Insert type air preheater with same inlet-outlet temperature difference of heat exchange tubes

A technology for air preheaters and heat exchange tubes, which is applied in lighting and heating equipment, combustion methods, and indirect carbon dioxide emission reduction, etc. Low service life and other problems, to achieve the effects of enhanced fluid mixing, increased heat transfer coefficient, and reduced cost

Inactive Publication Date: 2010-08-25

杭州美宝炉窑工程有限公司

View PDF7 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the above method can partially solve the problem of uneven thermal expansion of each row of heat exchange tubes in the insert air preheater, it needs to use expensive high-temperature-resistant alloy materials or a suspension device with a relatively complicated structure or a complicated heat exchange tube structure, which causes insertion The piece-type air preheater is expensive and has a short service life, which affects the overall performance of the air preheater

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

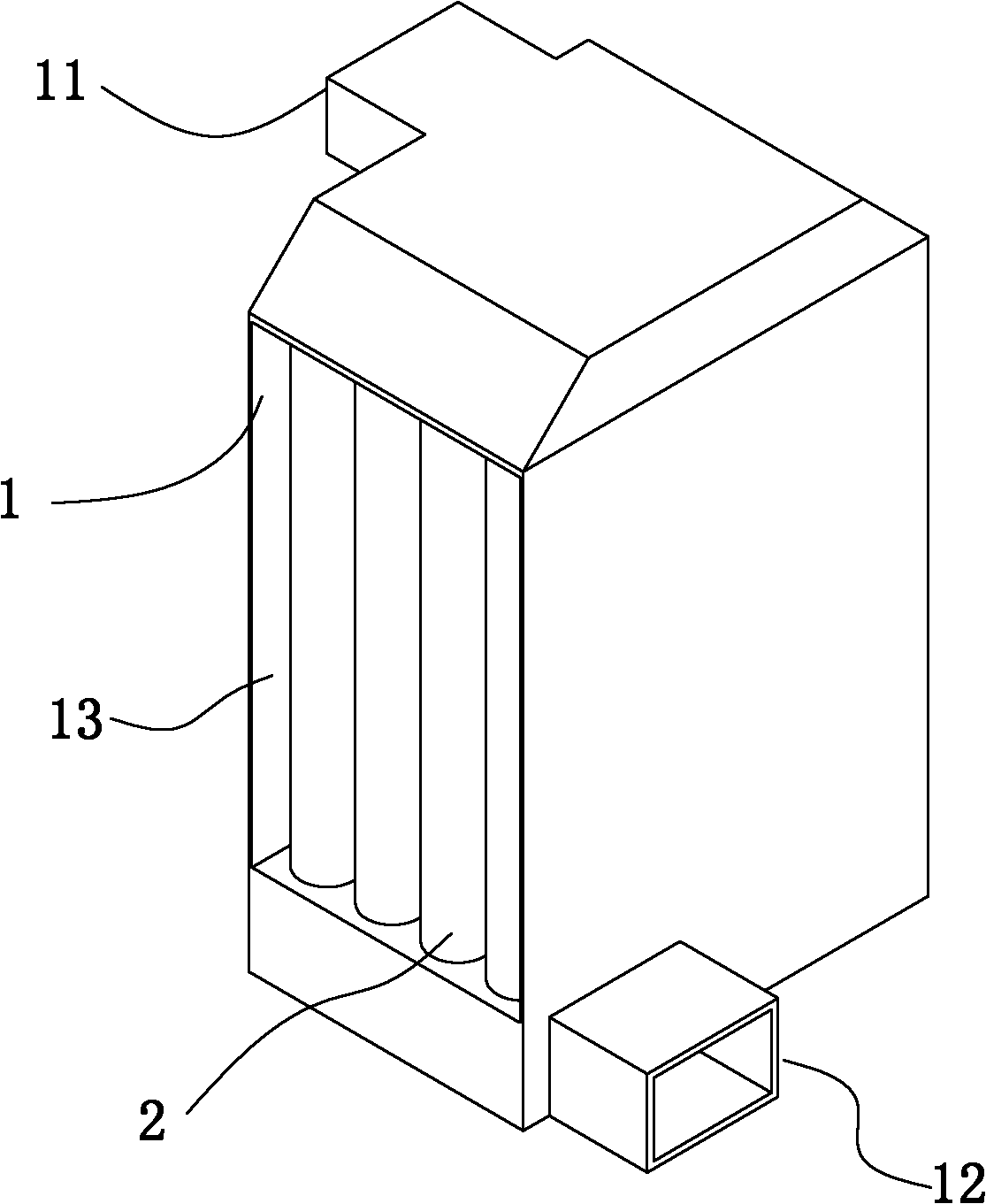

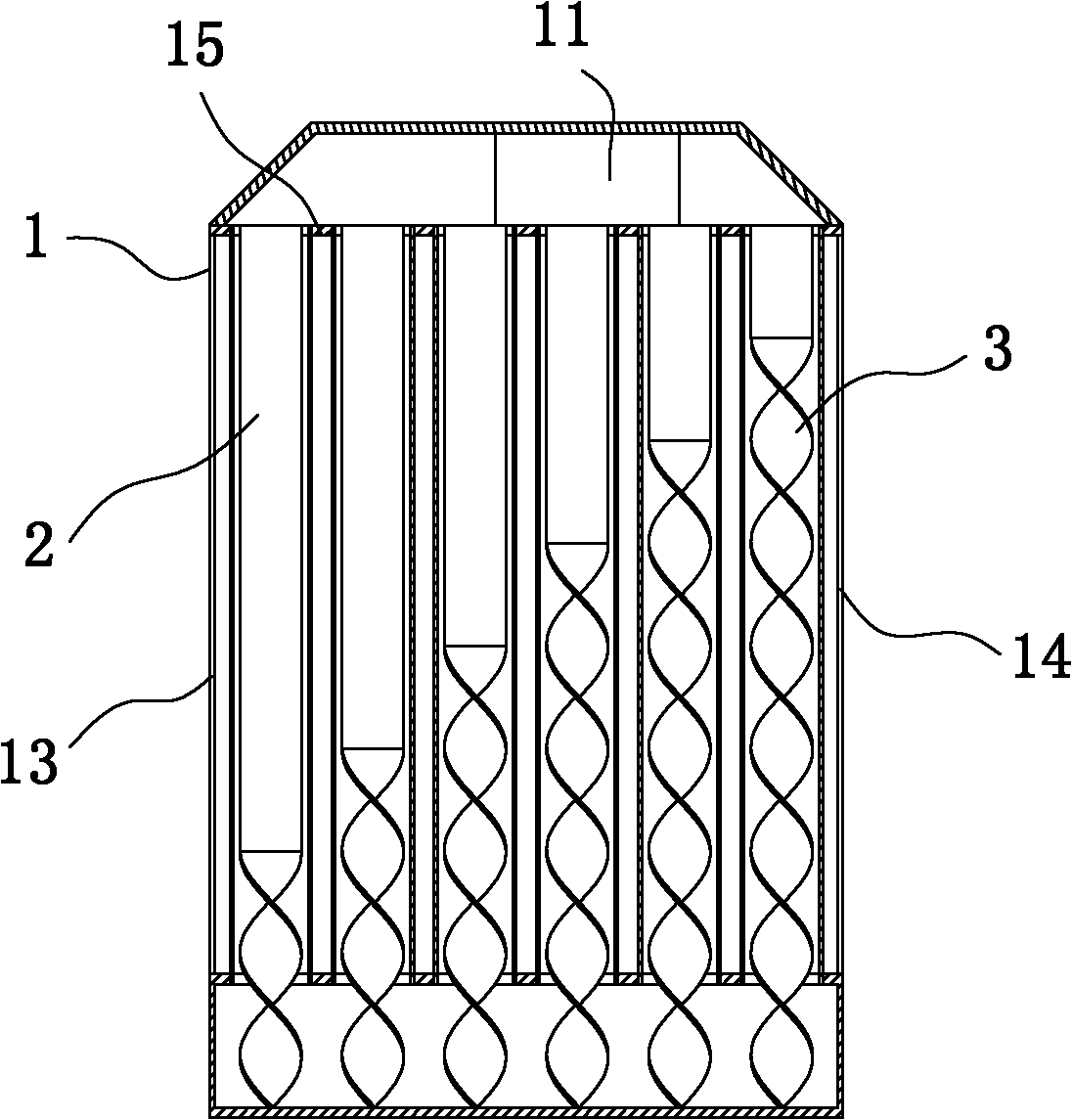

The invention discloses an insert type air preheater with the same inlet-outlet temperature difference of heat exchange tubes, comprising an air bellow and a plurality of rows of heat exchange tubes, wherein the upper end of the air bellow is provided with a cold air inlet, the lower end of the air bellow is provided with a hot air outlet, one side of the air bellow is provided with a smoke inlet, the other side of the air bellow is provided with a smoke outlet, the heat exchange tubes are evenly arranged in the air bellow and communicated with the cold air inlet and the hot air outlet, the heat exchange tubes are internally provided with inserters comprising straight sections and spiral sections, the straight sections are arranged at the inlet sections of the heat exchange tubes, and the spiral sections are arranged at the outlet sections of the heat exchange tubes. The percentage of the lengths of the straight sections of the inserters in each row of the heat exchange tubes in total length is gradually decreased from the smoke inlet to the smoke outlet. The insert type air preheater with the same inlet-outlet temperature difference of heat exchange tubes can reduce tube wall temperature differences among the heat exchange tubes to enable air to be heated in the heat exchange tubes to have the same inlet-outlet temperature difference, thereby achieving the optimal comprehensive heat exchange effect.

Description

technical field The invention relates to an air preheater, in particular to a plug-in air preheater used in chemical industry, metallurgy, energy power, building materials and other industrial fields. Background technique Insert-type air preheaters are mostly used for flue gas-air heat exchange, and are widely used in waste heat utilization and air preheating of hot blast stoves, heating furnaces, industrial furnaces, boilers, etc. in chemical, metallurgy, energy power, building materials and other industrial fields. It can fully recover waste heat and provide pure high-temperature air, saving a lot of energy. The existing insert air preheater has a simple structure and convenient material selection, but the front row of heat exchange tubes near the flue gas inlet is directly radiated by the space in front of the heat exchange tubes, and the temperature is higher than other tubes, which leads to the The thermal expansion of the heat pipes is different, and when one heat exc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F23L15/00

CPCY02E20/34

Inventor 姜昌伟童永清邓鹏姜建荣

Owner 杭州美宝炉窑工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com