Method for pre-expanding cold-shrinking cable accessory

A technology of cable accessories and expansion cones, which is applied in the field of pre-expansion of cold-shrinkable cable accessories, can solve the problems of affecting processing efficiency, long processing cycle, and high cost of steel bars, so as to improve operating efficiency, improve product quality, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

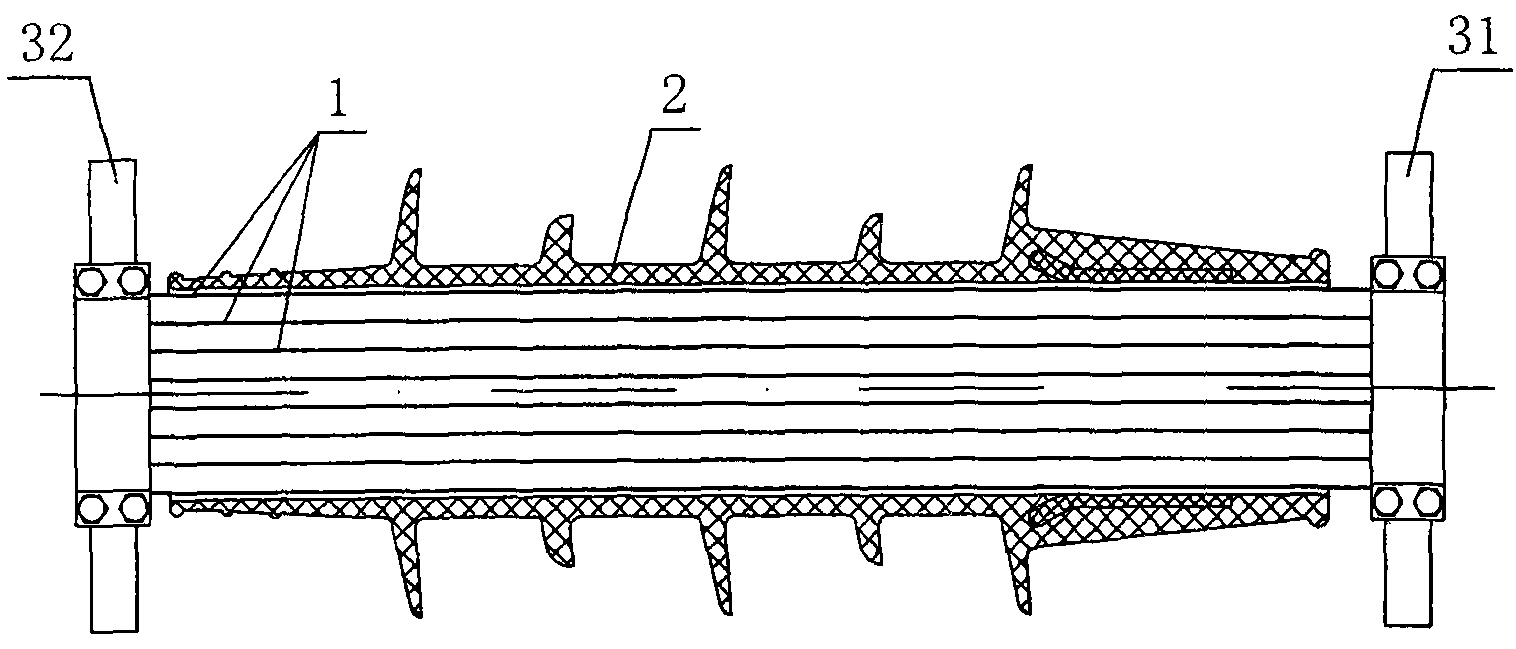

[0017] Refer to Figures 1 to 3. The pre-expansion method of cold-shrinkable cable accessories provided by the present invention comprises the following steps:

[0018] a) Pass a plurality of steel wires 1 through the cold-shrinkable cable accessories 2 to be expanded, and use the expansion disks 31 and 32 pre-installed on the first and second stations of the workbench to respectively clamp the two ends of the steel wires 1;

[0019] b) synchronously expand the openings of the expansion disks 31 and 32 and tighten all the steel wires 1, and use the steel wires 1 to expand the cold-shrinkable cable accessories 2 (see Figure 1);

[0020] c) According to the size of the cold-shrinkable cable accessory 2, select an expansion rod 4 with an expansion cone 41 at one end, and place the support tube 5 on the expansion rod at the rear of the expansion cone 41, and opposite to the expansion cone 41 The other end of the expansion rod 4 is sleeved with an end cap 6, and the support tube 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com