Microscopy CT imaging device with three-free degree motion control and correcting method thereof

A technology of motion control and CT imaging, applied in the direction of non-electric variable control, position/direction control, control/adjustment system, etc., can solve the problems of large error, serious motion jitter, low precision, etc., and achieve uniform speed and good radiation shielding effect, high-precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to describe the technical solution of the above-mentioned invention in more detail, the inventor cites specific examples below to illustrate the effect; it should be emphasized that these examples are used to illustrate the present invention and not limit the scope of the present invention.

[0036] include

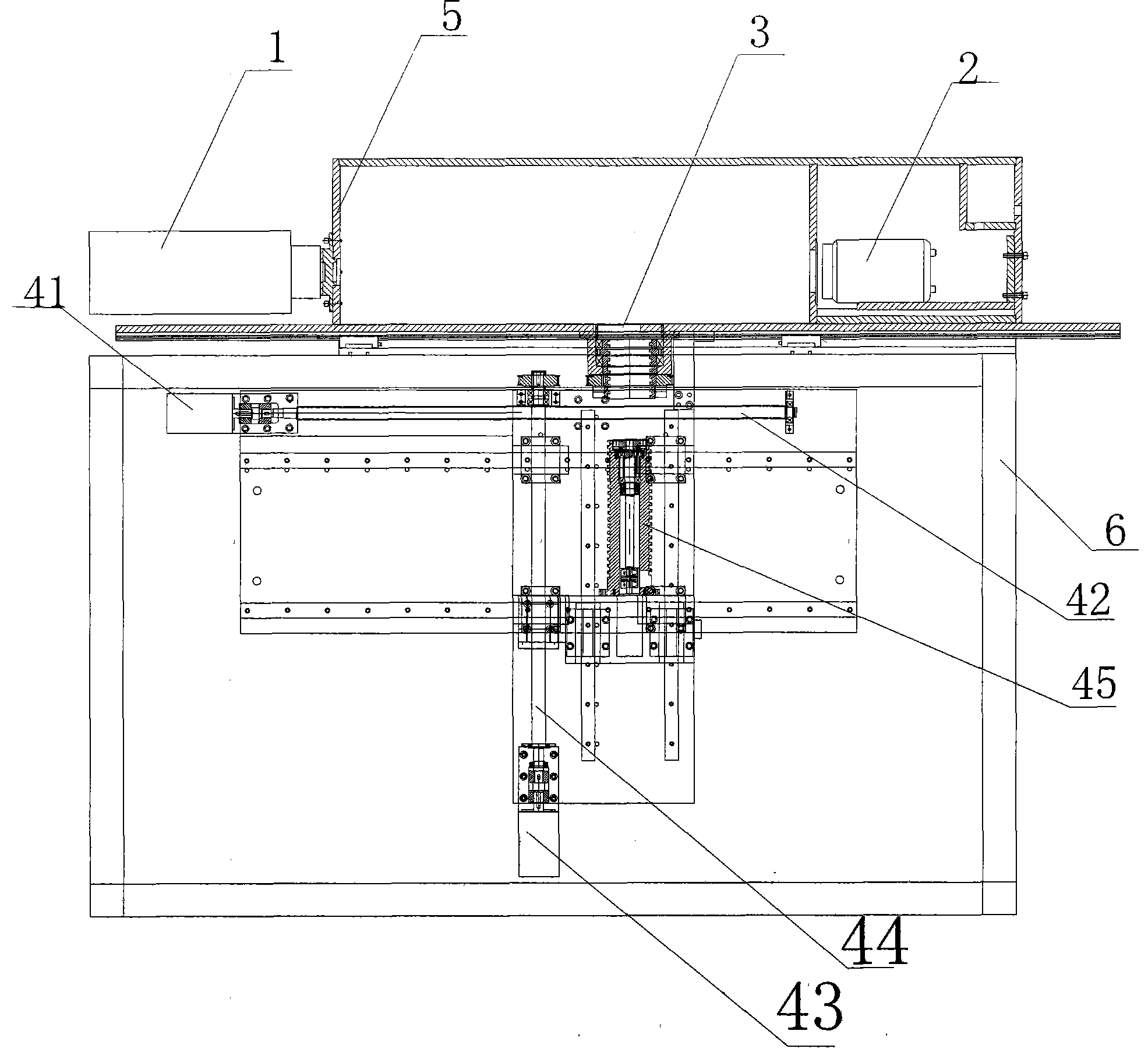

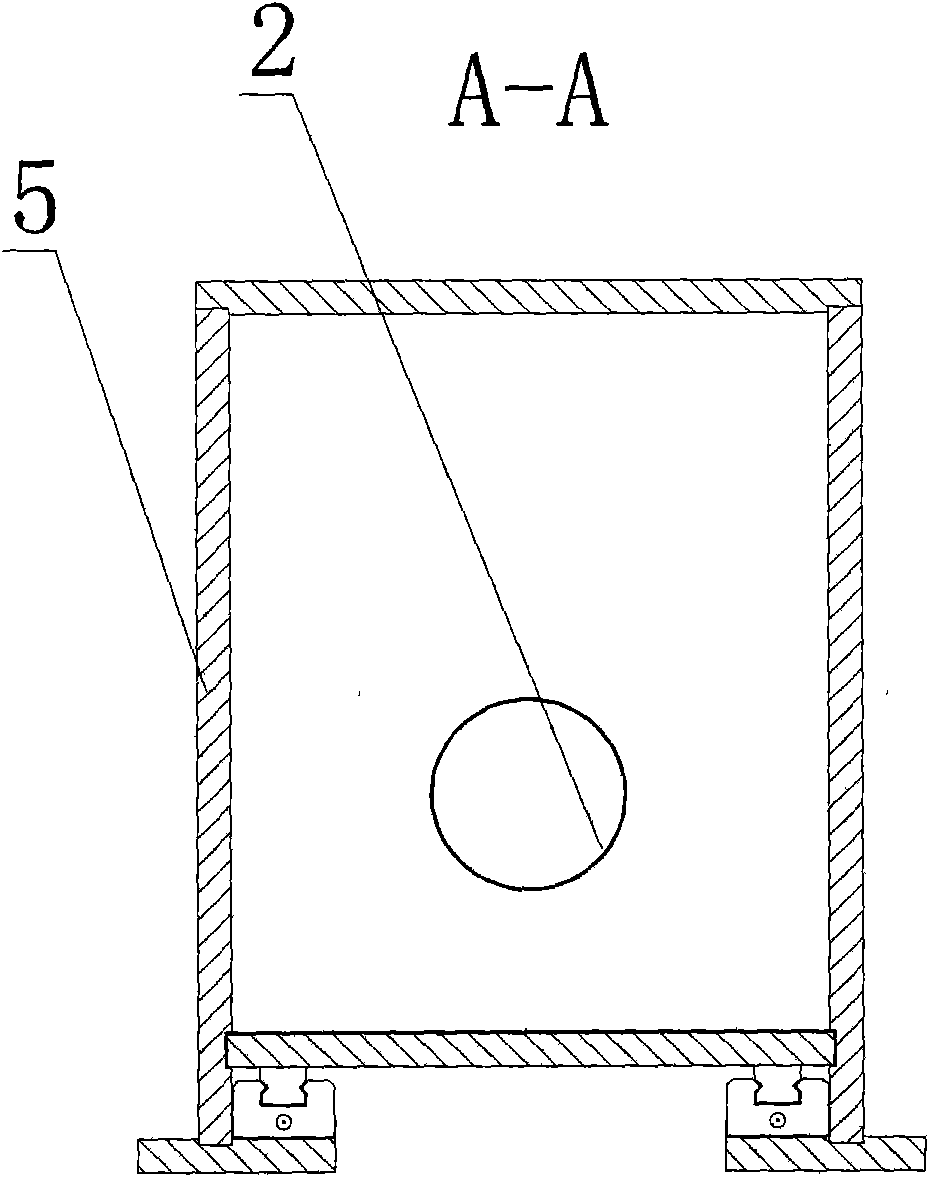

[0037] Embodiments are shown in Figures 1 to 5, the micro-CT imaging device with three-degree-of-freedom motion control includes an X-ray source 1, an X-ray detector 2, and a sealed box 5 for installing the X-ray source and X-ray detection The sealing box of the device, the system skeleton, the cabinet door, the safety shielding device, the external frame, etc.; the stage 3 is set between the X-ray source 1 and the X-ray detector 2, and the drive stage is set on the outside of the stage. Driving device for horizontal, vertical and rotational movement. The X-ray detector 2 is arranged in the sealed box, and forms a closed chamber with the X-ray source 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com