Radiation device with wind scooper

A technology of heat dissipation device and air guide cover, which is applied in the direction of cooling/ventilation/heating transformation, semiconductor devices, semiconductor/solid-state device components, etc., which can solve problems such as poor heat dissipation performance, improve airflow utilization, and facilitate disassembly and assembly , sufficient cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The substantive features of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

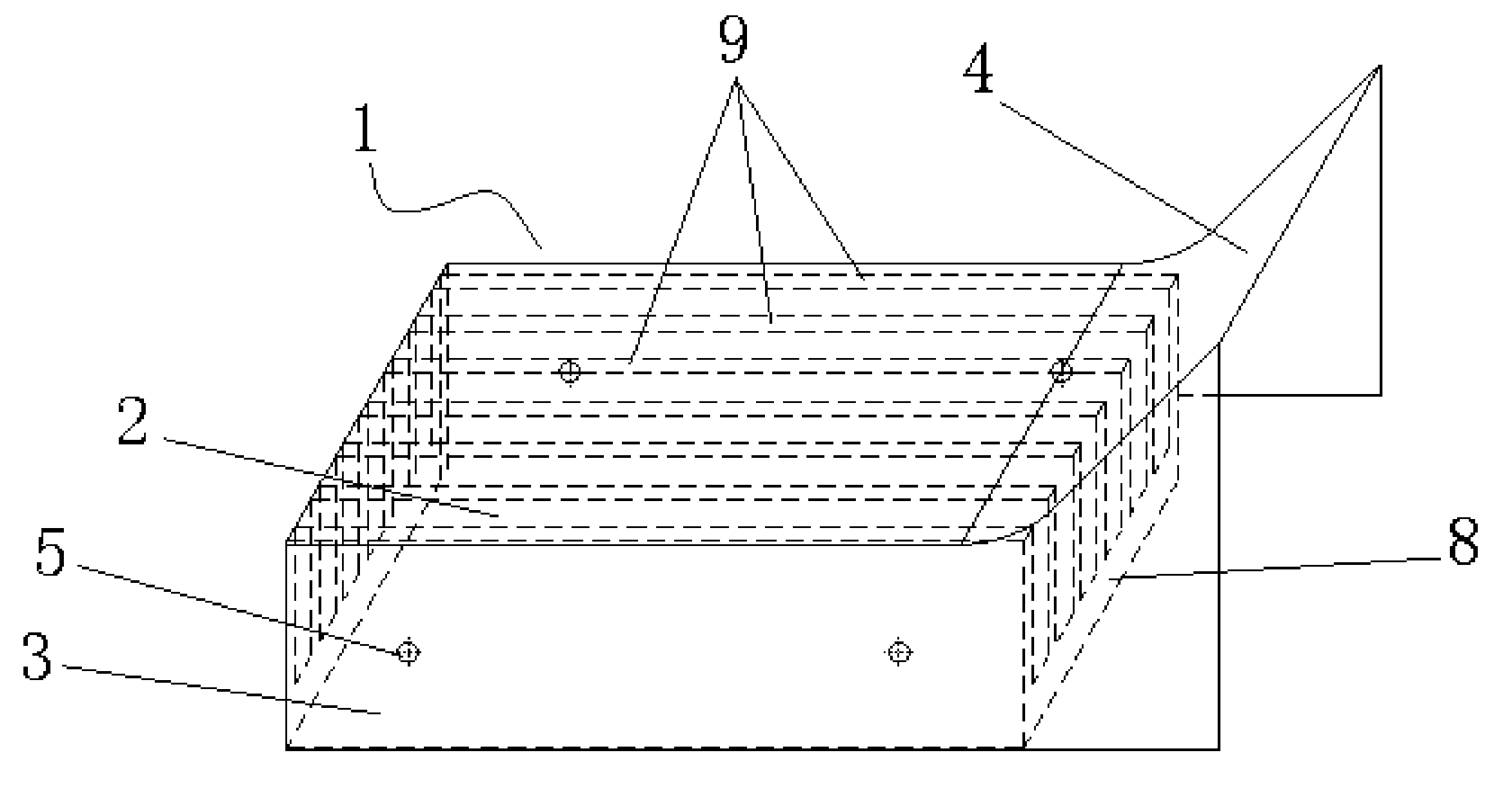

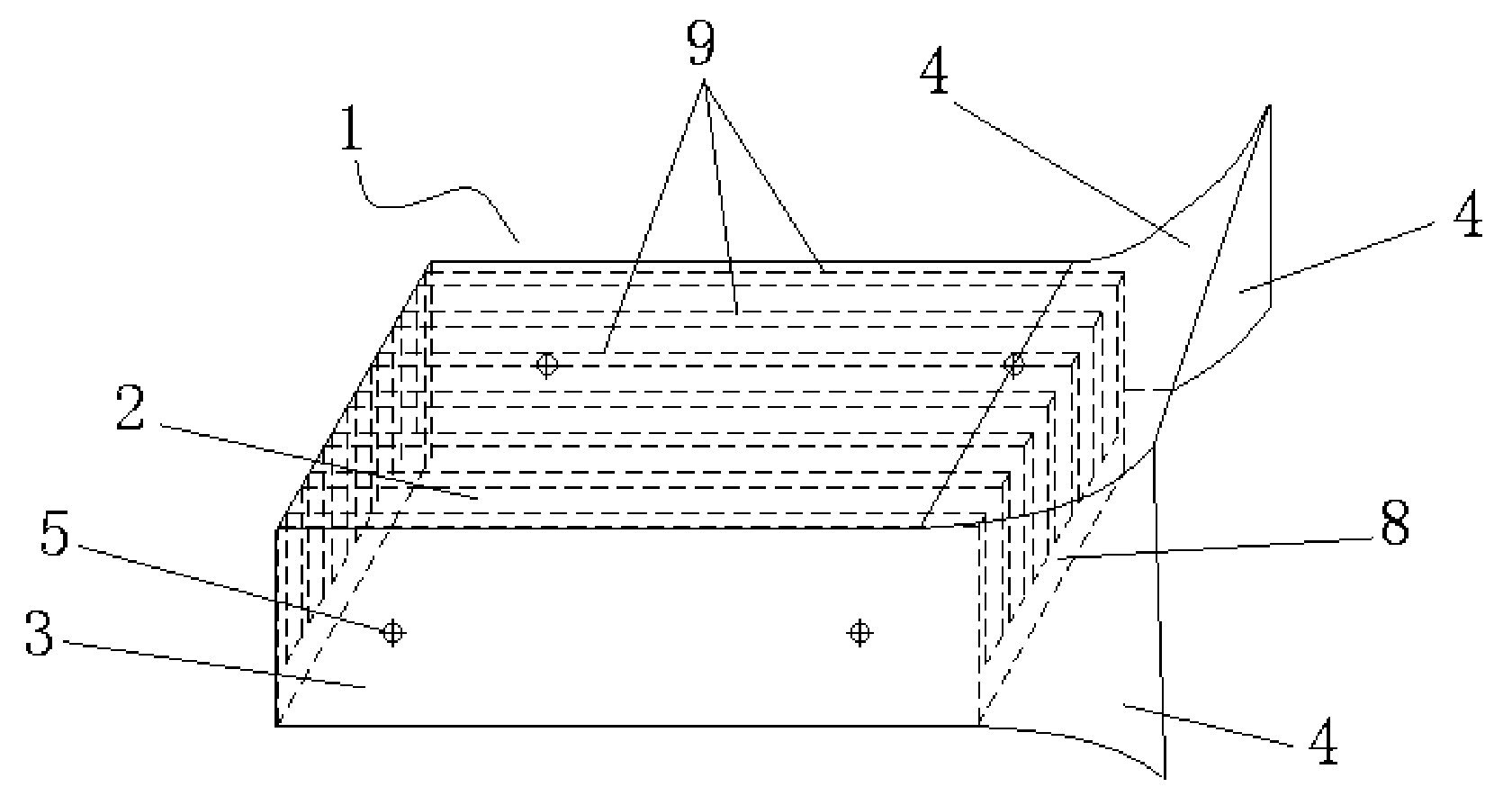

[0022] As shown in the drawings, a heat dissipation device with a wind guide cover includes a heat conduction base 8 and a heat dissipation fin group 9 arranged on it. The fin group 9 is rectangular, and each fin is arranged in parallel and at intervals. An airflow channel is formed between the fins, and the fins are extended from the heat conduction base 8 . A “∏”-shaped air guide cover 1 is sleeved on the periphery of the fin group 9, and one end of the air guide cover 1 is extended to form an air inlet with a flared surface 4, and the other end forms a “∏”-shaped air outlet. The above-mentioned airflow channel communicates with the air inlet and the air outlet, and the top surface of the air guide 2 is in conflict with the fin group 9 or forms a gap of ≤ 3mm. The entire air guide 1 can be made of iron sheet or pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com