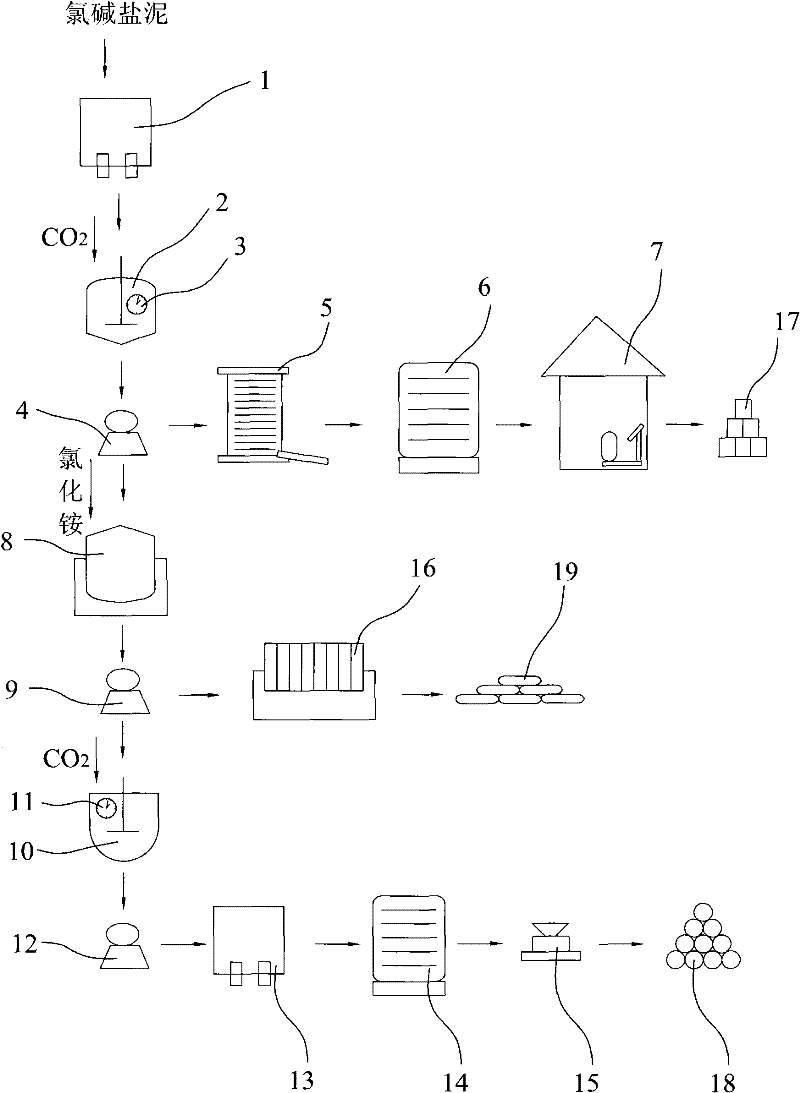

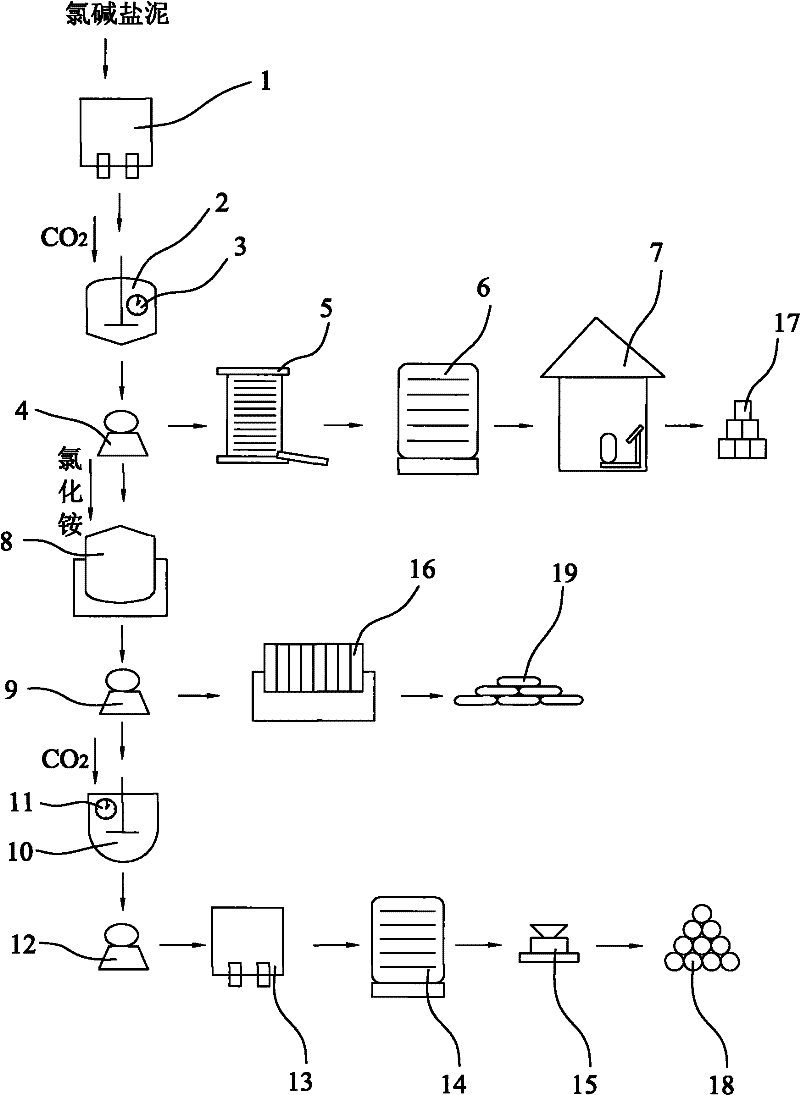

Method for co-production of fine calcium carbonate and sodium silicate, in preparation of light magnesium carbonate by chlor-alkali brine sludge

A technology of light magnesium carbonate and fine calcium carbonate, which is applied in the direction of magnesium carbonate, calcium carbonate/strontium/barium, alkali metal silicate, etc., can solve the problems of non-comprehensive utilization of salt mud, non-utilization and excavation, etc. Achieve the effect of easy operation, simple method and high economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]A method for producing light magnesium carbonate and co-producing fine calcium carbonate and water glass with chlor-alkali salt mud, comprising the steps of washing and filtering 500kg of chlor-alkali salt mud with a washing filter (1) three times to remove soluble acid radical impurities. , the compound containing magnesium oxide, calcium oxide and silicon dioxide as the main components in the salt mud; then, the gained salt mud is put into the first carbonizer (2), and is passed into the first carbonizer (2) Pure carbon dioxide gas makes the magnesium oxide and carbon dioxide contained in the salt mud carbonized according to the mass ratio of pure substance 1:2.0; at this time, magnesium oxide reacts with carbon dioxide and water to produce magnesium bicarbonate or magnesium carbonate, both of which are soluble Calcium oxide reacts with carbon dioxide to produce calcium carbonate, which is basically insoluble in water and thus precipitates; the product obtained by the c...

Embodiment 2

[0040] A method for producing light magnesium carbonate and co-producing fine calcium carbonate and water glass with chlor-alkali salt mud, comprising the steps of washing and filtering 500kg of chlor-alkali salt mud with a washing filter (1) three times to remove soluble acid radical impurities. , the compound containing magnesium oxide, calcium oxide and silicon dioxide as the main components in the salt mud; then, the gained salt mud is put into the first carbonizer (2), and is passed into the first carbonizer (2) The mixed gas containing carbon dioxide gas volume is 25%, so that the magnesia and carbon dioxide contained in the salt mud are carbonized according to the mass ratio of pure substance 1:1.8; at this time, magnesia reacts with carbon dioxide and water to produce magnesium bicarbonate or carbonic acid Magnesium, both of which are soluble in water; calcium oxide reacts with carbon dioxide to produce calcium carbonate, which is basically insoluble in water and thus p...

Embodiment 3

[0042] A method for producing light magnesium carbonate and co-producing fine calcium carbonate and water glass with chlor-alkali salt mud, comprising the steps of washing and filtering 500kg of chlor-alkali salt mud with a washing filter (1) three times to remove soluble acid radical impurities. , containing magnesium oxide, calcium oxide and silicon dioxide as the main components of the compound in the salt mud; then, the gained salt mud is put into the first carbonizer (2), and contains carbon dioxide in the first carbonizer (2) The gas volume is 40% mixed gas, so that the magnesium oxide and carbon dioxide contained in the salt mud are carbonized according to the mass ratio of pure substance 1:2.2; at this time, magnesium oxide reacts with carbon dioxide and water to produce magnesium bicarbonate or magnesium carbonate, Both are soluble in water; calcium oxide reacts with carbon dioxide to produce calcium carbonate, which is basically insoluble in water and thus precipitate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com