Method for operating an internal combustion engine

A technology for internal combustion engines and motor vehicles, which is applied in the direction of internal combustion piston engines, combustion engines, engine starting, etc., and can solve problems such as lack of braking boost and adverse effects of brake booster functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

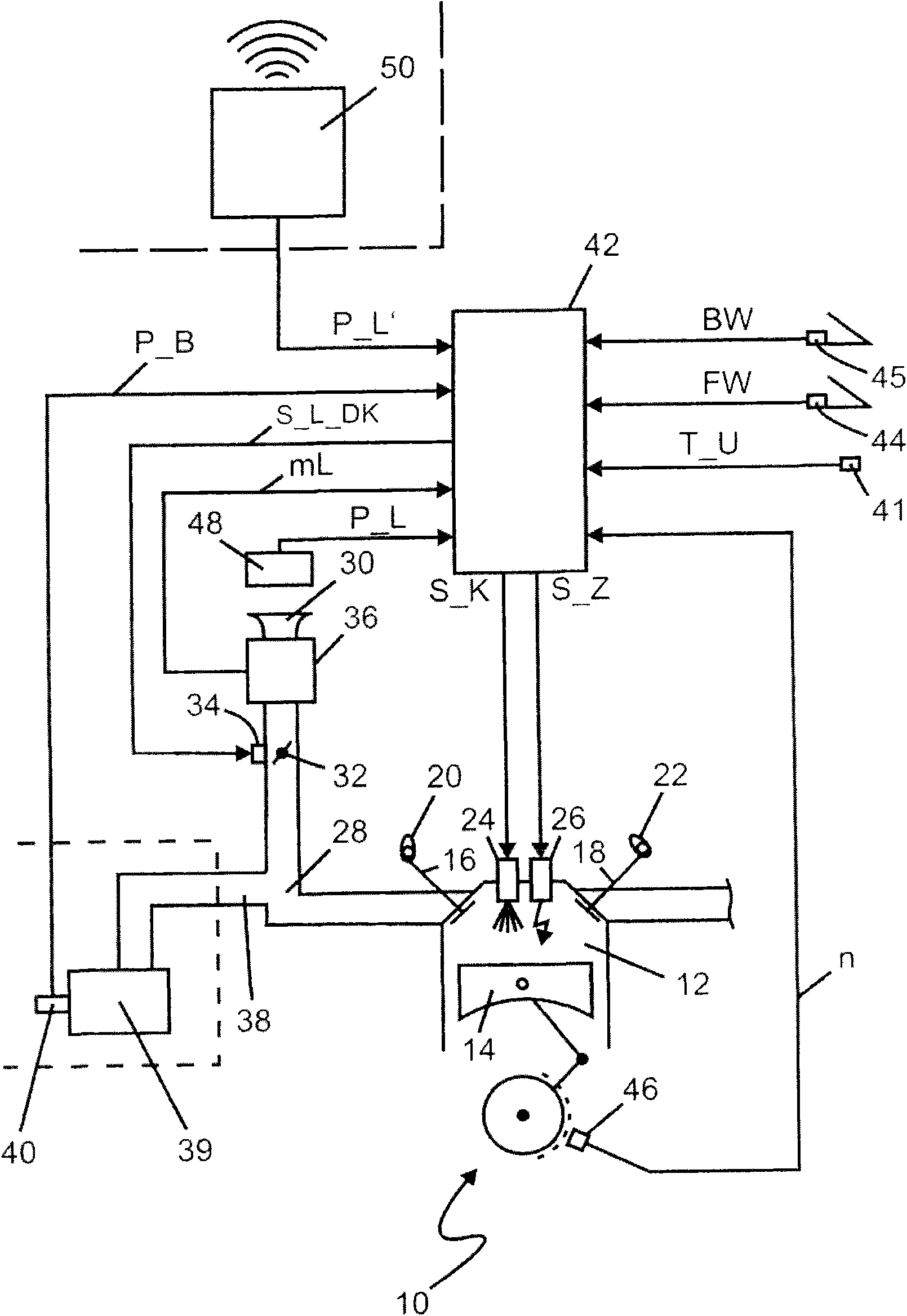

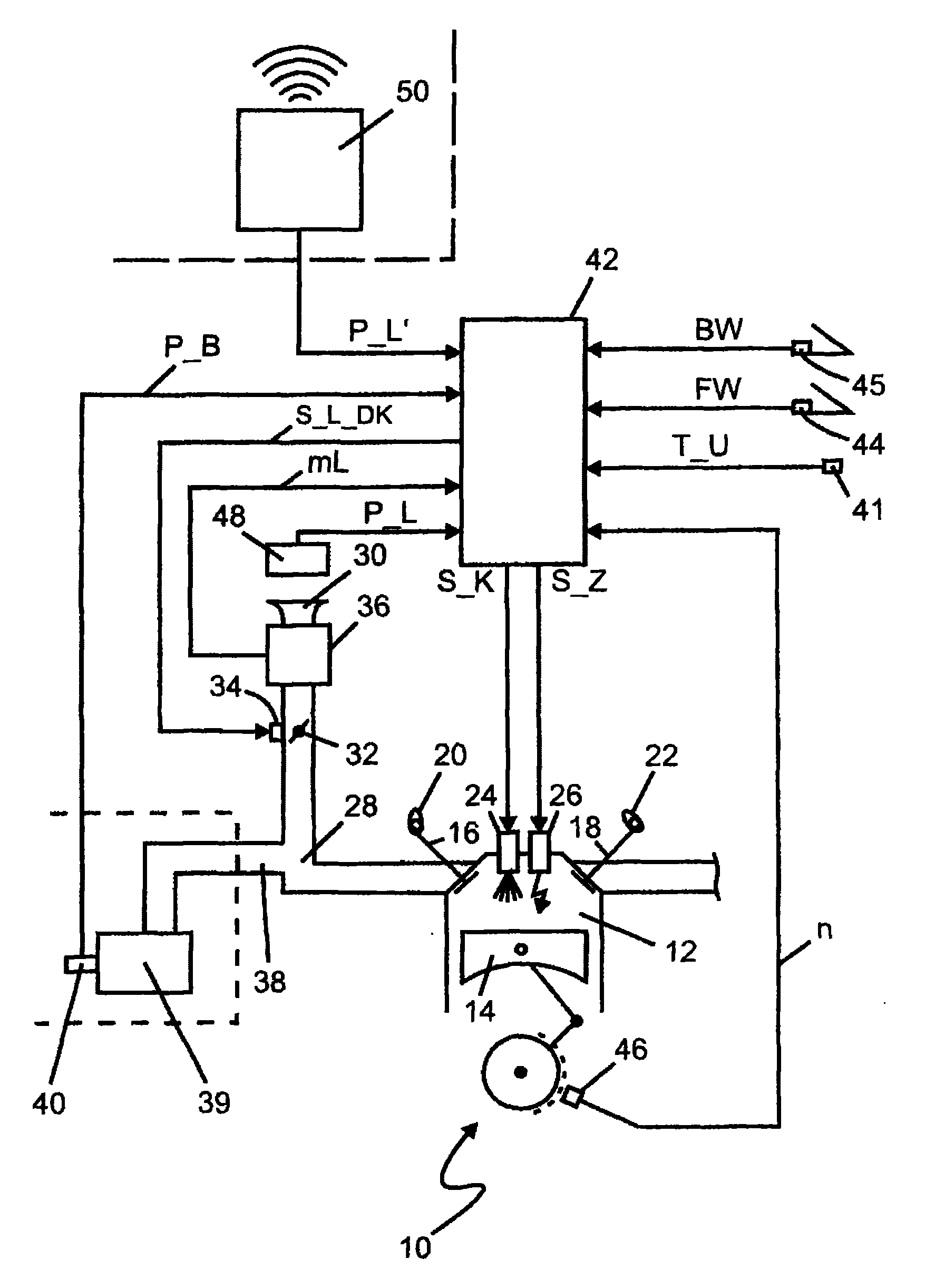

[0017] figure 1 The technical field of the invention is shown. Specifically, figure 1 Shown is an internal combustion engine 10 with a combustion chamber 12 which is movably sealed off by a piston 14 . The change of charge of the combustion chamber 12 is controlled via at least one intake valve 16 and one exhaust valve 18 , which are actuated for this purpose by corresponding actuators 20 , 22 . exist figure 1 In the preferred embodiment, an injector 24 is used to meter the fuel in the air charge into the combustion chamber 22. The resulting fuel and air mixture is ignited by spark plug 26 . The combustion chamber 12 is charged from an intake duct 28 with an intake connection 30 . The intake manifold 28 has a throttle valve 32 , which is operated by a throttle valve adjuster 34 , and an air mass meter 36 . A connecting line 38 branches off from the intake line 28 and leads to a pressure accumulator of a brake booster 39 of the motor vehicle. As an alternative to the ill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com