Core rod for drawing pipe

A technology for drawing pipes and mandrels, applied in the field of mandrels for drawing pipes, can solve the problems of large deviation of the inner holes of drawn pipes, shaking of pipes, affecting the quality of drawn pipes, etc., and achieve the effect of good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

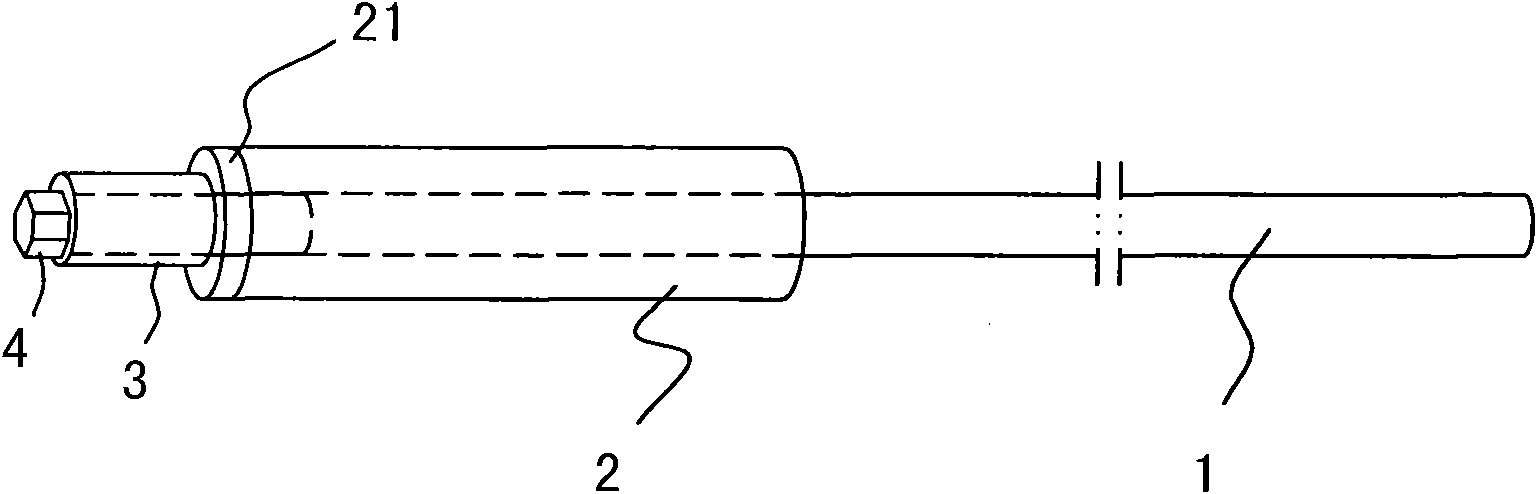

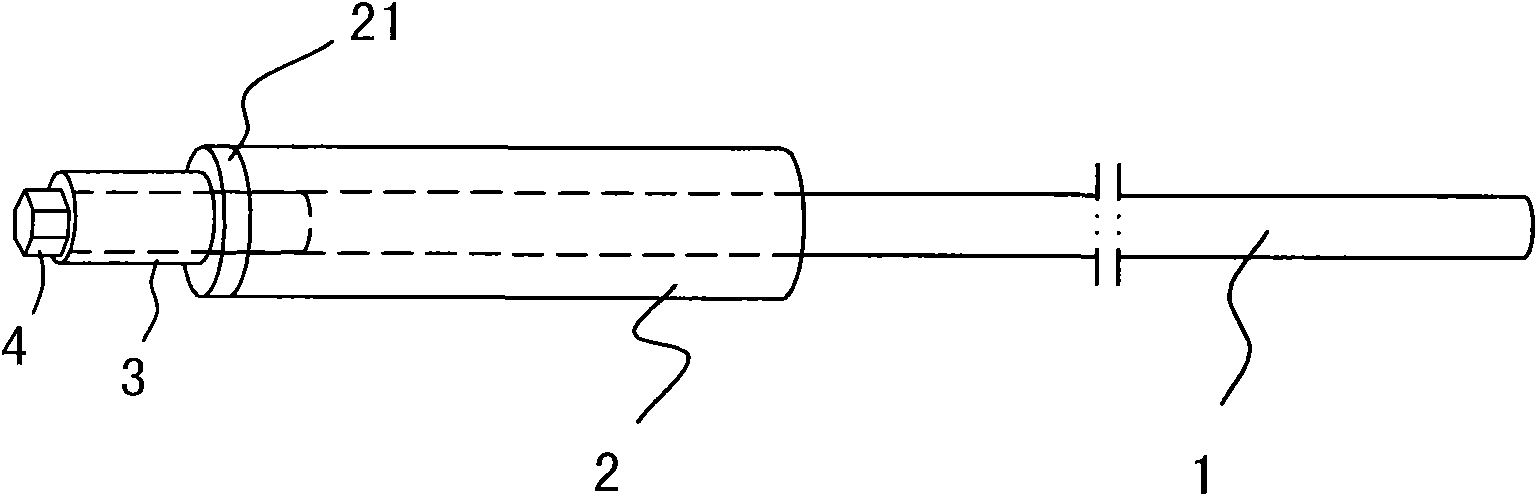

[0010] see figure 1 , the mandrel body 1 is a solid column rod, and its right end is a fixed push end. A sleeve 2 is arranged around the front end (ie, the left end) of the mandrel body 1 , and a threaded counterbore is arranged on the left end surface of the mandrel body 1 , and the function of the threaded counterbore is to receive the fixing bolt 4 . The end surface of the left end of the casing 2 is welded with a sealing piece 21. There is a through hole in the middle of the sealing piece 21. The aperture of the through hole is smaller than the outer diameter of the mandrel body 1. The casing 2 is positioned. The end surface of the right end of the sleeve 2 is welded to the mandrel body 1, which can ensure that the sleeve 2 and the mandrel body 1 are tightly fixed.

[0011] As another embodiment, the inner hole wall of the sleeve 2 can closely match the outer wall of the mandrel body 1 .

[0012] A large number of experiments have proved that the length of the casing 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com