Safety brake of elevator tractor

A technology of elevator traction machine and safety brake, which is applied in the direction of hoisting device, etc., to achieve the effect of low energy consumption, low working voltage, vibration and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

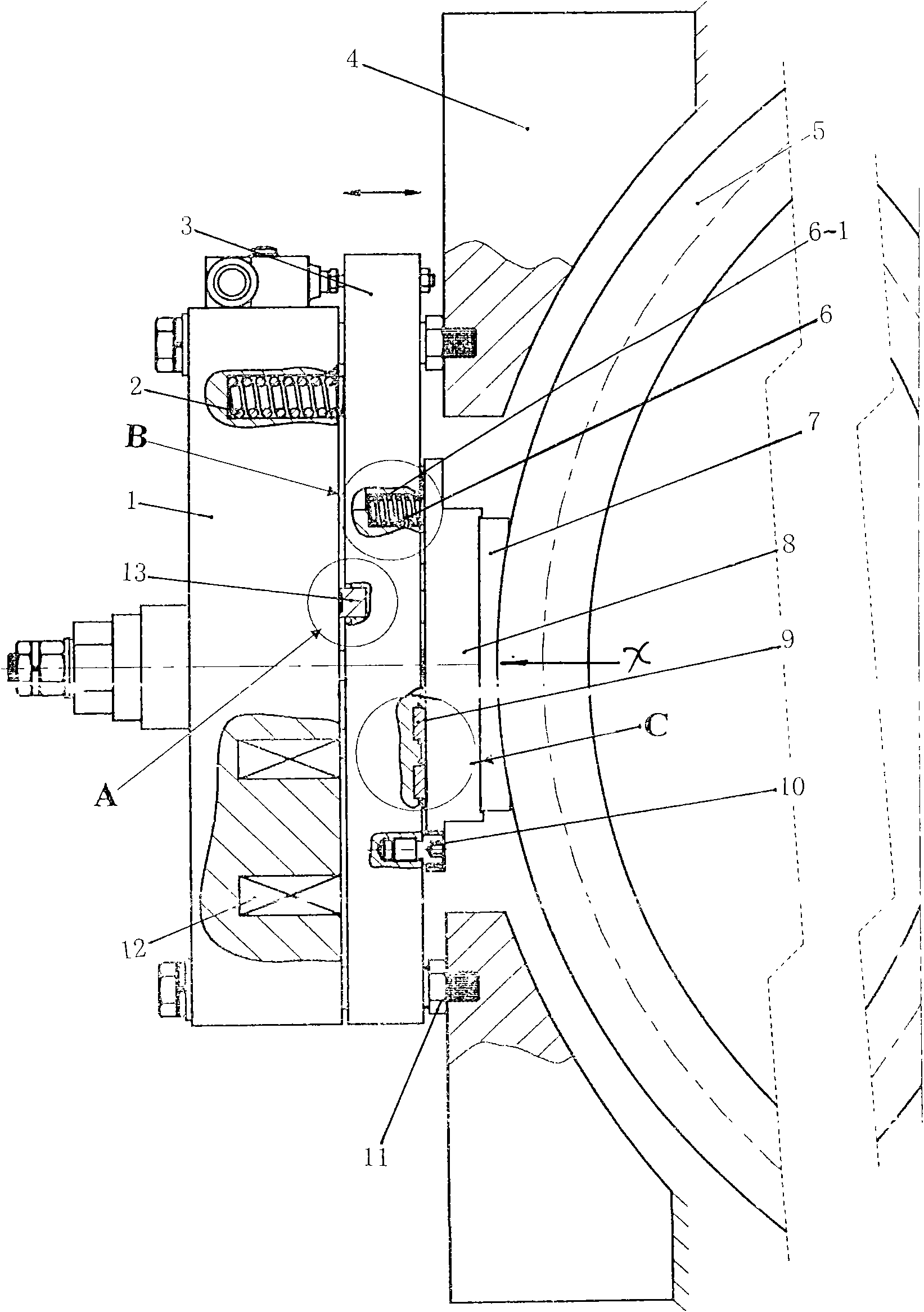

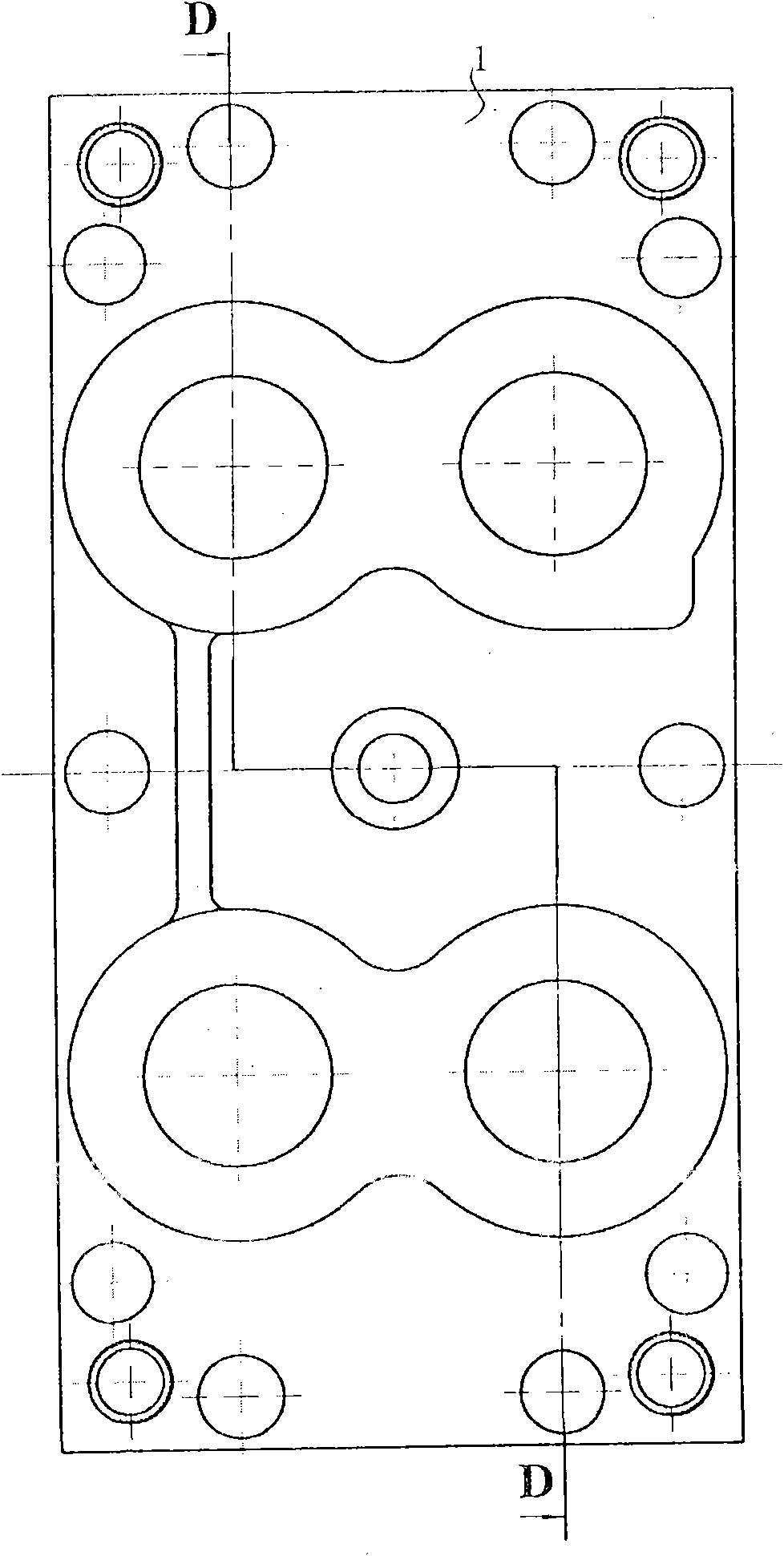

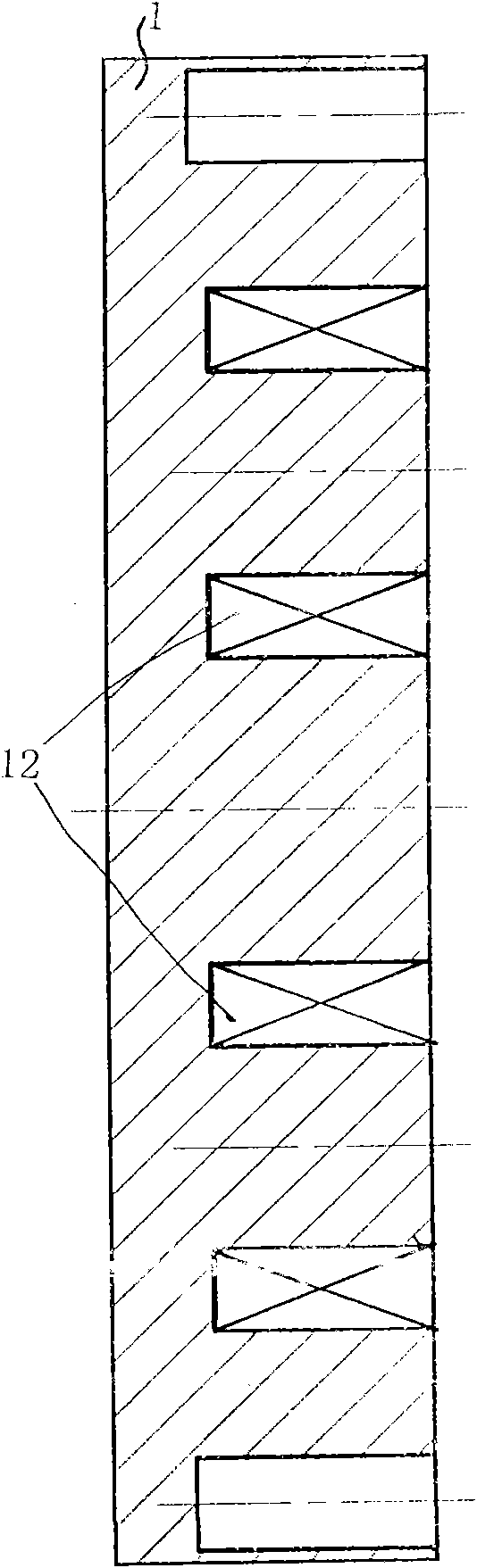

[0038] Figure 1 to Figure 7 Example figures are given. The safety brake of the elevator traction machine in this embodiment includes a grooved disc 1 with a winding coil 12, an armature 3, a compression spring 2 with one end in the spring hole of the grooved disc in contact with one end face of the armature, and a tongue mounted on the other end face of the armature. Plate 8, friction plate 7. Such as figure 2 , image 3 As shown, there are four winding coils on the grooved disk, which are equidistantly distributed on the grooved disk.

[0039] There is an elastic damping pad 13 on the armature relative to the groove plate, and the top of the elastic damping pad stretches out of the armature, and there is a resistance pad 9 on the armature opposite to the tongue plate. The return spring hole 6-1 of the return spring 6 is equipped with the return spring hole 6-1, and the top of the resistance pad extends out of the armature In addition, one end of the return spring is in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com