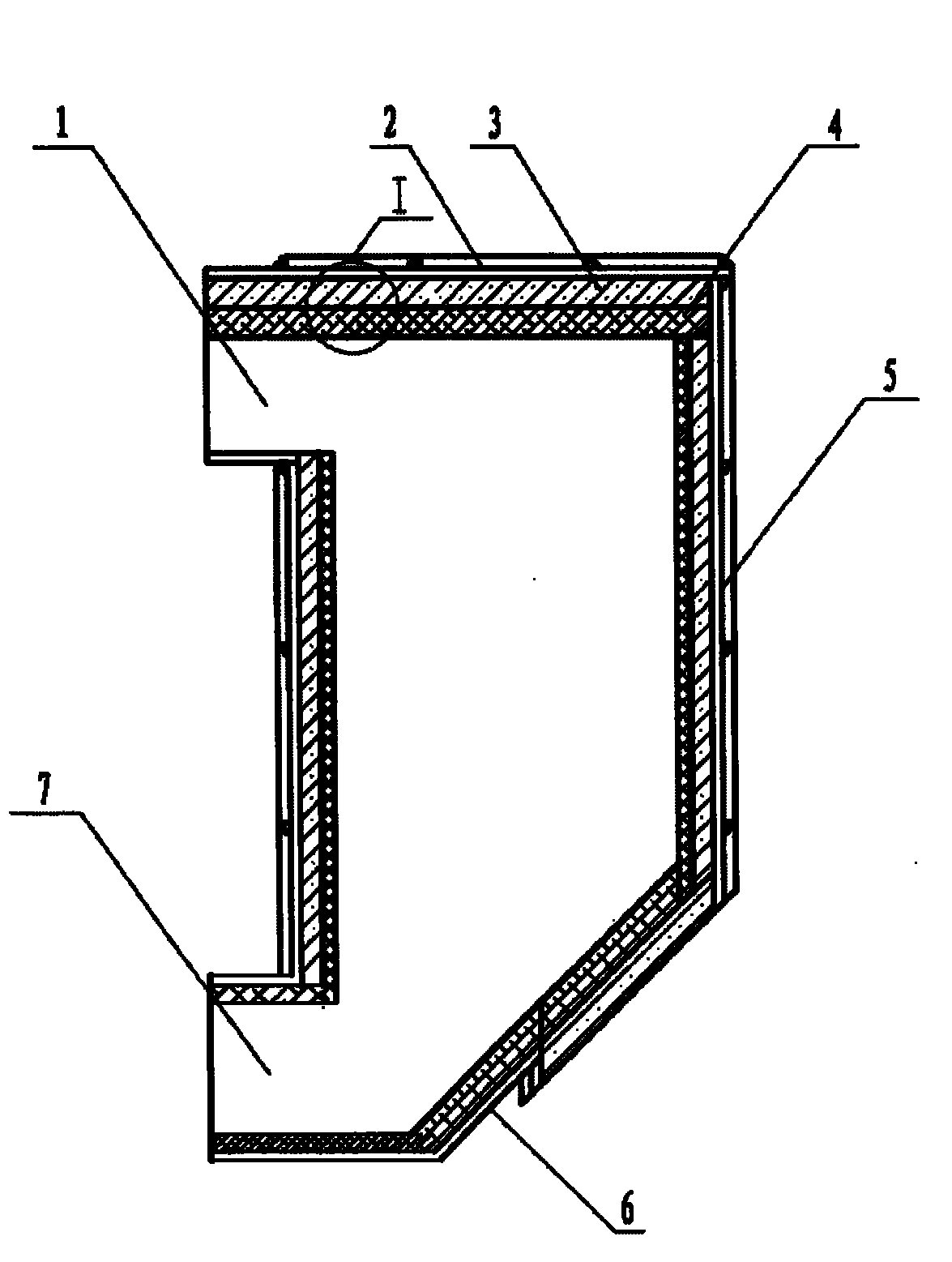

[0014] A flue gas denitrification reactor comprises a shell and an insulating layer laid on the inner wall of the shell.

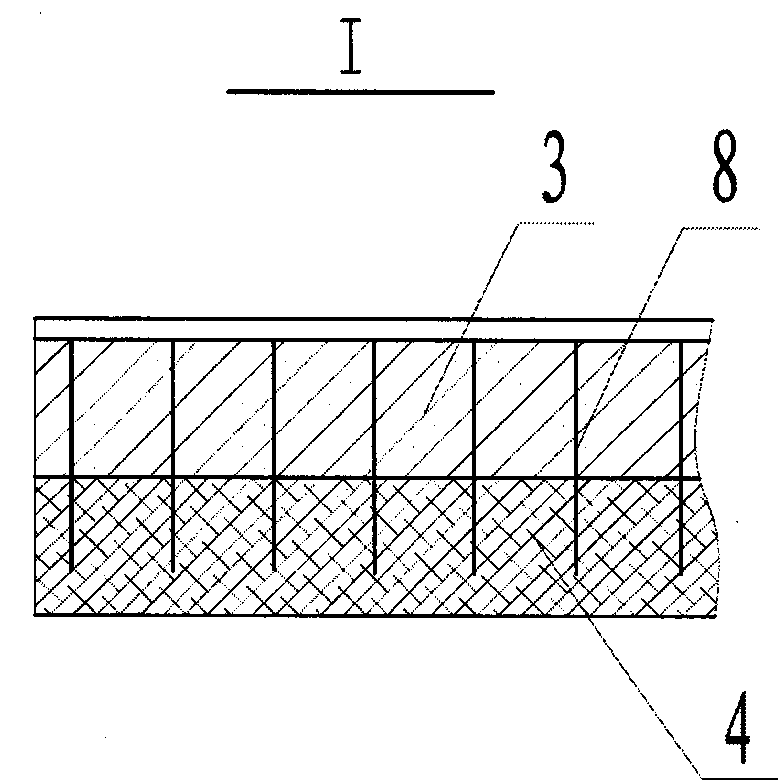

[0015] Preferably, the flue gas denitration reactor further includes a wear-resistant layer laid on the inner wall of the insulation layer.

[0016] Preferably, the housing includes a side plate, a top plate and an inclined plate respectively connected to the side plates, the top plate and the side plate jointly form a first opening, and the inclined plate and the side plate jointly form a second opening.

[0017] Preferably, the flue gas denitrification reactor is further provided with heat-resistant steel bars welded to the inner wall of the housing, and the insulation layer is fixed on the heat-resistant steel bars.

[0018] Preferably, the wear-resistant layer is also held on the heat-resistant steel bars.

[0019] see Figure 1 to Figure 2 As shown, the flue gas denitrification reactor of the present invention is applied to the flue gas denitrificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com