Antibacterial and bacteriostatic oily ink

An oil-based ink and anti-bacteria technology, applied in the field of printing ink, can solve the problems of destroying ink, ink film, and polluting printed matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation of antibacterial and antibacterial oily ink with garlic volatile oil:

[0046] Material preparation:

[0047] Rosin modified phenolic resin (JC3135 bright resin) 29.Kg

[0048] Linseed oil 15Kg

[0049] Mineral oil D110 28Kg

[0050] Pigment (Organic Pigment Yellow No. 12) 16Kg

[0051] Garlic volatile oil stock solution 0.5Kg

[0052] High-efficiency composite desiccant for offset printing ink (purchased from Beijing Huazhichangye Printing Material Co., Ltd.) 1.5Kg

[0053] White beeswax 3Kg

[0054] 6#Ink oil 7.Kg

[0055] Preparation Process:

[0056] The preparation process of the ink can be divided into three stages: preparation of liquid binder, stirring pre-dispersion and grinding and fine dispersion. The preparation examples of the present invention are as follows:

[0057] In the mixing pot, add 10Kg of linseed oil, mineral oil D110, and JC3135 bright resin in sequence according to the above-mentioned feeding ratio, and heat to 270°C until the materials are dissolv...

Embodiment 2

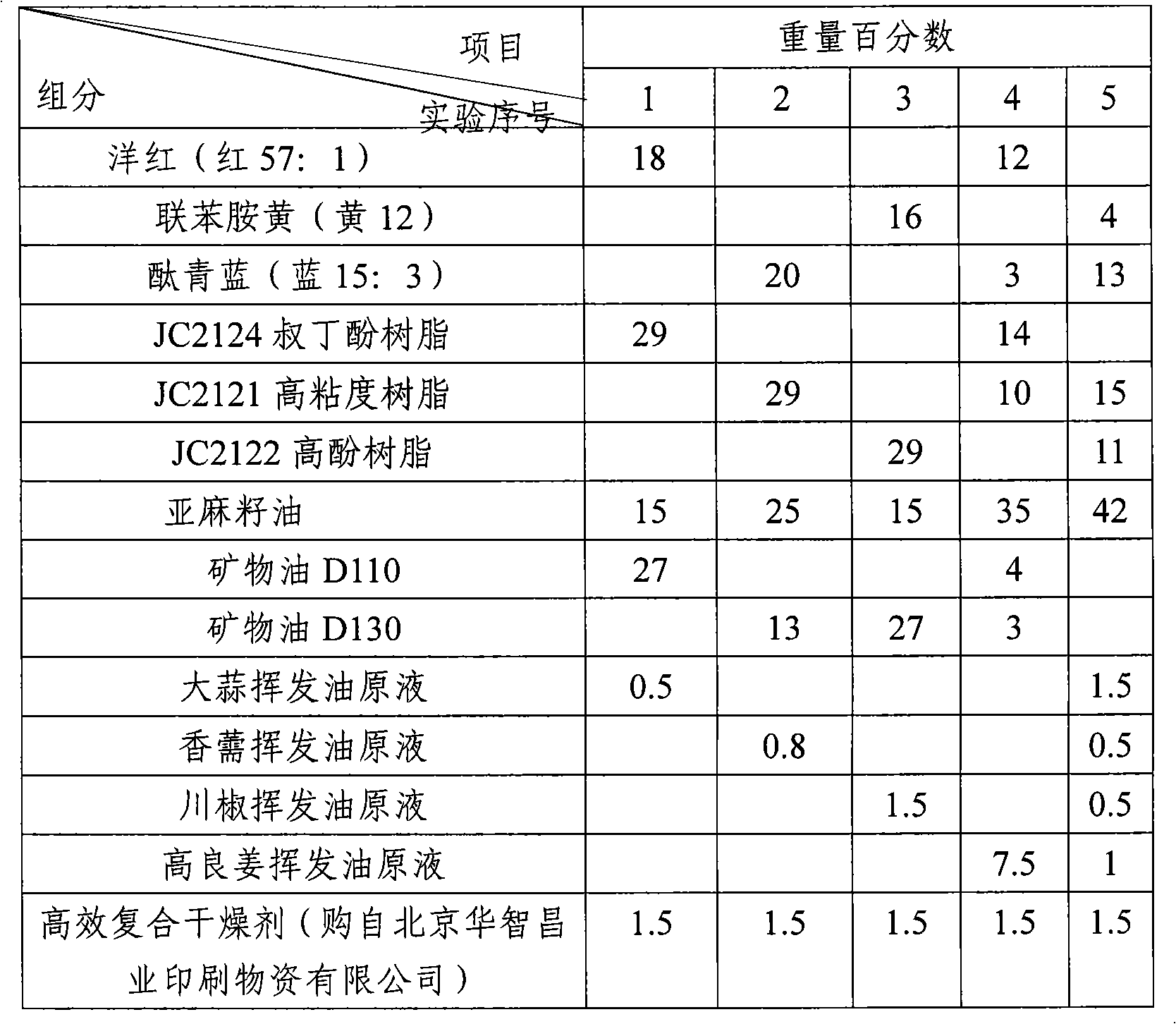

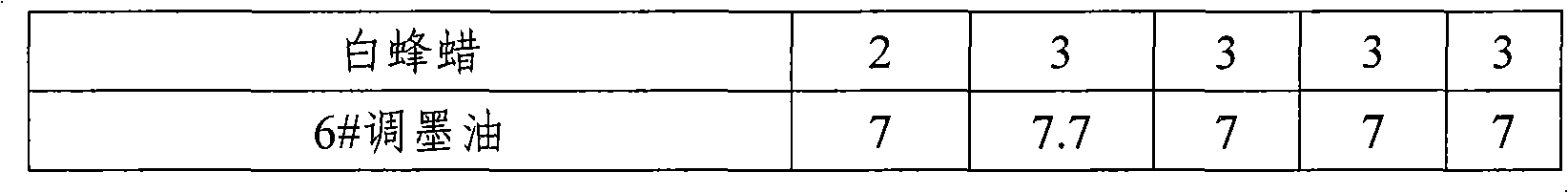

[0062] Ingredients in parts by weight of each component shown in Table 1:

[0063] Table 1 Composition of oil-based ink

[0064]

[0065]

[0066] Referring to the preparation process of Example 1 above, an oil-based ink was prepared.

[0067] On the self-adhesive label offset press, use antibacterial and antibacterial oily ink printing, the printing size is 310mm×254mm, the paper roll width is 100mm, and the printing speed is 50m / min. The printing process is stable and easy to operate. The printed products are exquisite and have good antibacterial effect. After testing, the diameter of the antibacterial (E. coli) circle is 5mm, 5mm, 10mm, 8.9mm.

Embodiment 3

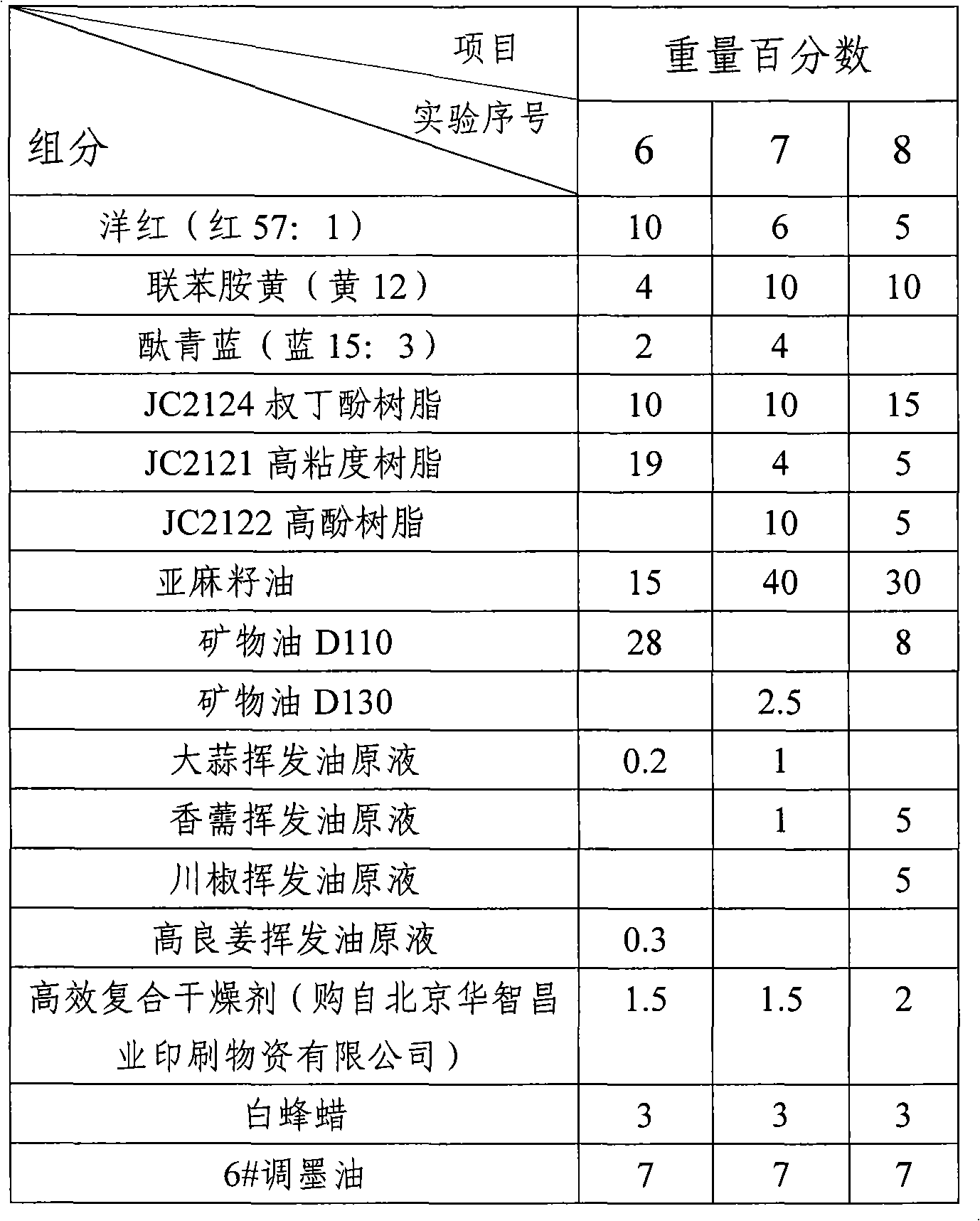

[0069] Ingredients according to the weight percentage of each component shown in Table 2:

[0070] Table 2 Composition of oil-based ink

[0071]

[0072] Preparation Process:

[0073] Referring to the preparation process of Example 1 above, an oil-based ink was prepared.

[0074] On the self-adhesive label offset press, use antibacterial and antibacterial oily ink printing, the printing size is 310mm × 254mm, the paper roll width is 330mm, and the printing speed is 50 m / min. The printing process is stable and easy to operate. The printed products are exquisite and have good antibacterial effect. After testing, the diameter of the antibacterial (E. coli) circle is 3mm, 5mm, and 10mm respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com