Convex closure structure

A convex hull and bottom plate technology, applied to the circuit layout on the support structure, electrical equipment structural parts, electrical components, etc., can solve problems such as deformation of the back plate 4

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

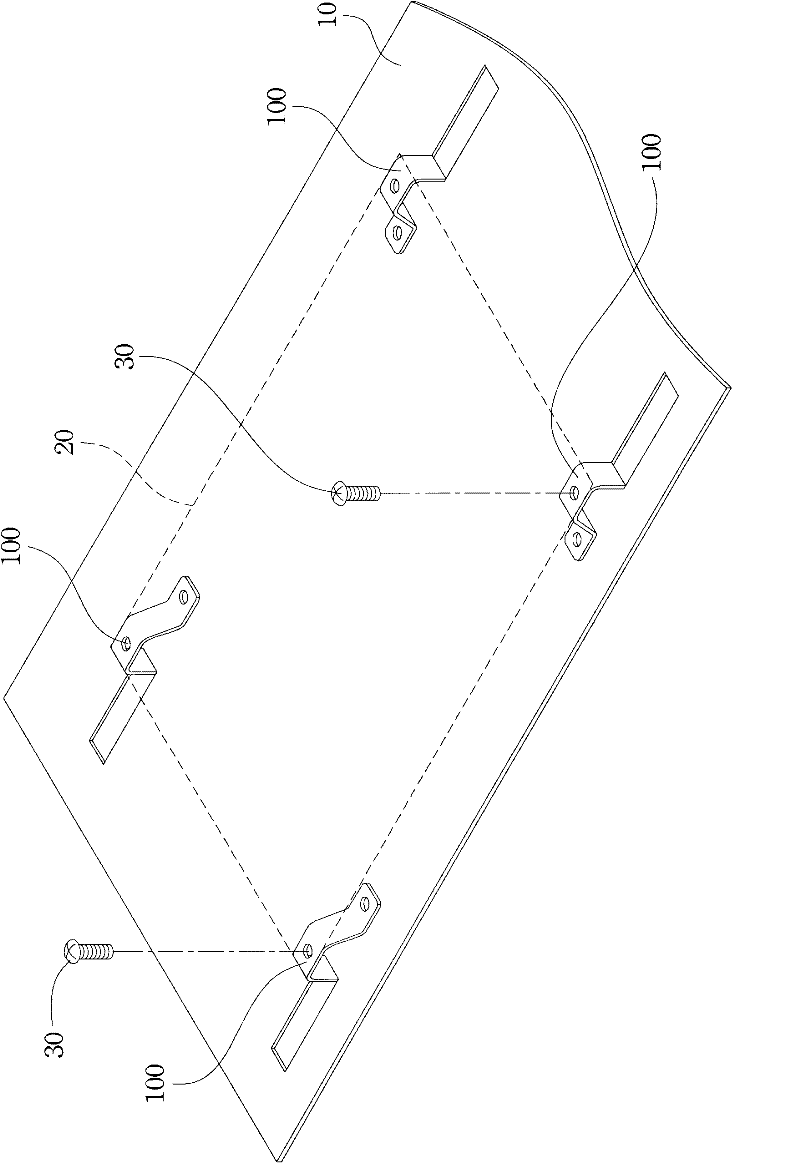

[0043] With reference figure 2 , Is a schematic diagram of the location of the convex hull structure of the present invention. The convex hull structure 100 proposed in the present invention is arranged on the back plate 10 of the electronic device, corresponding to the position of the locking screw 30 of the external element 20, and can be used for locking the external element 20 on the back plate 10 of the electronic device.

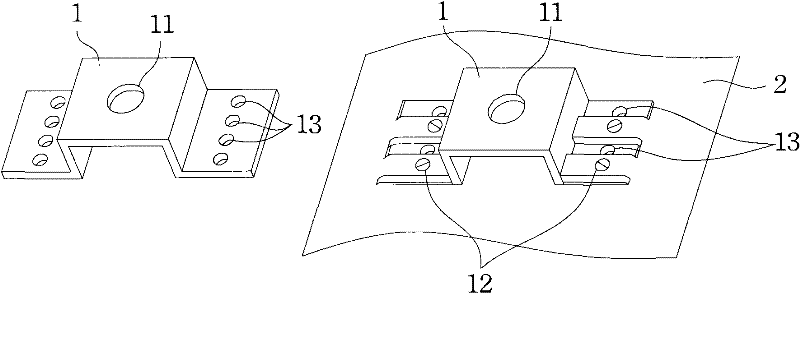

[0044] With reference Figure 3A , 3B , Is a schematic diagram of Embodiment 1 of the convex hull structure of the present invention. The convex hull structure 100 of the present invention is composed of at least a bottom plate 110, a bending piece 120, a fastener 130, and a fastener hole 140.

[0045] Such as Figure 3A As shown, the bottom plate 110 has an upper surface 111. The bent piece 120 is a long plate cut at a specific position of the bottom plate 110 and connected to the bottom plate 110 with a connecting end 121. The bent piece 120 is bent ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com