Pneumatic tire

A technology for pneumatic tires and tires, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve the problem of insufficient effect, inability to ensure tire block rigidity, and deterioration of braking performance on icy and snowy roads and other problems, to achieve the effect of suppressing the ground area and suppressing the reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

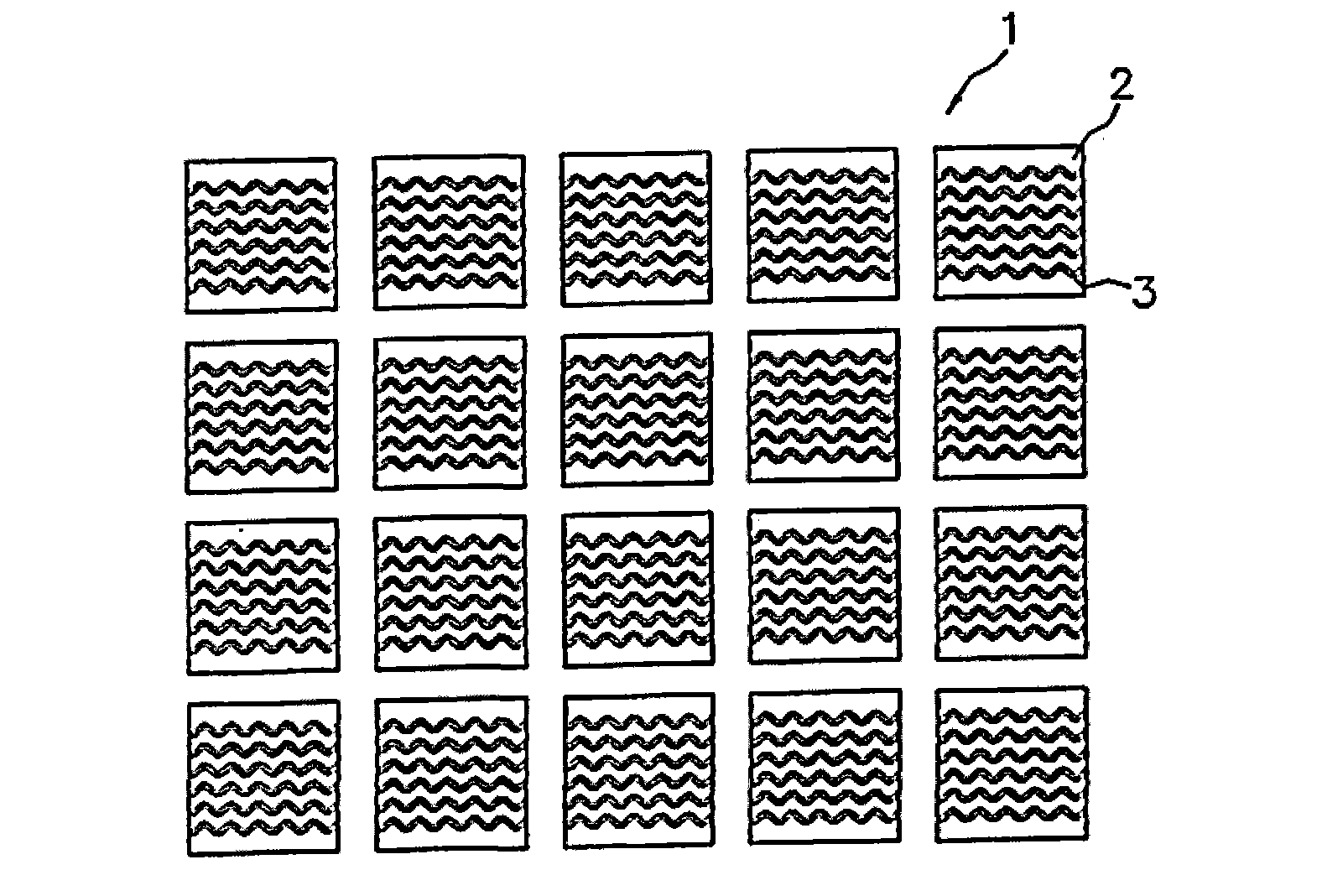

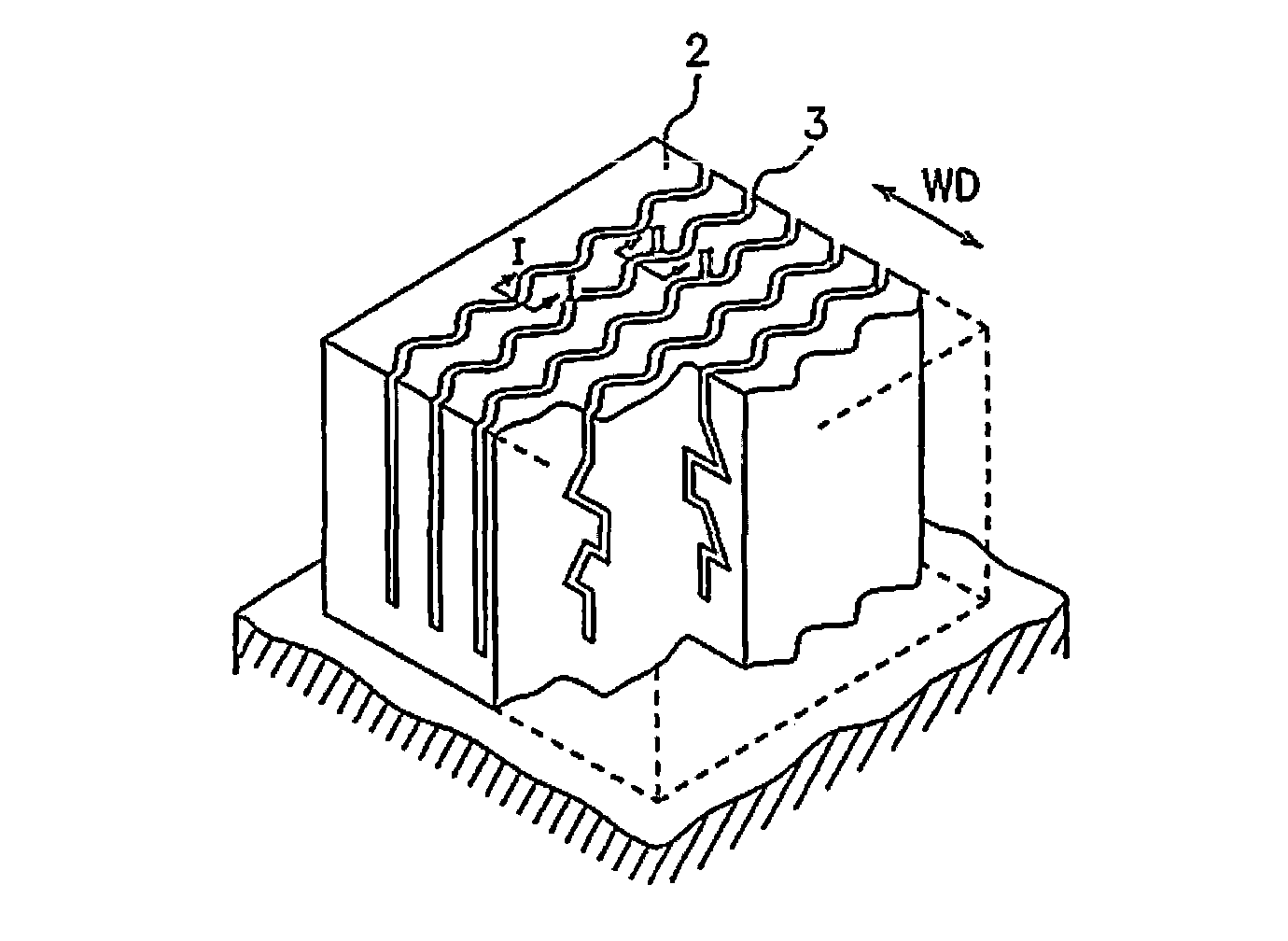

[0039] (1) In the above-mentioned embodiment, an example of a pneumatic tire having blocks 2 in which a plurality of sipes 3 are formed on the tread 1 is shown. In the present invention, it may be a pneumatic tire having a rib as a land portion, A pneumatic tire in which sipes 3 are formed on the ribs.

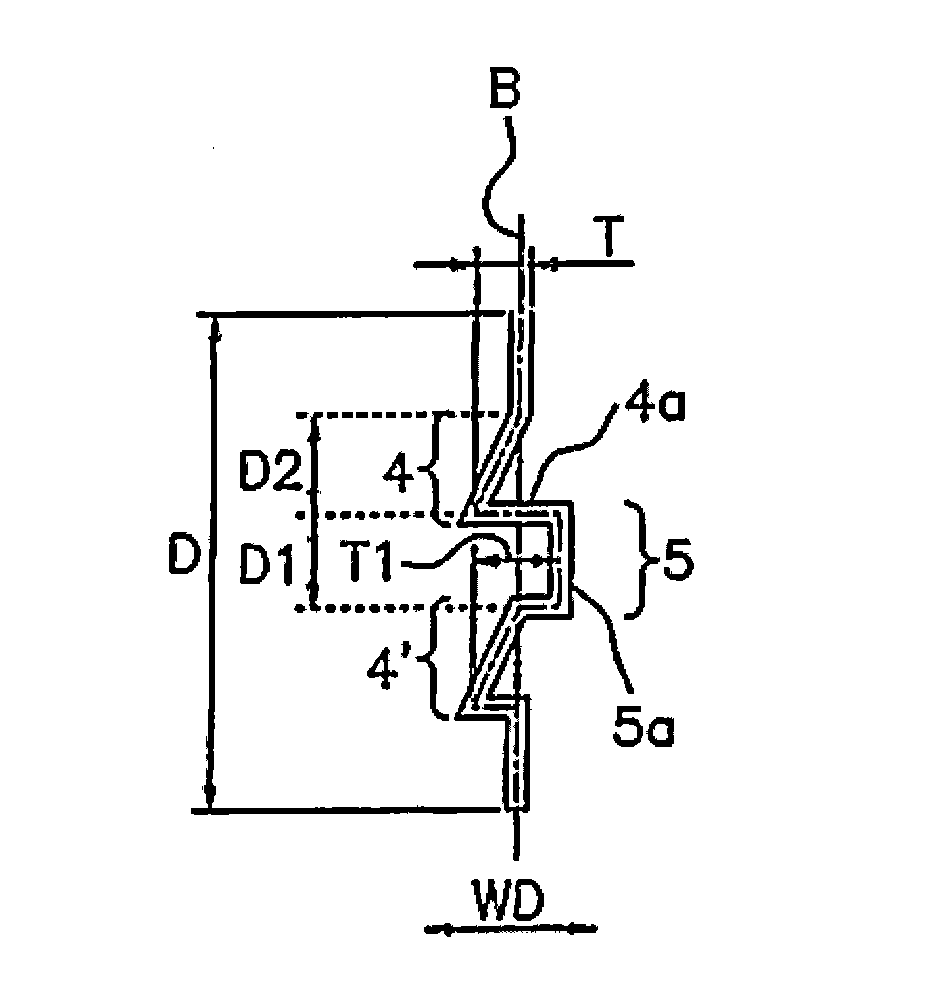

[0040] (2) In the above-mentioned embodiment, there is shown the concave portion 4 with a concave longitudinal section and the convex portion 5 with a convex longitudinal section on the outer top and the inner top with respect to the reference plane B from the side close to the tread of the block 2 . Sipe 3 example. However, in the present invention, if Figure 5 As shown in (a), even if the sipe 3 has only the convex portion 5, the engaging force in the depth direction of the sipe can be sufficiently increased, and the suppressing effect is hardly affected by the collapse direction of the sipe 3. Therefore, even when the sipe 3 has only the convex portion 5 , it is possible...

Embodiment 1

[0051] exist figure 1 In the tread pattern shown, the formation Figure 2 ~ Figure 4 For the sipes 3 of the shape shown, the sipes 3 are manufactured with a sipe width of 0.3 mm, a sipe depth D of 7 mm, a half-length T of the amplitude of the wavy line on the surface of the block 2 of 0.7 mm, and a concave portion A pneumatic tire in which the maximum sipe width direction length T1 of the flat surface 4 a of 4 is 1.4 mm, the sipe depth direction length D1 of the convex portion 5 is 1.3 mm, and the sipe depth direction length D2 of the concave portion 4 is 1.3 mm. Using this tire, the performance evaluations described above were performed, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com