Bismuthyl carbonate micro flowery material with graded structure and preparation method thereof

A technology of bismuth oxycarbonate and micro-flowers is applied in chemical instruments and methods, bismuth compounds, inorganic chemistry, etc., to achieve the effects of short time consumption, low cost and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

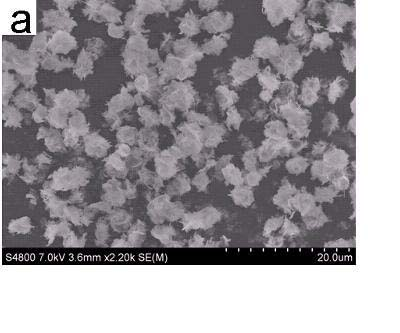

[0021] Preparation of bismuth oxycarbonate microflower material with hierarchical structure:

[0022] (1) Dissolve 3.88g of bismuth nitrate in 1M dilute nitric acid (20mL), and then add it dropwise to excess sodium carbonate solution. The molar ratio of bismuth nitrate to sodium carbonate is 1:3, resulting in a large amount of white precipitate. After magnetic stirring for 30 minutes, it was kept at 60° C. for 12 hours.

[0023] (2) Wash and filter with deionized water and ethanol respectively, and then dry at 60°C for 6 hours to obtain Bi 2 o 2 CO 3 Material.

Embodiment 2

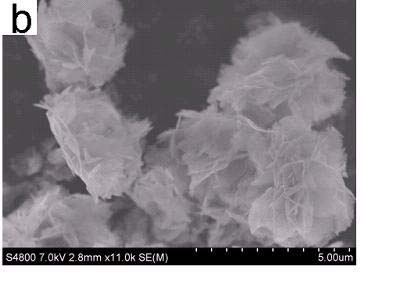

[0025] Preparation of bismuth oxycarbonate microflower material with hierarchical structure:

[0026] (1) Dissolve 3.88g of bismuth nitrate in 1M dilute nitric acid (20mL) first, and then add it dropwise to excess sodium carbonate solution. The molar ratio of bismuth nitrate to sodium carbonate is 1:6, resulting in a large amount of white precipitate. After magnetic stirring for 30 minutes, it was kept at 60° C. for 12 hours.

[0027] (2) Wash and filter with deionized water and ethanol respectively, and then dry at 60°C for 6 hours to obtain Bi 2 o 2 CO 3 Material.

Embodiment 3

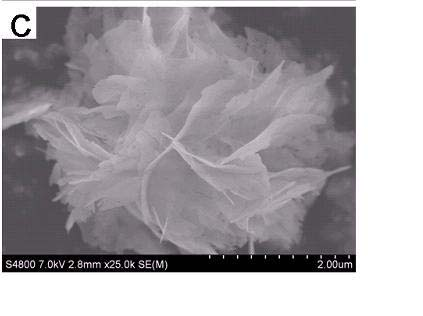

[0029] Preparation of bismuth oxycarbonate microflower material with hierarchical structure:

[0030] (1) Dissolve 3.88g of bismuth nitrate in 1M dilute nitric acid (20mL), and then add it dropwise to excess sodium carbonate solution. The molar ratio of bismuth nitrate to sodium carbonate is 1:9, resulting in a large amount of white precipitate. After magnetic stirring for 30 minutes, it was kept at 60° C. for 12 hours.

[0031] (2) Wash and filter with deionized water and ethanol respectively, and then dry at 60°C for 6 hours to obtain Bi 2 o 2 CO 3 Material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com