Electric winding body and transformer having forced cooling

A technology for electrical windings and transformers, applied in the field of transformers, can solve problems such as the inability to provide structural space for transformers, and achieve the effects of good cooling, improved cooling, and extended working life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

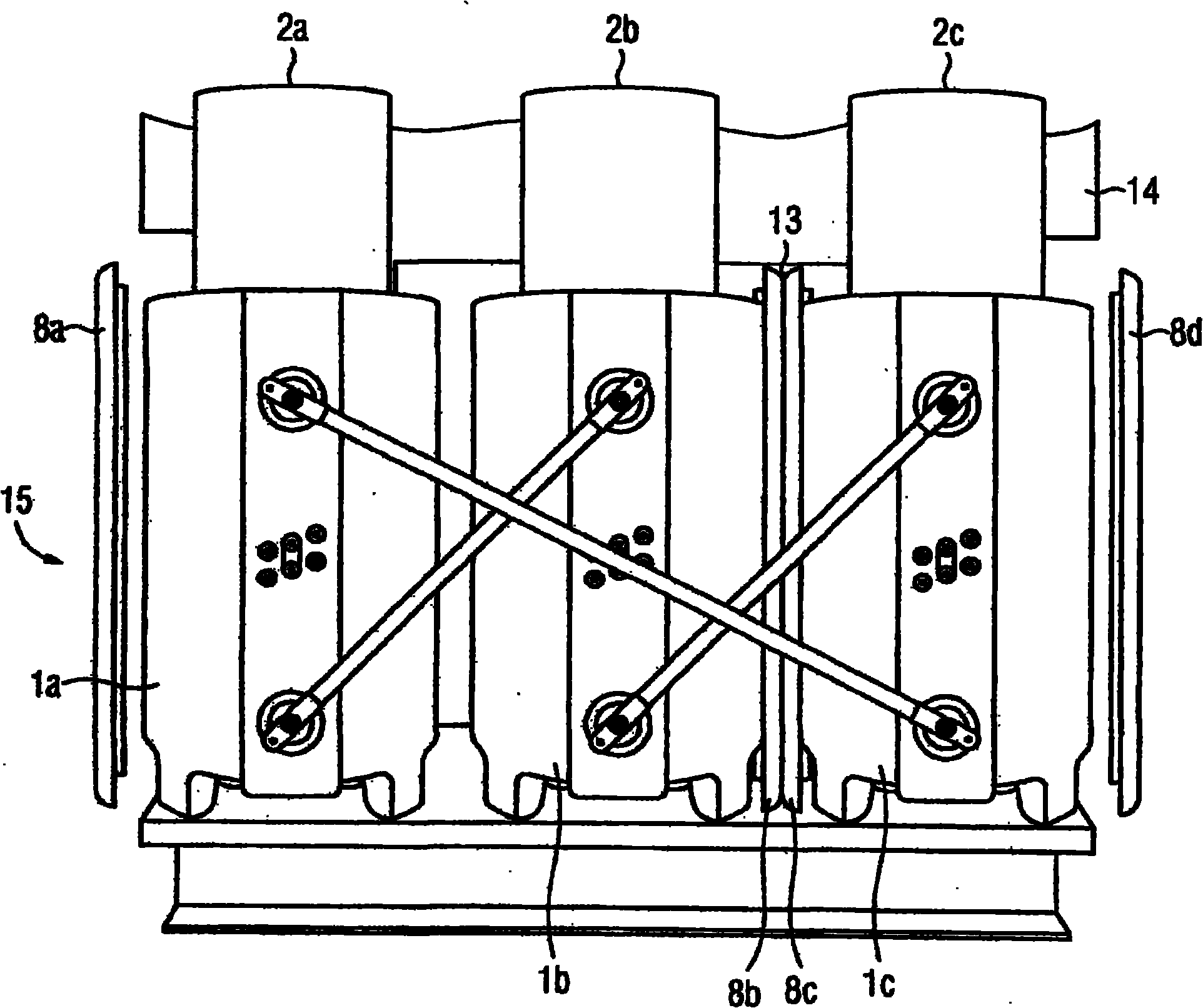

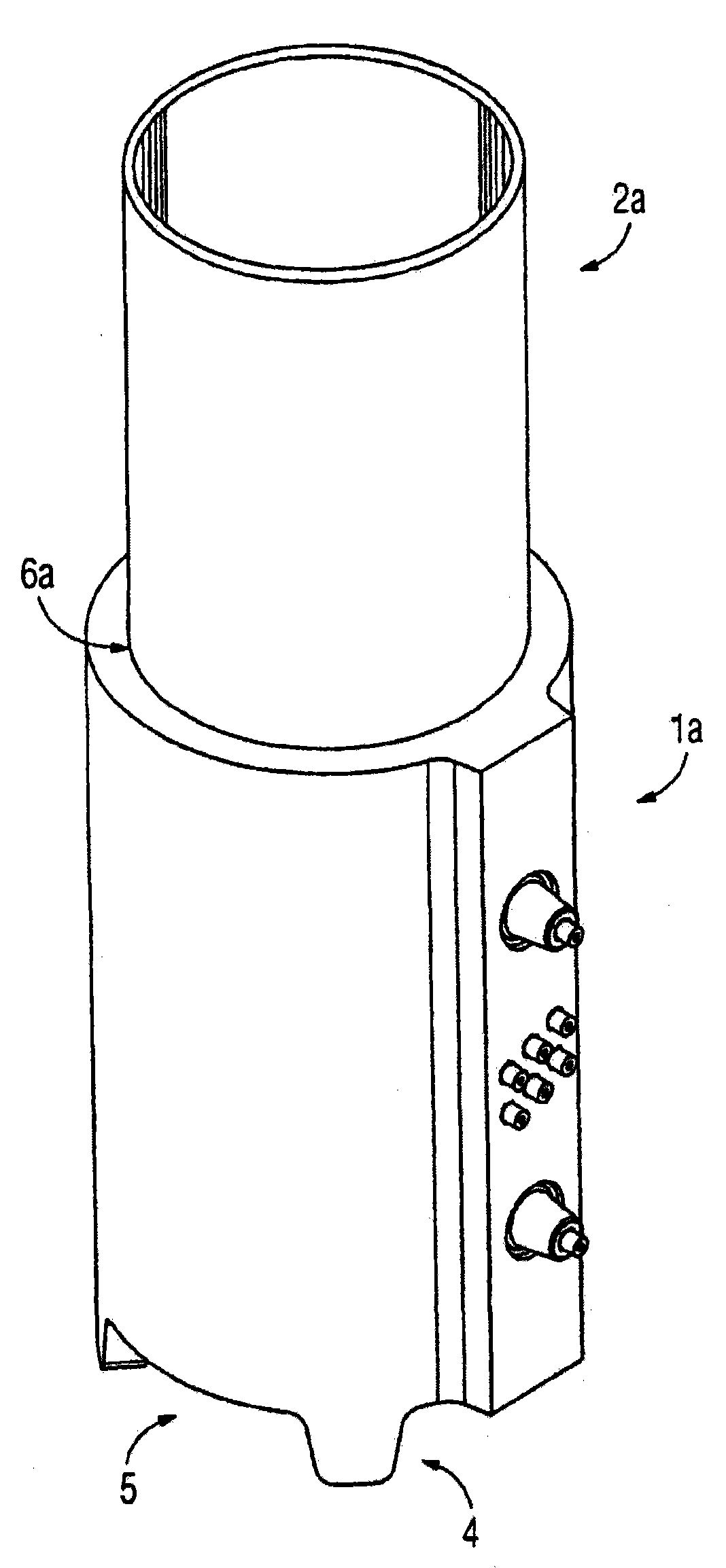

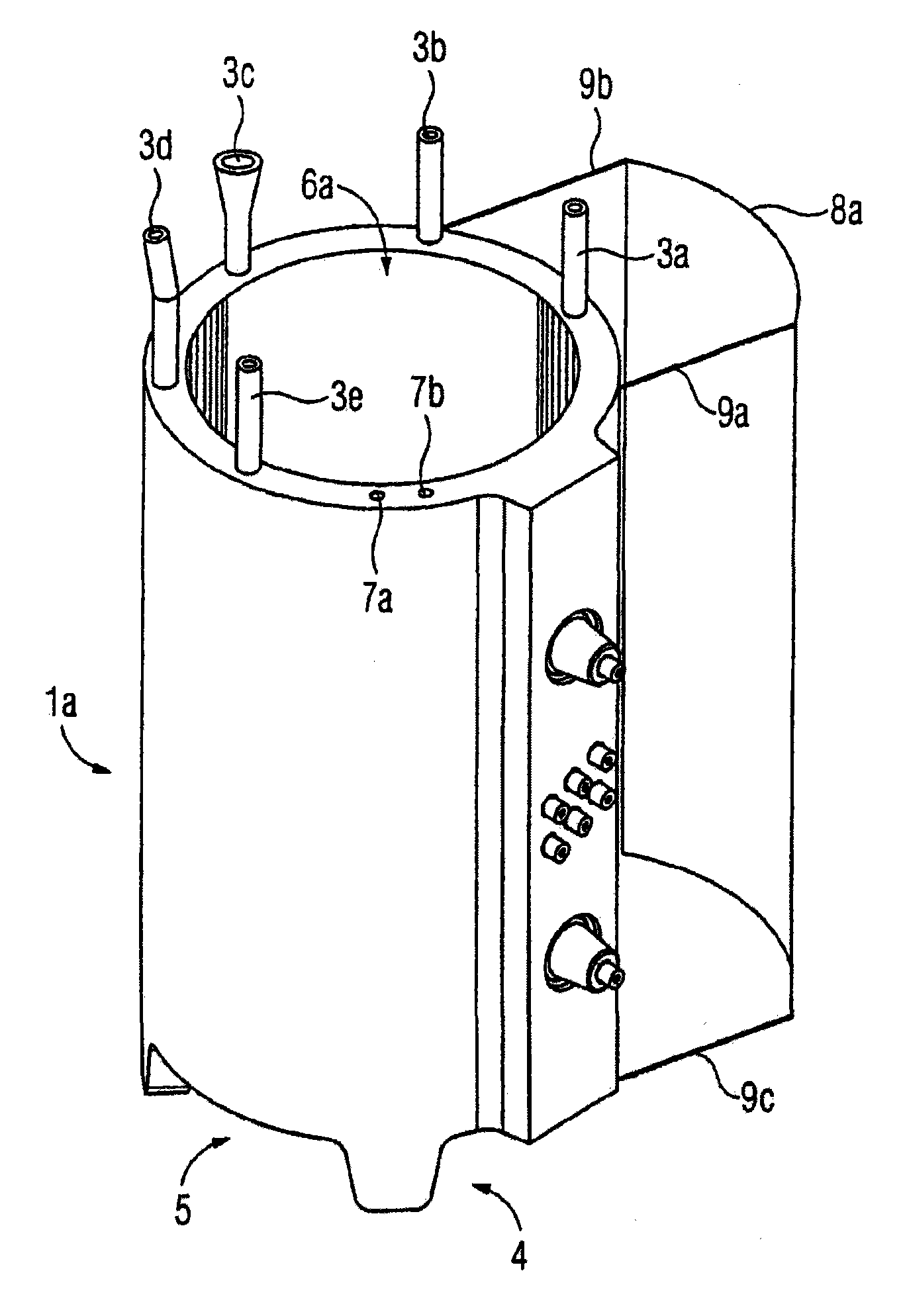

[0039] FIG. 1 shows a perspective view of an electrical winding body 1a with a base 4 forming a gap 5 below the electrical winding body 1a. Air can flow from below through the gap 5 into the through channels 10a, 10b, 10c (10a not shown). A magnetizable iron core (not shown) is inserted into the through central channel 10a of the electrical winding body 1a, so that the electrical winding body 1a can be used as a component of a transformer. An extension part 2 a , which is designed, for example, in the shape of a cylinder, can be inserted into the through channel 10 a. Coolant, in particular air, can escape from the electrical winding body 1 a through holes in the upper part of the cylinder. Air enters one of the through-channels 10 a to 10 c via the gap 5 and exits the bore of the extension 2 a by means of the chimney effect. The influence of the flow and convection conditions directly above the end faces of the electrical winding body 1 a is largely reduced or prevented by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com