Self-sucking energy-saving high-efficiency water pump

A high-efficiency, water pump technology, applied in the direction of pumps, rotary piston pumps, rotary piston machines, etc., can solve the problems of failing to achieve the use effect and work efficiency, difficult to meet market needs, high noise, etc., and achieve a simple product structure. Design, enhance pumping efficiency, reduce noise

Inactive Publication Date: 2010-08-25

黄武源

View PDF7 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, although the existing water pump structure can provide its basic water pumping function, in actual use, it is found that there are still many deficiencies in its own structure and performance, and it cannot achieve the best use effect and work efficiency.

Its disadvantages are: small flow, low efficiency, high noise, high cost, and it is difficult to meet the increasingly competitive market needs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

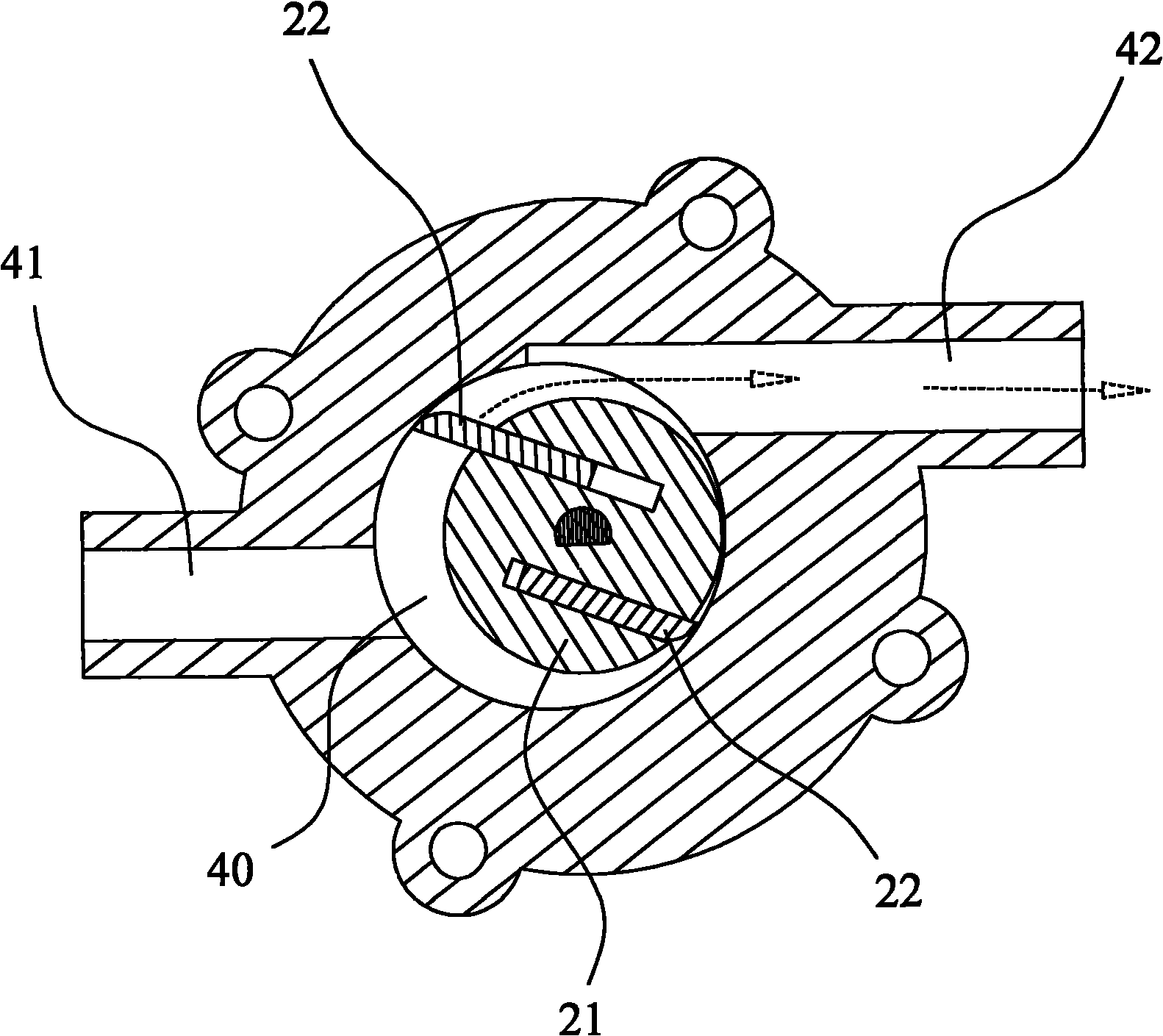

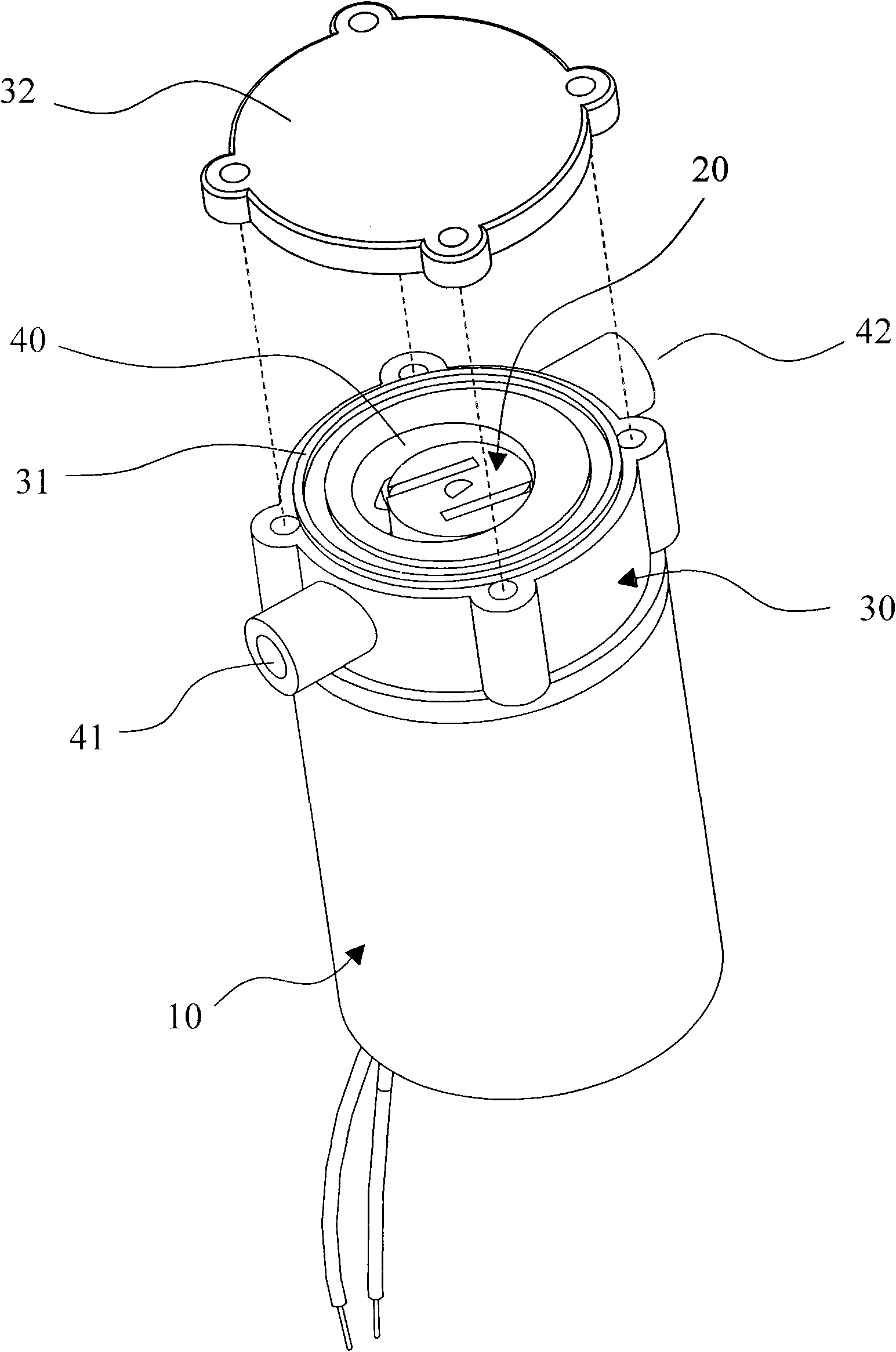

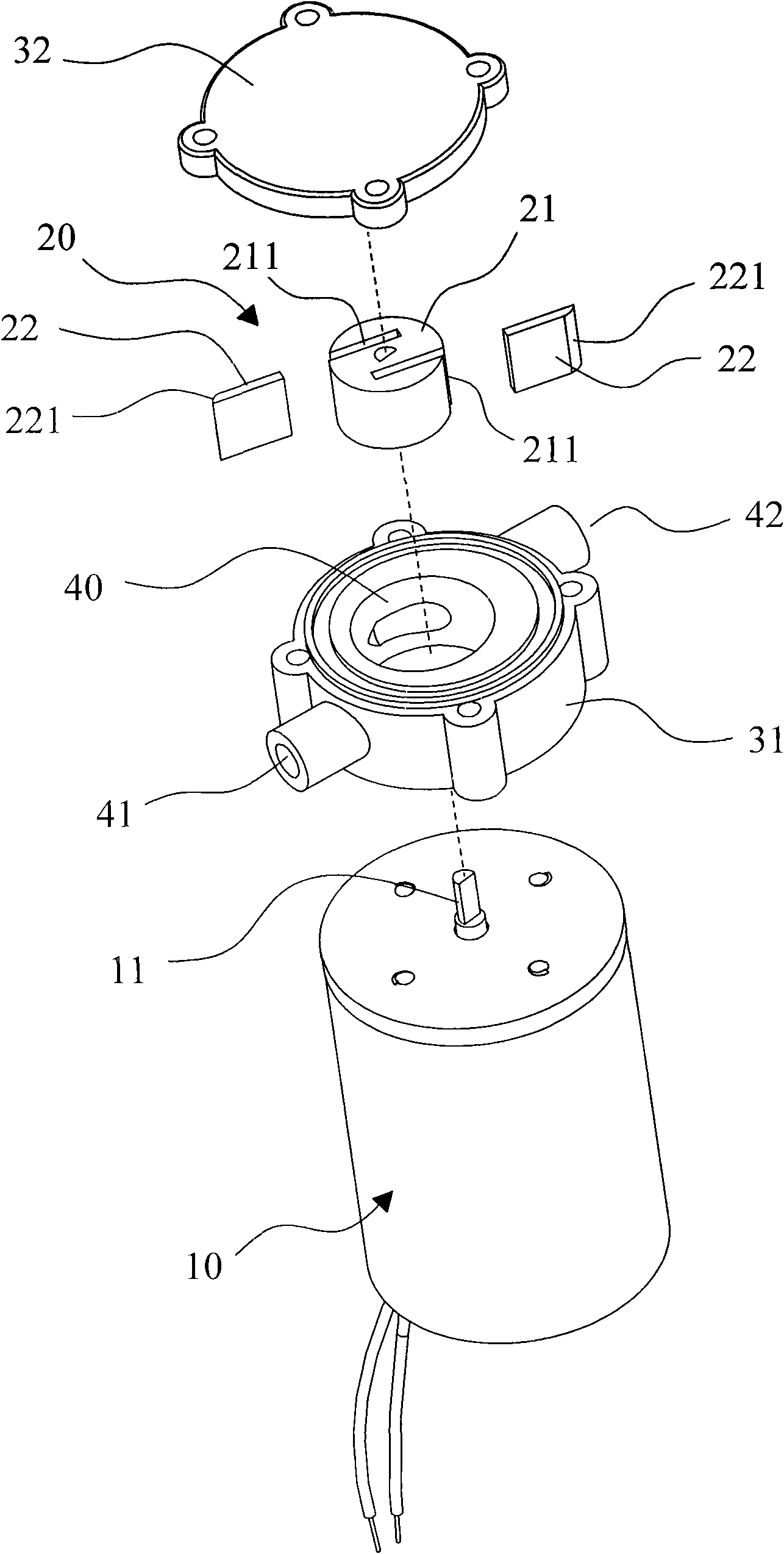

The invention discloses a self-sucking energy-saving high-efficiency water pump, which comprises an impeller and a pump shell, wherein the impeller is positioned in a liquid chamber of the pump shell and connected to a driving device which drives the impeller to rotate to form a water current for water pumping; the liquid chamber has a water inlet and a water outlet; the impeller comprises a hub and blades; the liquid chamber is eccentrically arranged relative to the hub; one side of the hub is close to the inner wall surface of the liquid chamber, so the volume between the other side of the hub and the inner wall surface of the liquid chamber is big, the water inlet of the liquid chamber is communicated with the large volume area and the water outlet of the liquid chamber is communicated with the position, where the volume reduces gradually, of the liquid chamber; and the blades can be moveably arranged in the hub relative to the hub. When the hub rotates, the blades extend outwards under the action of the centrifugal force, the tail ends of the blades are matched with the inner wall surface of the liquid chamber and extend radially along with the volume change of the liquid chamber to drive the water current, and thus, the water current flows towards the water outlet only. The self-sucking energy-saving high-efficiency water pump avoids the diffusion and reflux of the water current, improves the pumping efficiency and the flow and has the advantages of saving the energy and protecting the environment.

Description

Self-priming energy-saving and high-efficiency water pump technical field The invention relates to the technology in the field of water pumps, in particular to a water pump that utilizes the cooperation of an eccentric liquid chamber and movable blades to obtain high-efficiency water pumping. Background technique At present, water pumps have been widely used in water circulation such as electronic refrigerators, ice bladders, hot water bottles, aquarium fish tanks, fountains, solar energy and handicrafts. The structure of the water pump is basically composed of a pump casing and an impeller, and is used with a motor. The pump casing is provided with a water inlet and a water outlet. The impeller is set in the liquid chamber of the pump body, and the outlet is connected to the side of the liquid chamber. The direction of the outlet is consistent with the tangential direction of impeller rotation. Its working principle is to use the motor to drive the impeller to rotate at ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F04C2/344

Inventor 黄武源

Owner 黄武源

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com