Heat-pipe wiped-film short-distance distiller

A short-path distillation, heat pipe technology, applied in distillation separation, chemical instruments and methods, separation methods, etc., can solve the problems of uneven heating surface temperature, increased power consumption, coking and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

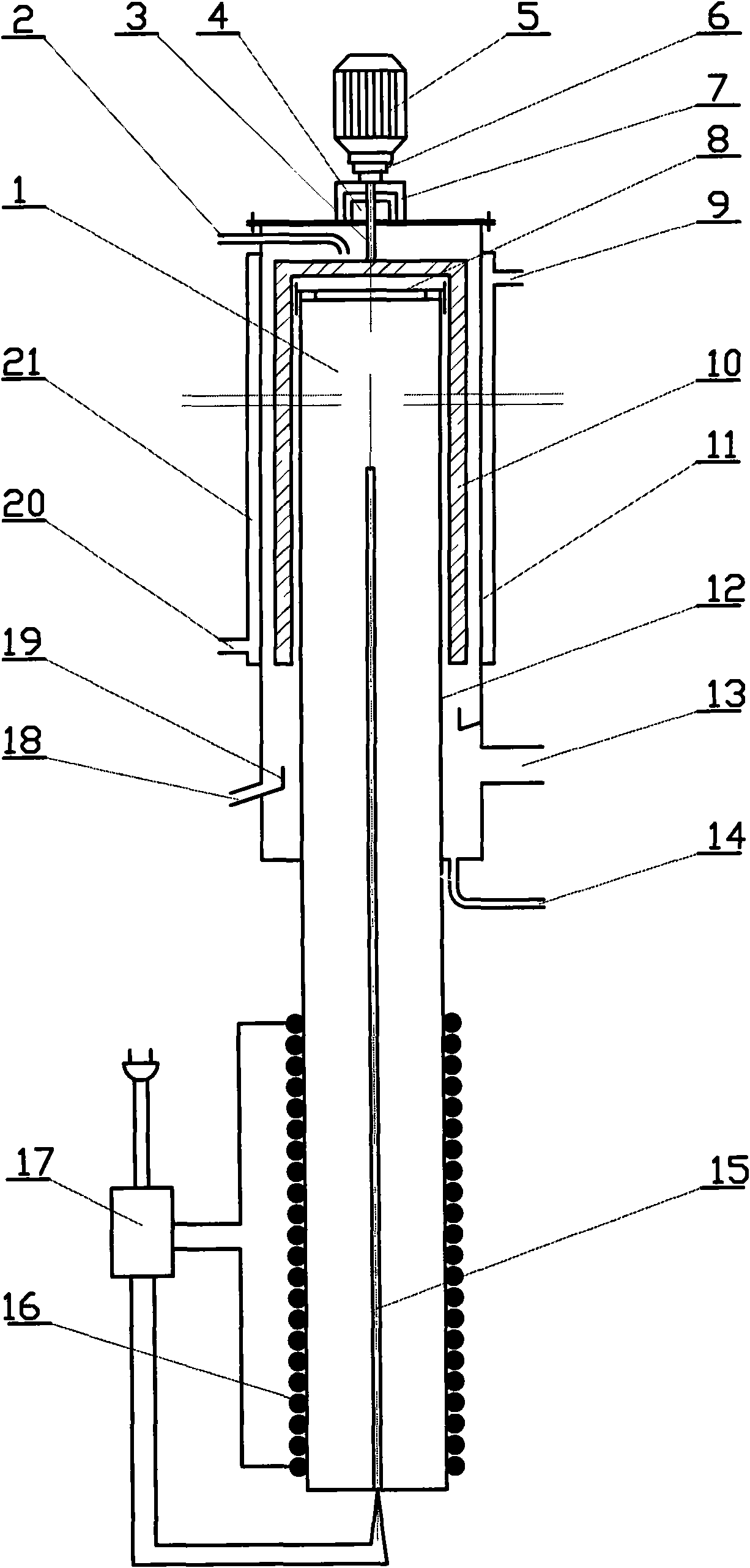

[0011] Attached below figure 1 The present invention is described as follows:

[0012] The heat pipe type scraped film short-path distiller of the present invention is composed of a heat pipe 1, a feed port 2, a rotating shaft 3, a dynamic seal 4, a motor 5, a reducer 6, a frame 7, a feed liquid distributor 8, a cooling medium outlet 9, Scraping film device 10, condensation surface 11, evaporation surface 12, vacuum outlet 13, heavy component outlet 14, thermocouple 15, electric heating element 16, temperature controller 17, light component outlet 18, light component collection tank 19, cooling medium Inlet 20, cooling medium jacket pipe 21 and other components.

[0013] The heat pipe type wiped film short-path distiller of the present invention is arranged vertically. The motor 5 installed on the top is connected with the reducer 6, the reducer 6 is connected with the rotating shaft 3, the rotating shaft 3 passes through the dynamic seal 4 and is connected with the scraping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com