Adjustable mud-scraping gear structure for rod-toothed crusher

A technology of crusher and toothed roller, applied in grain processing and other directions, can solve the problems of cumbersome production and maintenance, small reserved space at the bottom, inconvenience, etc., and achieve the effects of simple production and maintenance, easy processing and manufacturing, and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

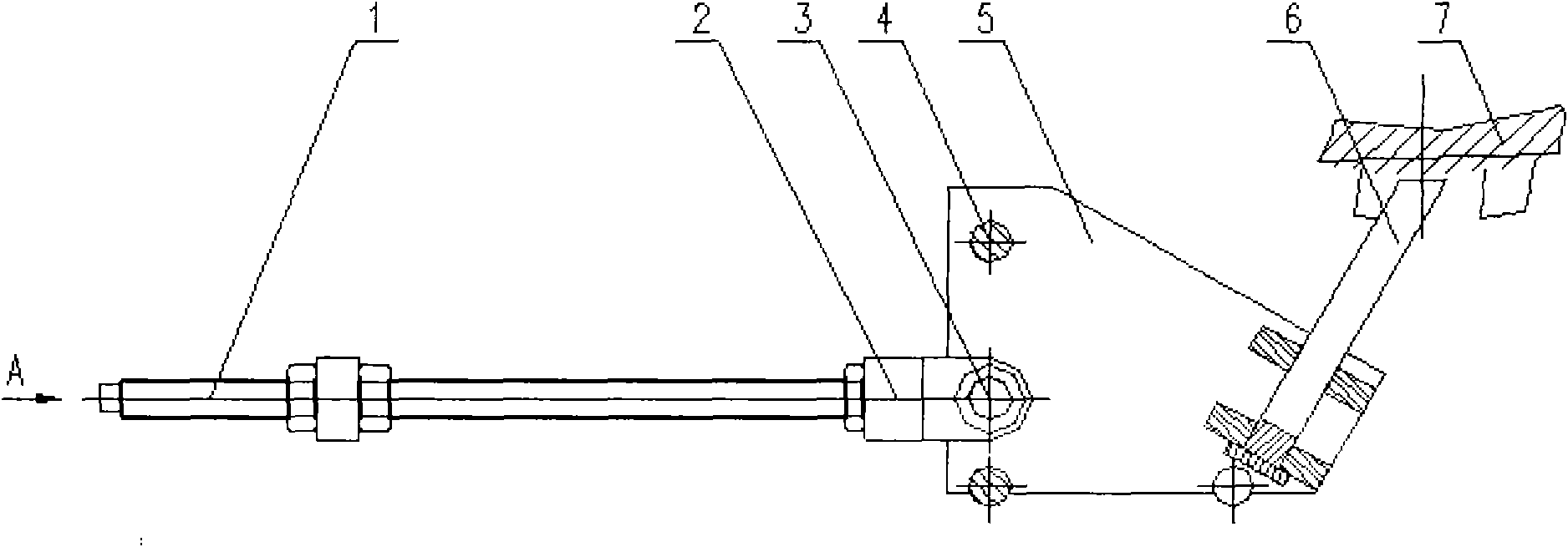

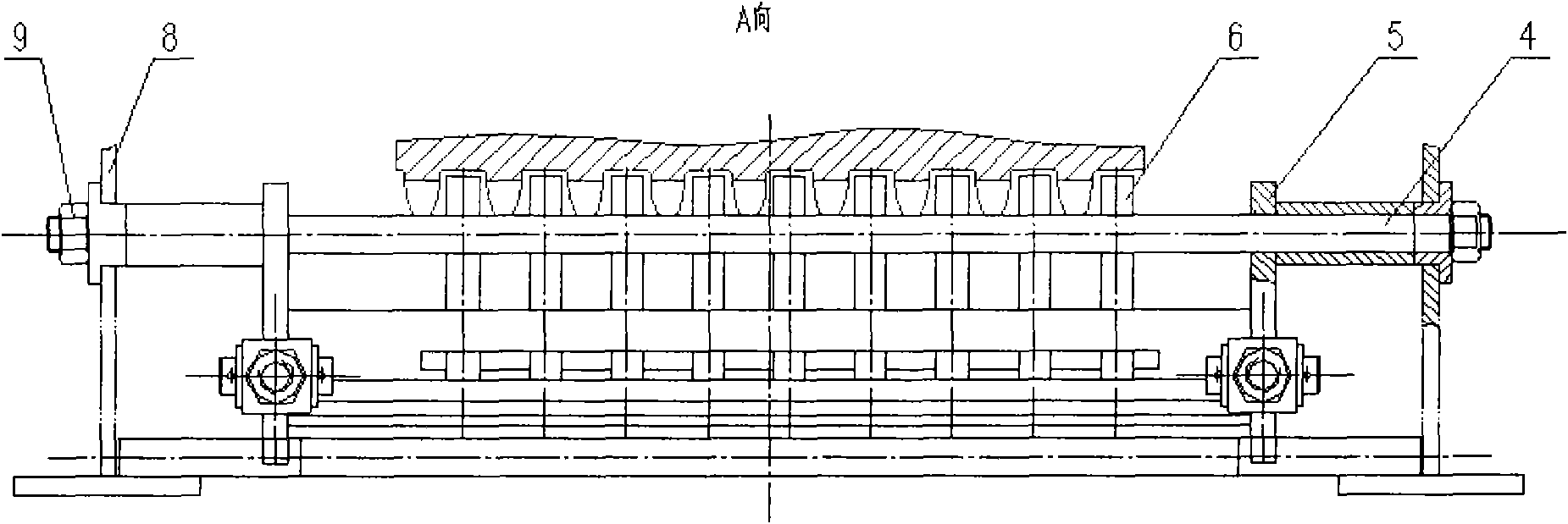

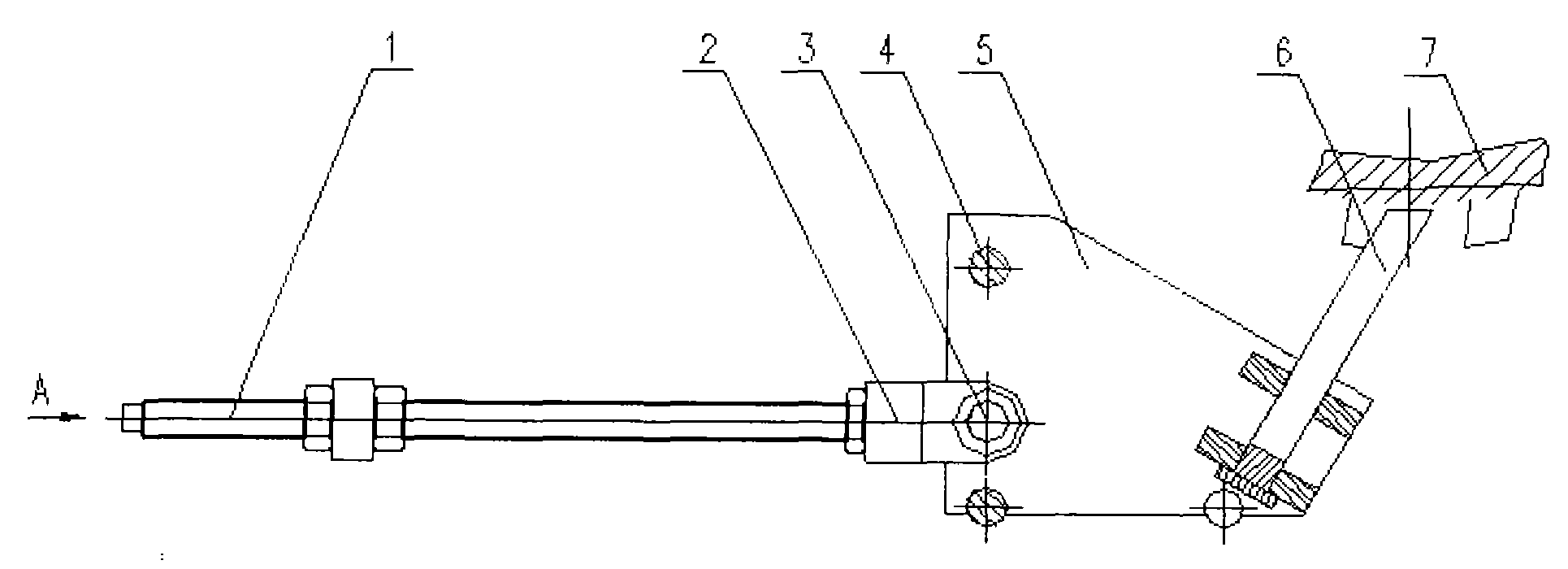

[0012] see figure 1 and figure 2 In the figure, the roller skin 7 and the shell 8 are parts associated with the mud-removing tooth structure on the toothed roller crusher. First, the beam shaft 4 is installed on the cage 5 with a row of mud-removing teeth 6 fixed. After the two ends of the beam shaft 4 are installed with the cage 5, they are installed with the shell 8 of the crusher and fixed on the shell by nuts 9. On the body 8, the cage 5 can rotate around the beam shaft 4; the bottom of the cage 5 is connected with the eye nut 2 through the pin shaft 3, and the eye nut 2 is connected with the adjusting screw 1 by threads. Screw in the adjusting screw 1, through the transmission of the ring nut 2 and the pin shaft 3, push the cage 5 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com