Miniature gas turbine combustion chamber

A micro gas turbine, combustion chamber technology, applied in the combustion chamber, continuous combustion chamber, combustion method and other directions, to achieve the effect of small length, simple gas path and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

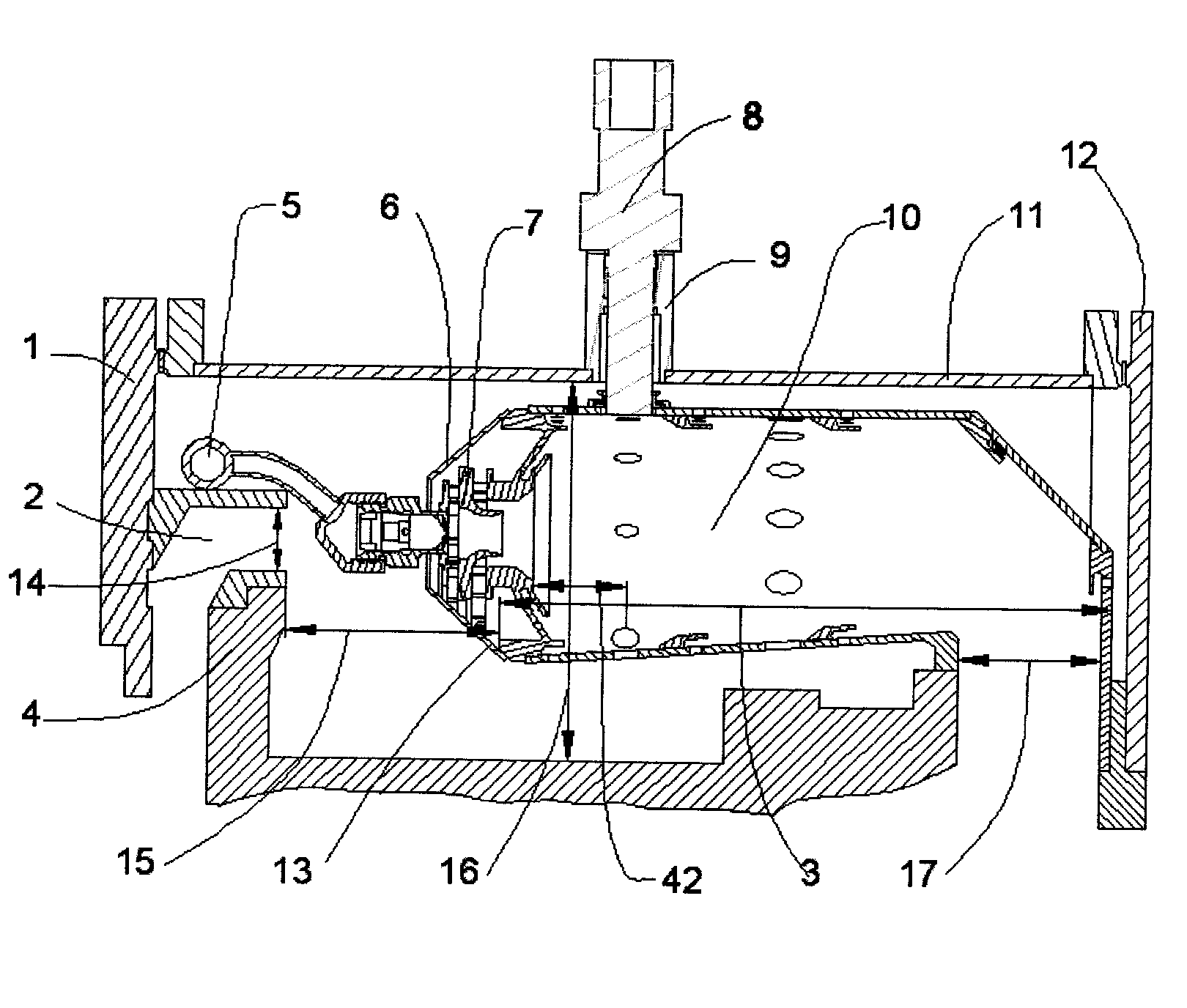

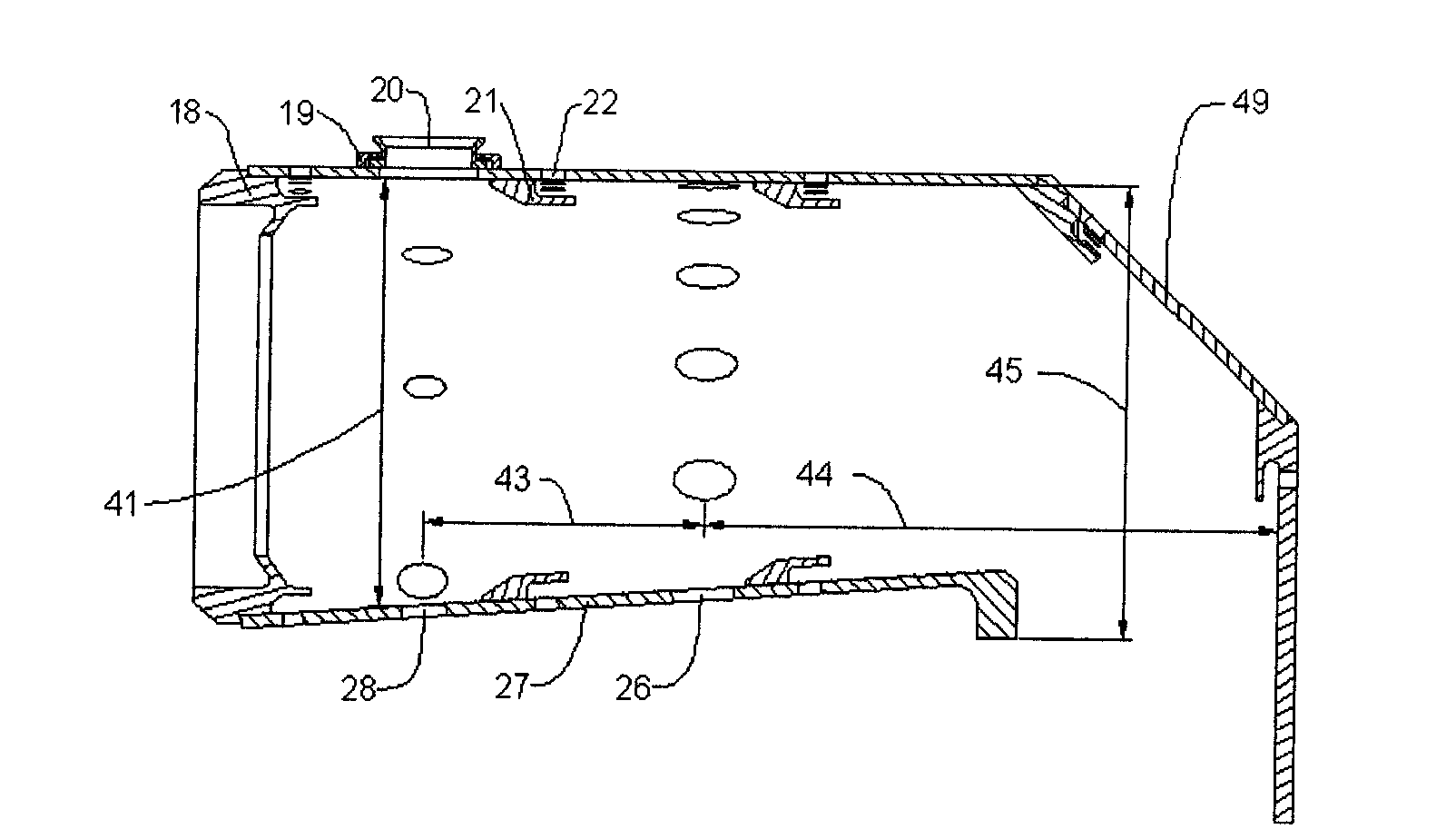

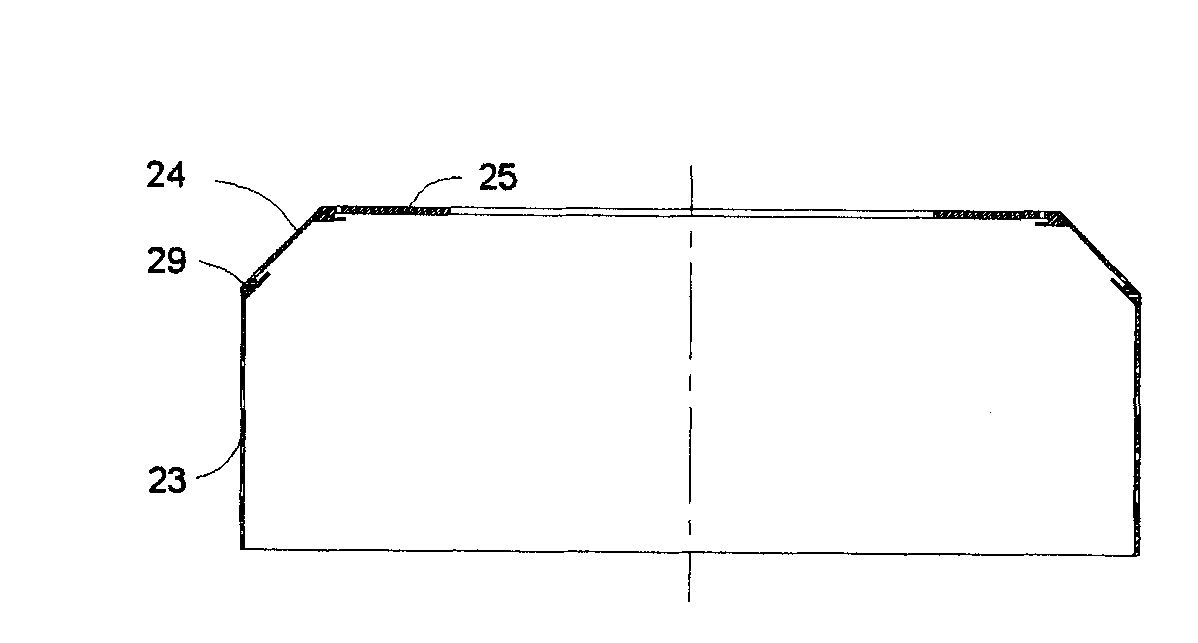

[0030] Such as figure 1As shown, the embodiment of the present invention adopts a ring structure, which is mainly composed of a flame tube 10 , an outer casing 11 , an inner casing 4 , a swirler 7 and a fuel supply system 5 . The flame tube 10 is welded by the outer flame tube 49, the head end wall 18 and the inner flame tube 27, and the distance between the outer flame tube flat section 23 and the inner flame tube 27 is the flame tube height 41. Screw connection is adopted between the vertical section 25 of the outer flame tube and the rear flange 12 of the combustion chamber casing. The rear end of the outer casing 11 is bolted to the rear flange 12 of the casing, and the front flange 1 of the casing is connected to the front end of the casing 11 by bolts. The inlet 2 of the combustion chamber is welded on the front flange 1 of the casing, and is connected with the flow of the centrifugal compressor, and the air enters radially. The spigot fits between the inner casing 4 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com