Method for automatically adjusting water volume of water boiler for kitchen stove

A pot of water, water pot technology, applied in household stoves/stoves, lighting and heating equipment, solid heating fuel, etc., can solve the problems of waste, high cost, unsafe battery replacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

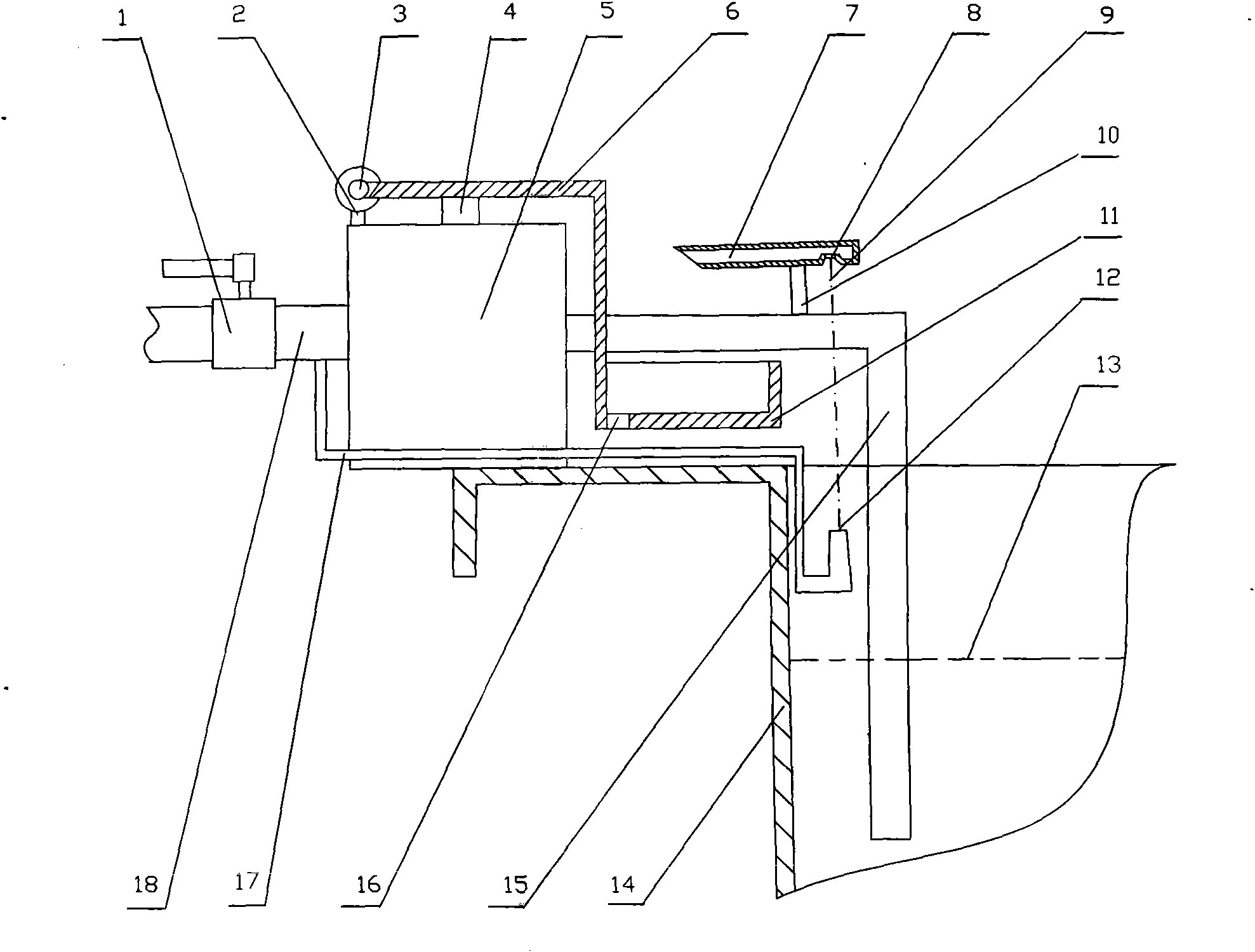

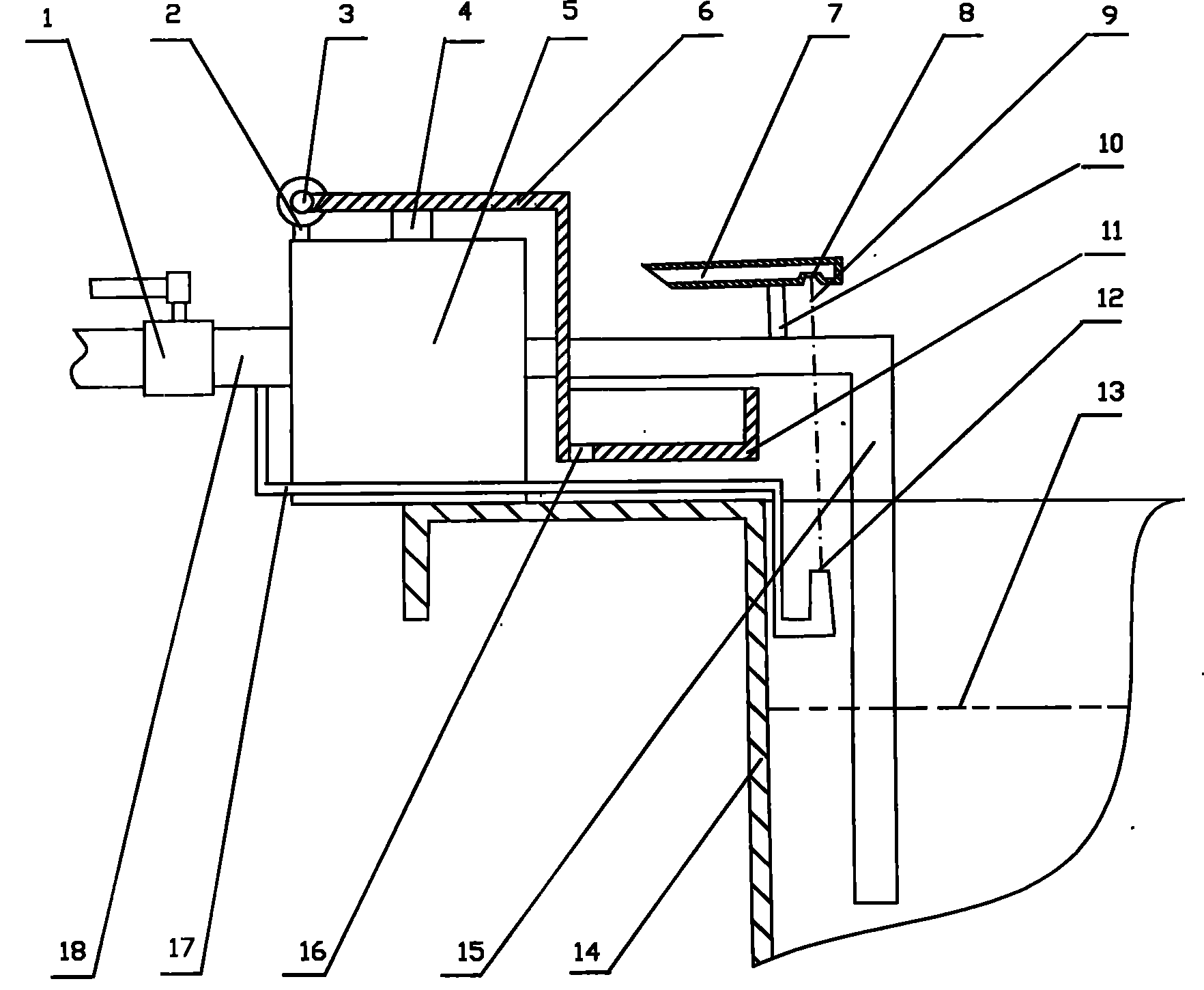

[0007] figure 1 1 is the water inlet faucet, 2 is the movable chain seat, 3 is the movable chain shaft, 4 is the micro valve elastic switch column, 5 is the micro valve, 6 is the water box handle, 7 is the water box drainage device, and 8 is the water tank. The water inlet hole of the box drainage device, 9 is the thin beam water flow, 10 is the water box drainage device bracket, 11 is the water box, 12 is the water outlet of the thin beam jet tube, 13 is the water level line in the water pot, 14 is the water pot, and 15 is the micro Moving valve water outlet pipe, 16 is water box discharge port, and 17 is thin beam jet pipe, and 18 micro-moving valve water inlet pipes. Micro-motion valve 5 among the figure is placed on the outer upper edge place of water pot 14, and movable chain seat 2 is fixed on micro-motion valve 5, and movable chain shaft 3 is arranged on movable chain seat 2. The movable chain shaft 3 and the water box handle 6 are connected together. The water box han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com