High-efficiency separation method of caustic lye

A separation method and technology of caustic lye, applied in chemical instruments and methods, inorganic chemistry, alkali metal compounds, etc., can solve the problems of inconvenient transportation, unfavorable storage, low lye concentration, etc., to eliminate environmental and personal Potential safety hazards, full utilization of materials, and the effect of reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

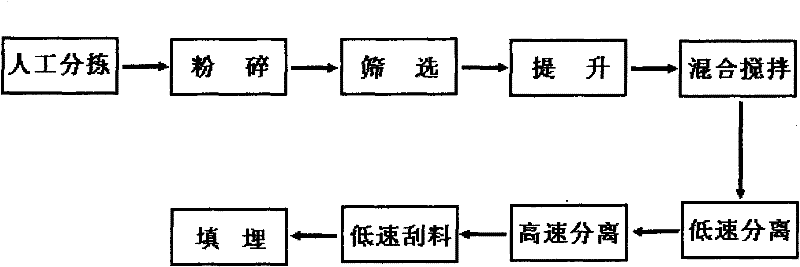

Method used

Image

Examples

Embodiment 1

[0026] Lift the quicklime powder obtained after pretreatment into the causticization tank and carry out causticization reaction under the action of mechanical stirring; gradually discharge the material into a 1200mm centrifugal separator under stirring, and discharge the material at a low speed of 18m / s for 20 minutes. Separation at a high speed of 50m / s for 30 minutes, the water content of the unloaded lime slag is 5.3%, and there is no slippery feeling in the hand, which meets the conditions of safe landfill.

Embodiment 2

[0028] Lift the quicklime powder obtained after pretreatment into the causticization tank and carry out causticization reaction under the action of mechanical stirring; gradually discharge the material into a 1200mm centrifugal separator under stirring, and discharge it for 18 minutes at a low speed of 20m / s. Separation at a high speed of 55m / s for 25 minutes, the water content of the unloaded lime slag is 4.5%, and there is no slippery feeling in the hand, which meets the conditions of safe landfill.

Embodiment 3

[0030] Lift the quicklime powder obtained after the pretreatment into the causticization tank and carry out the causticization reaction under the action of mechanical agitation; gradually discharge the material into a 1200mm centrifugal separator under agitation, and discharge it for 15 minutes at a low speed of 25m / s. Separation at a high speed of 60m / s for 20 minutes, the water content of the unloaded lime residue is less than 5%, and there is no slippery feeling in the hand, which meets the conditions of safe landfill.

[0031] Features of the present invention:

[0032] 1. The moisture content of the calcium carbonate slag filtered by the prior art vacuum filter is greatly reduced, and the calcium carbonate slag can be safely landfilled, energy saving and emission reduction, and good environmental protection benefits.

[0033] 2. The present invention omits the process of heating, evaporating and concentrating, not only has a short technological process, but also is easy t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com