Capacitance apparatus and system for measuring high voltage element voltage and gas insulated transformer substation

A technology of high-voltage components and capacitive equipment, which is applied in the direction of measuring electrical variables, measuring current/voltage, measuring devices, etc., to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

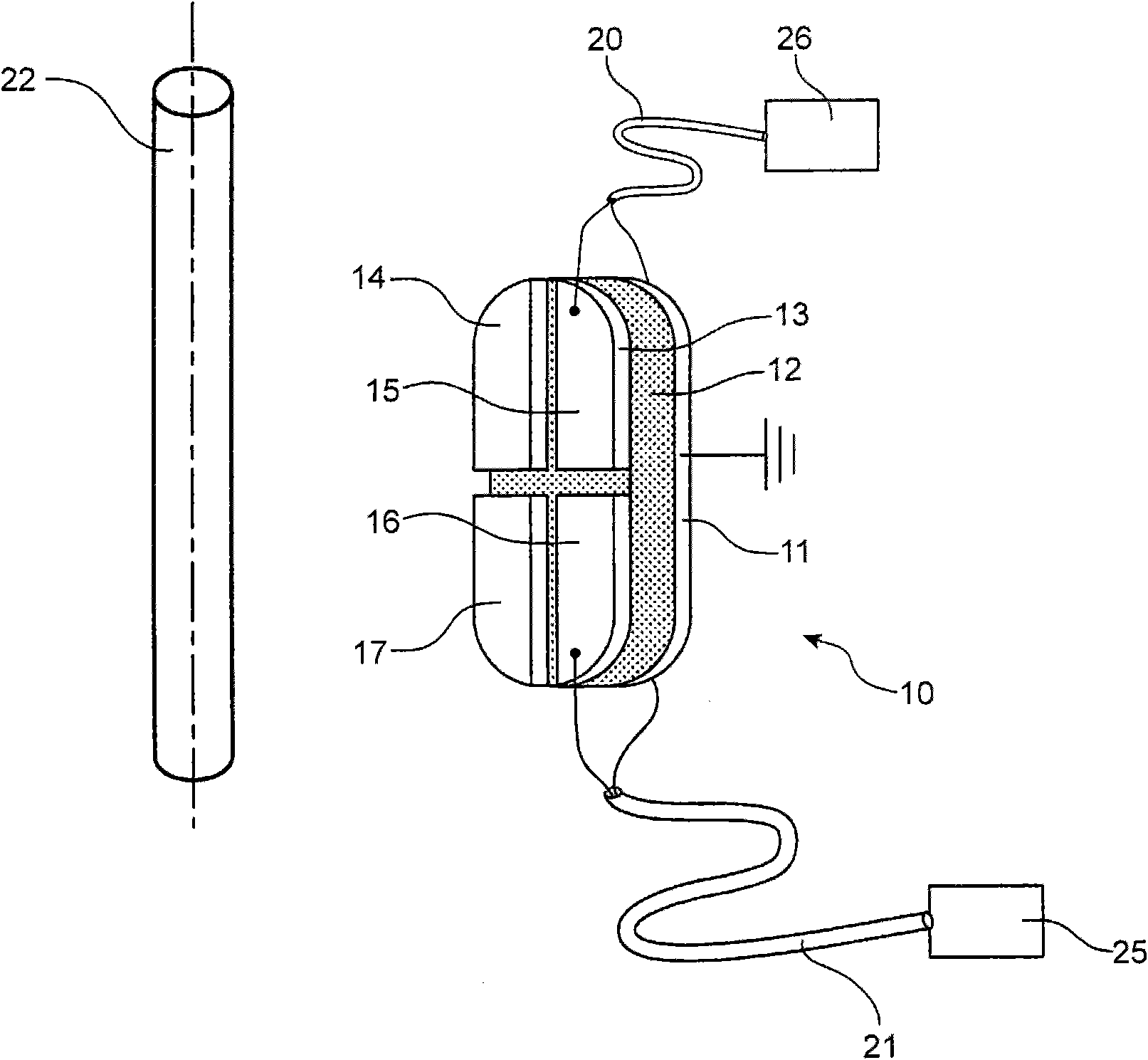

[0056] The device 10 of the present invention, such as figure 1 shown, consists of a printed circuit board consisting of three layers:

[0057] a first layer 11 is a conductive layer;

[0058] a second layer 12, made of insulating material, preferably epoxy, with a thickness of very high precision; and

[0059] A third layer 13 is a conductive layer.

[0060] The third layer 13 includes a plurality of conductive parts, such as figure 1 Four sections 14 , 15 , 16 and 17 are shown, each of which is arranged to be connected to at least one of two signal output cables 20 and 21 .

[0061] This first layer 11 is usually connected to ground potential. The third layer 13 faces a high voltage electrode 22, for example a conductor whose high voltage is to be measured. Due to the influence of the electric field generated by the high voltage electrode 22, this third layer 13 is connected to a voltage level slightly higher than ground potential.

[0062] The device 10 of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com