Liquid heating device, core of the said device and a fabricating method thereof

A technology of heating device and manufacturing method, which is applied to fluid heaters, water heaters, lighting and heating equipment, etc., can solve the problems of circuit damage, easy formation of cracks, and easy destruction, etc., achieve high heat transfer coefficient, promote liquid heating, Save the effect of electronic temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

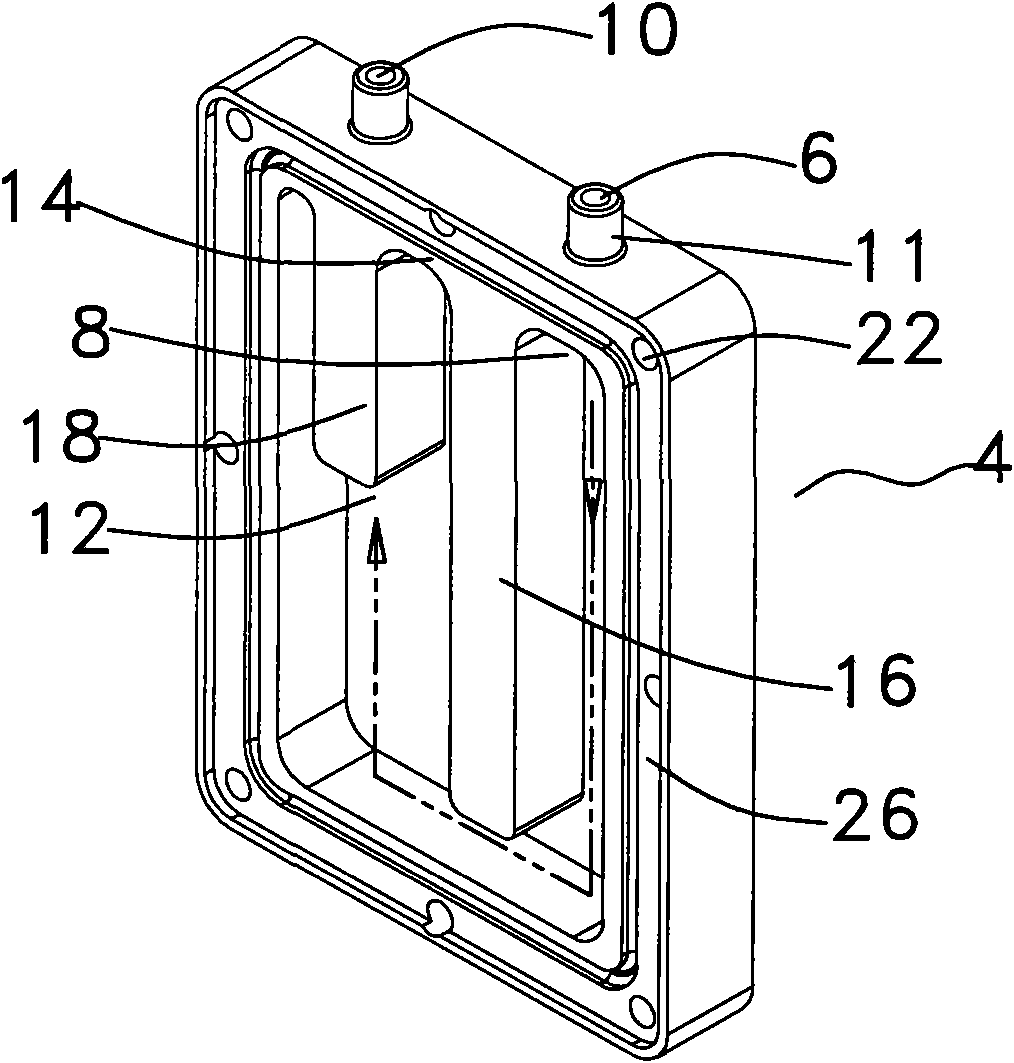

[0051] attached Figure 1 to Figure 6 , is a specific embodiment of a liquid heating device (such as a drinking water heating device). as attached figure 1 The liquid heating device is generally designated 2 as shown. The top of the liquid heating device 2 is provided with two joints 11 .

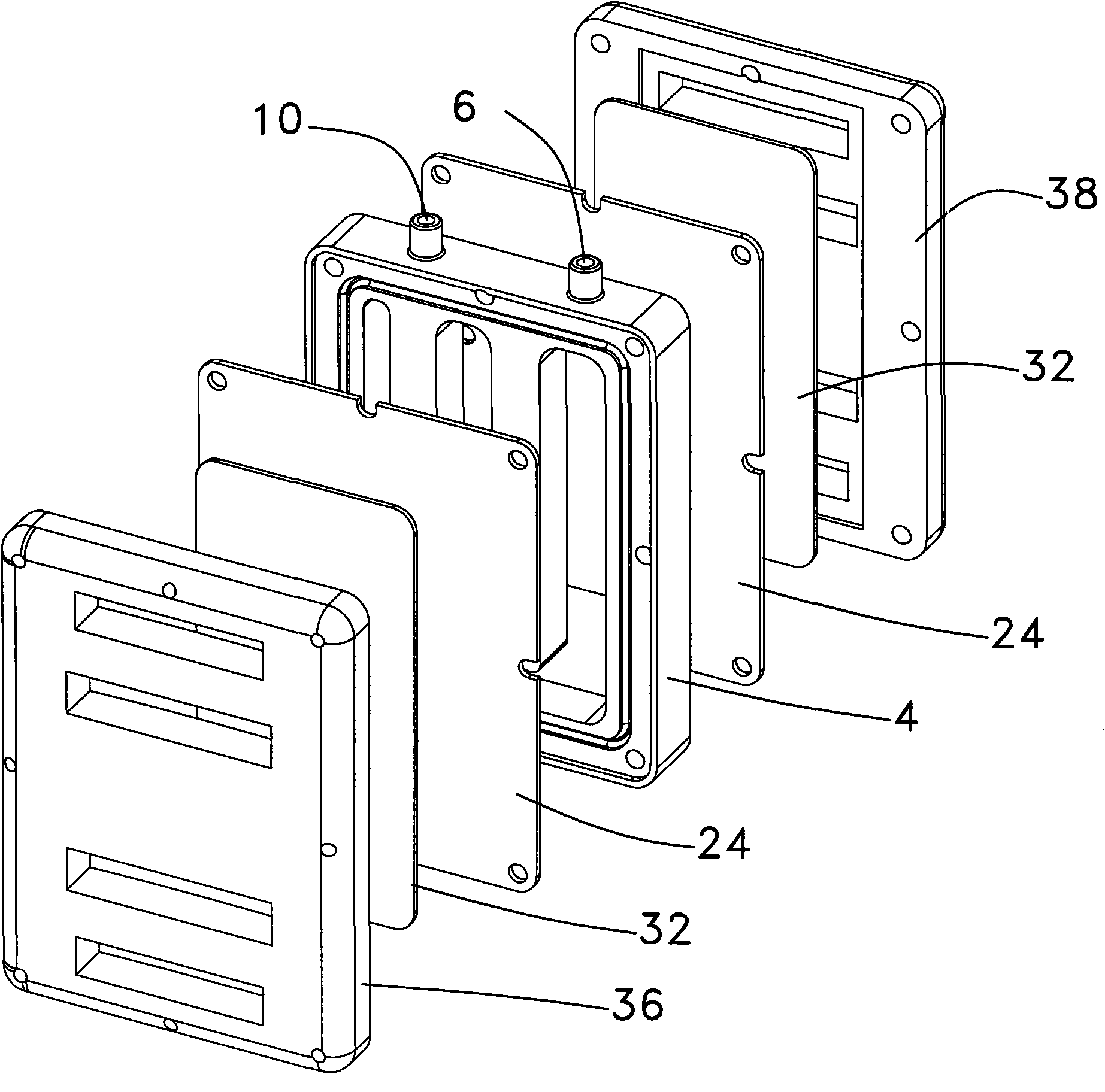

[0052] figure 2It is an exploded view of each main part of the liquid heating device. The liquid heating device 2 comprises a core 4 in the middle part of the device 2 . This core 4 provides a liquid inlet level 6 designated as a first channel 8 through which liquid is introduced into the core 4 . The core 4 also provides a liquid outlet 10 , designated as a second channel 12 , through which the heated liquid leaves the core 4 . image 3 Independently demonstrates core 4 more clearly. refer to Figure 1 to Figure 3 , The water inlet level 6 and the water outlet level 10 and the joint position 11 are adapted to each other. The core 4 is relatively thin because the thickness of the ...

Embodiment 2

[0062] The difference between Embodiment 2 and Embodiment 1 is that the liquid heating device 2 adopts a core 40 with a different structure in Embodiment 2. as attached Figure 7 As shown, here a clearer or narrower channel 42 is attached to the core 40, and the main part of the channel 42 is arranged in a direction parallel to the direction of the water inlet or outlet. It can be understood here that when comparing the core 4 in the first embodiment, the core 40 has a relatively large inner surface area, so that the water source is more inclined to contact the surface of the channel 42 when flowing through, which can increase the heat transfer to the liquid. efficiency.

Embodiment 3

[0064] Figure 8a , 8b and 8c disclose three other different cores 44, 46 and 48, which have in common that the water inlet and outlet levels are set on top of the core. When they are all rotated 90 degrees clockwise, it can be considered that the water inlet level and the water outlet level are set on the side of the core, and the water outlet level is set above the water inlet level. One of the characteristics of the core 44 is that the water inlet level 50 and corresponding channels 52 are lower than the water outlet level 56 and corresponding channels 54 . Likewise, the core 44 supplies a temporary storage unit 58 or reservoir on the other side of the channel 52 . The temporary storage component 58 can be used to temporarily store gas or vaporized water in the core 44 , thus making it difficult for the gas to flow out of the core 44 . This reduces the amount of steam vented at the outlet level of the liquid heating unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com