Manufacturing method of heat pipe

A manufacturing method and technology of heat pipes, which are applied to tubular elements, heat exchange equipment, indirect heat exchangers, etc., can solve problems such as unfavorable observation and monitoring of heat pipes, opaque shells, etc., and achieve the effect of enhancing excellent heat transfer performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the embodiments with reference to the accompanying drawings.

[0011] Normally, the heat pipe generally includes a sealed shell in which a working fluid is encapsulated and capillary structures are provided on the inner wall or cavity of the shell. The overall shape of the heat pipe mainly has a plate shape (flat shape) or a tube shape. In this embodiment, a tube heat pipe is taken as an example for illustration, but the present invention is not limited to the scope of the tube heat pipe.

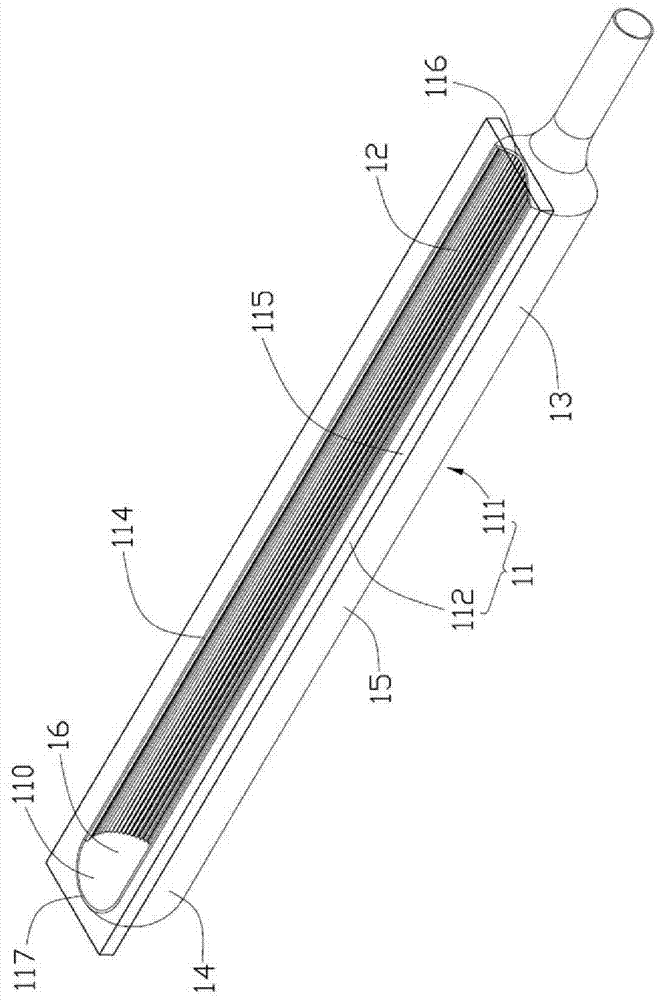

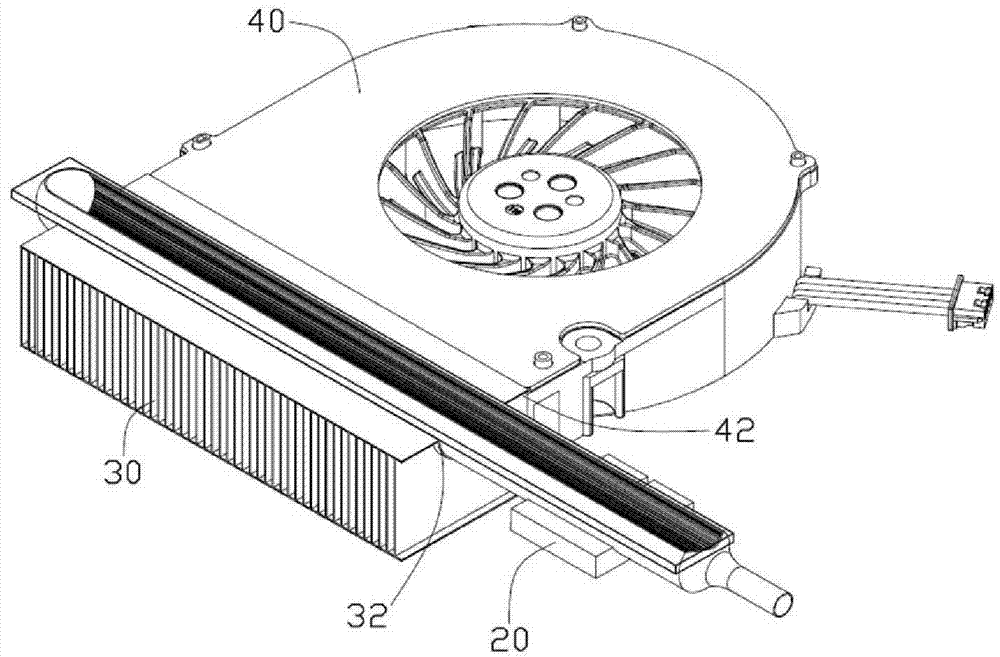

[0012] Such as figure 1 As shown, the heat pipe 10 includes a closed casing 11 , a capillary structure 12 disposed in the casing 11 , and an appropriate amount of working fluid (not shown) filled in the casing 11 . The heat pipe 10 includes an evaporating section 13 and a condensing section 14 respectively located at two ends of the housing 11 , and an adiabatic section 15 connected between the evaporating sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com