Electric heating bag capable of intelligently realizing explosion-proof control by using singlechip

A single-chip microcomputer and electric heating bag technology, which is applied in computer control, program control, electric heating devices, etc., can solve problems such as electric heating bag damage, safety hazards, arcing, etc., and achieve the effect of improving accuracy and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

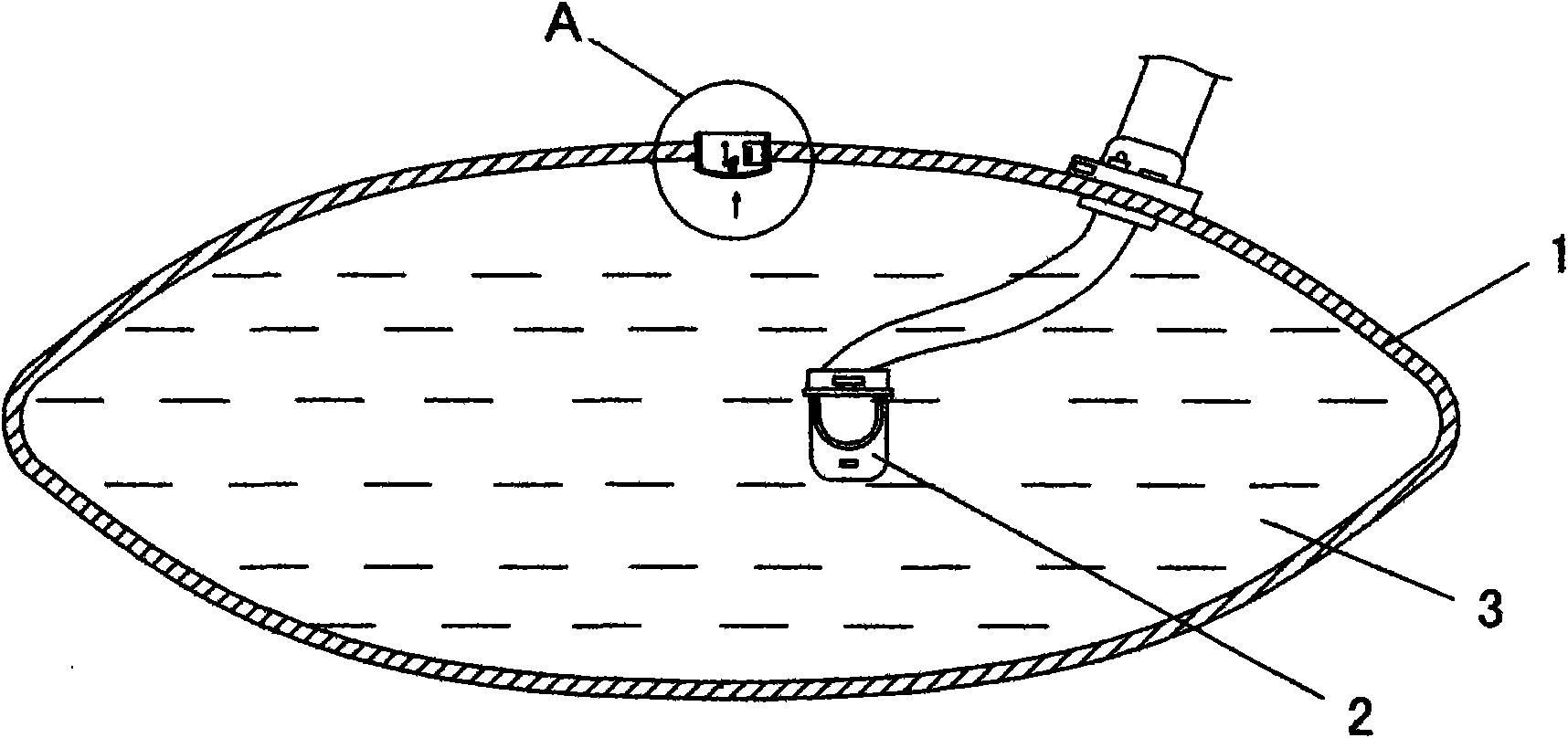

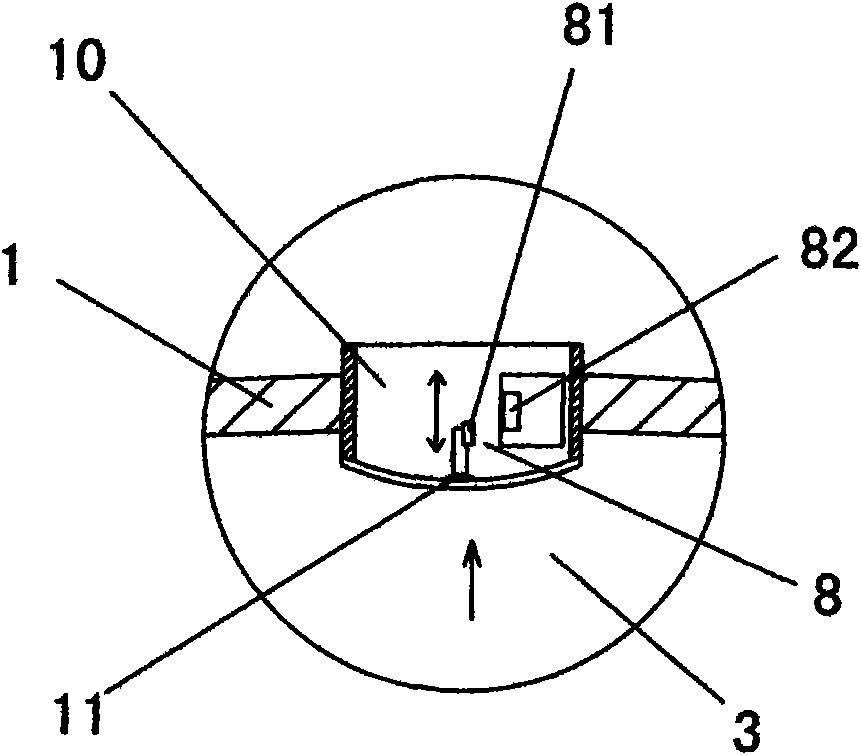

[0033] Embodiment one: if Figure 1 to Figure 3 ,as well as Figure 7 and Figure 8 As shown, a single-chip computer intelligent explosion-proof control electric heating bag includes a bag body 1 and its electric heating body 2. The bag body 1 has a bag cavity 3, and an electric heating body 2 is arranged in the bag cavity 3. The bag body 1 is also provided with a There is a single-chip intelligent explosion-proof control device 4, and the single-chip intelligent explosion-proof control device 4 includes a single-chip microcomputer 5, a step-down current limiting circuit 6, an electric heater control switch 7 and a pressure sensing device 8, and the electric heater control switch 7 can be SCR, the single-chip microcomputer is an MCU processor-SN8P2711, the single-chip microcomputer 5 has at least a power connection terminal 51, a pressure signal detection terminal 52 and a heater control output terminal 53, and the step-down current limiting circuit 6 is connected to the powe...

Embodiment 2

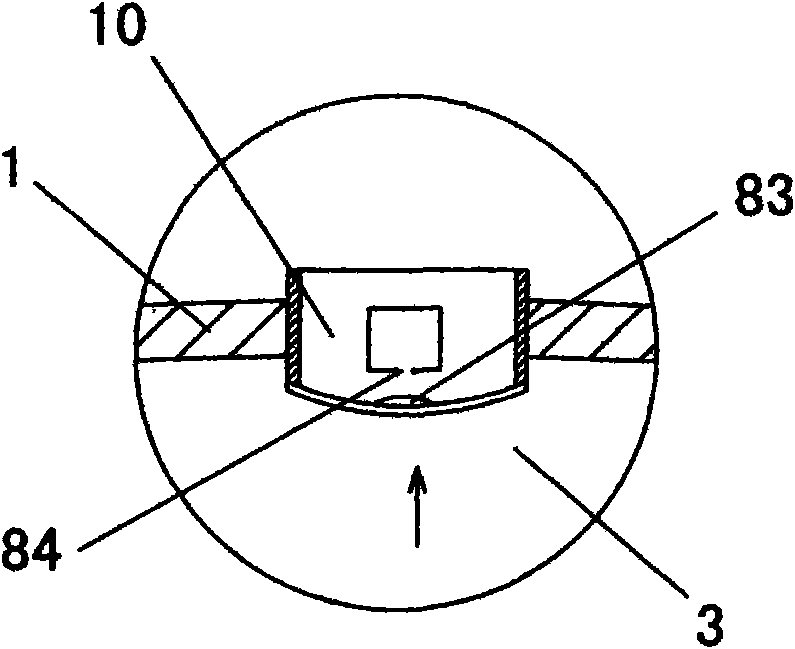

[0038] Embodiment two: if image 3 As shown, it is another embodiment of the pressure sensing device 8 to detect the air pressure in the bag cavity 3. This embodiment is the same as the first embodiment, the only difference is that the pressure sensing device 8 is a conductive silica gel 83 and a PCB circuit Board pressure switch 84, PCB circuit board pressure switch 84 is installed on the sensing device accommodating section 10, and conductive silica gel 83 is arranged on the touch body 11 of sensing device; The touch body 11 of the device is driven and connected to the pressure switch 84 on the PCB circuit board, so that the PCB circuit board is connected, and the single-chip microcomputer 5 obtains an overvoltage signal; on the contrary, if the pressure in the bag cavity 3 is normal pressure, the conductive silica gel 83 leaves the PCB The pressure switch 84 on the circuit board, the pressure switch 84 on the PCB circuit board is disconnected, and the single-chip microcompu...

Embodiment 3

[0039] Embodiment three: as Figure 4 and Figure 5 As shown, it is an embodiment in which the pressure sensing device 8 is used to detect the water pressure in the bag cavity 3 is too high. The sensing device accommodating section 10, the pressure sensing device 8 is installed on the sensing device accommodating section 10, the bag cavity 3 is provided with a pressure sensing device 8 that can be touched by the water pressure of the bag cavity 3 The sensing device touches the floating ball 12 . The touch floating ball 12 of the sensing device and the pressure sensing device 8 are connected by a push rod type or a pull-off type control.

[0040] Working principle: If too much water is injected into the bag cavity 3, the floating ball 12 floats to push and touch the pressure sensing device 8, the single-chip microcomputer 5 obtains an overpressure signal, and turns off the thyristor; on the contrary, if the water filled into the bag cavity 3 is normal , the floating ball 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com