Aviation piston type engine driving torsional damper

A piston engine and damper technology, applied in springs/shock absorbers, mechanical equipment, vibration suppression adjustment, etc., can solve problems such as poor vibration damping effect, achieve strong ability to absorb large torque changes, reduce torsion Stiffness, the effect of increasing torsional vibration damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be described in detail below through a best embodiment in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the embodiment.

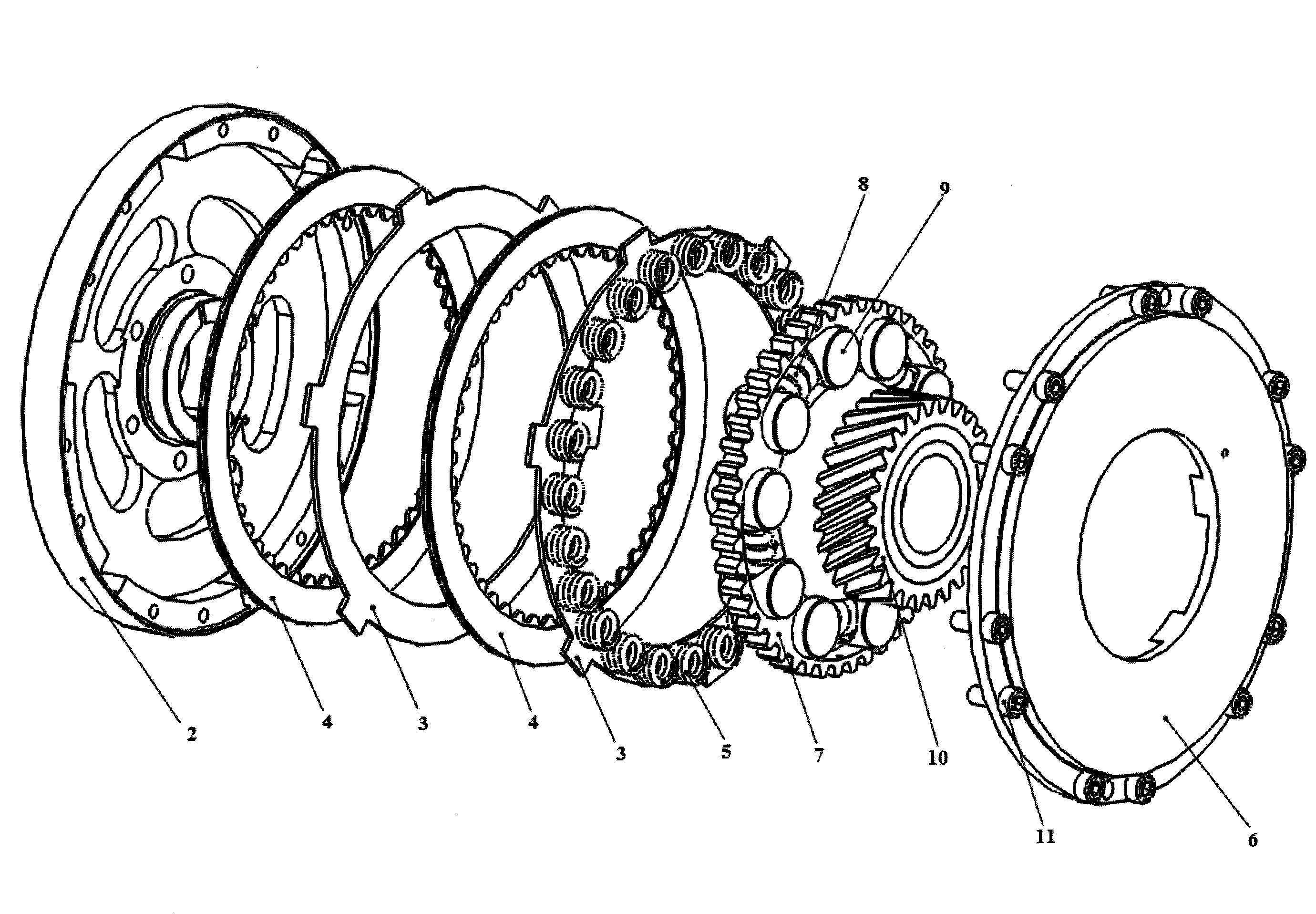

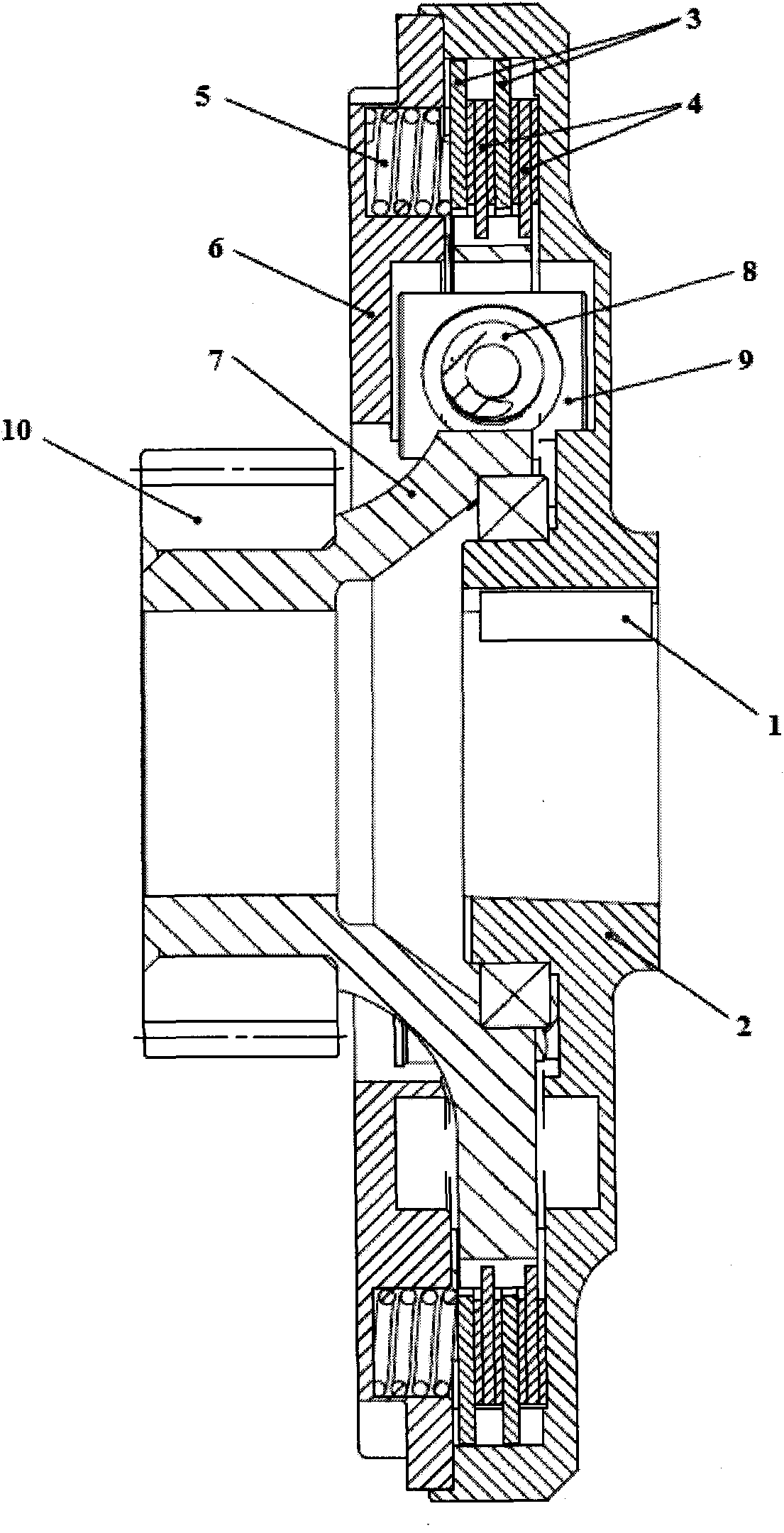

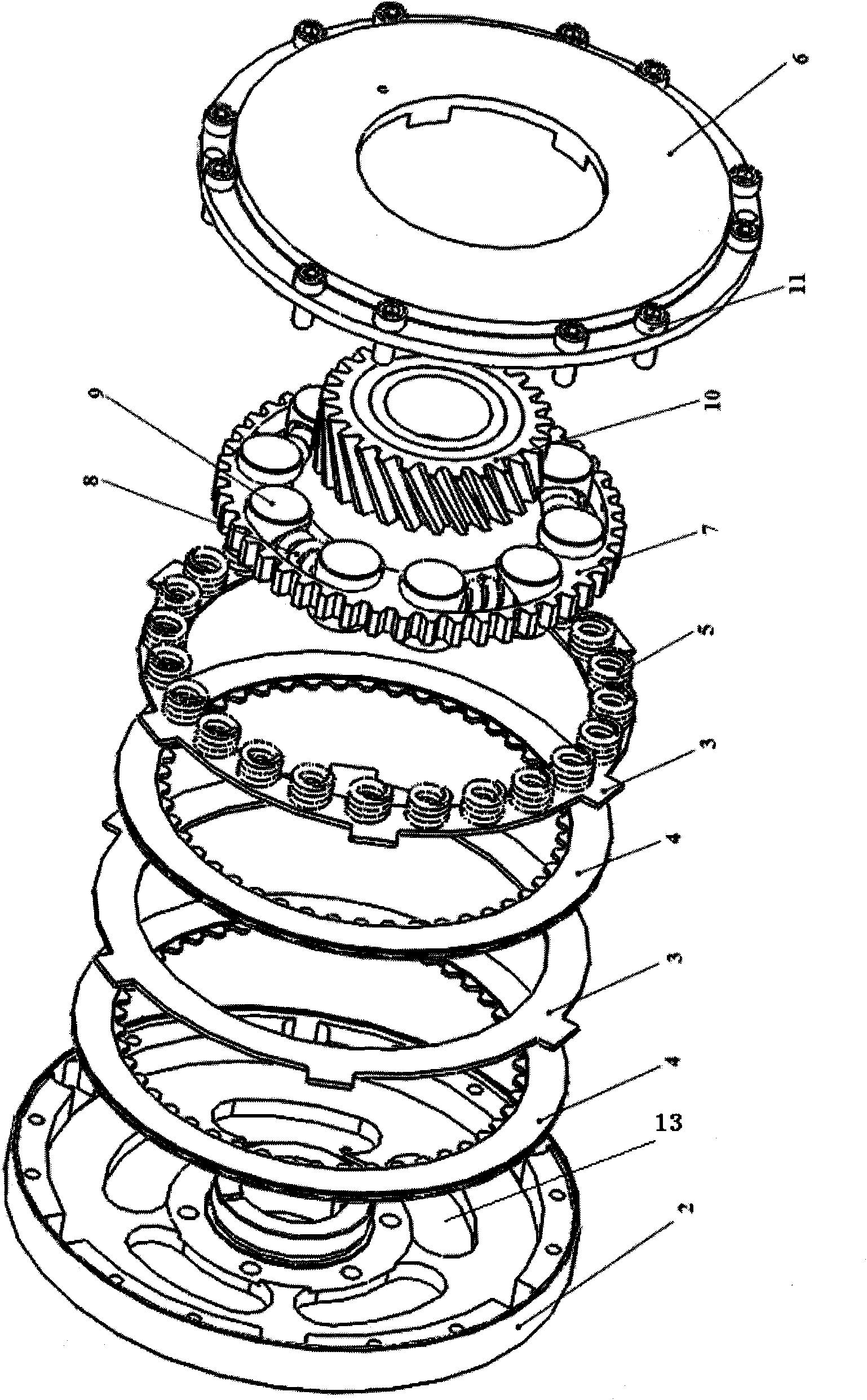

[0021] As shown in Figures 1 to 3, an aviation piston engine torsion damping damper includes: a damper housing 2 as an input component, which is connected to a crankshaft through a flat key 1 and rotates together with the crankshaft;

[0022] A reduction gear 10 as an output component, and a fixed ring gear 7 fixedly connected to it;

[0023] The damper housing 2 and the fixed gear ring 7 are attached to each other, and 5 waist-shaped grooves 13 are respectively opened for the insertion of 5 sets of elastic connecting keys. The damper housing 2 is connected by the elastic connecting keys. The torque is transmitted to the reduction gear 10; each group of elastic connecting keys is composed of a pair of spring supports 9 for clamping springs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com