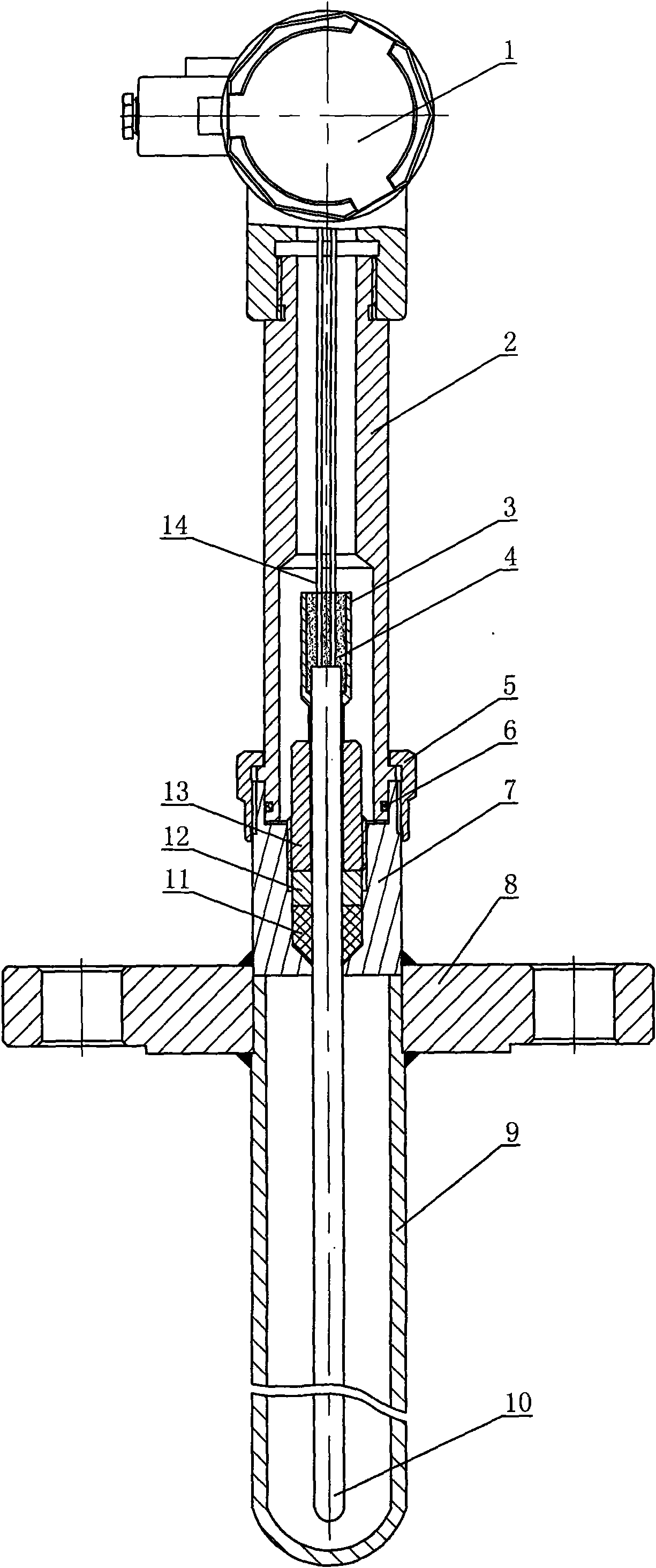

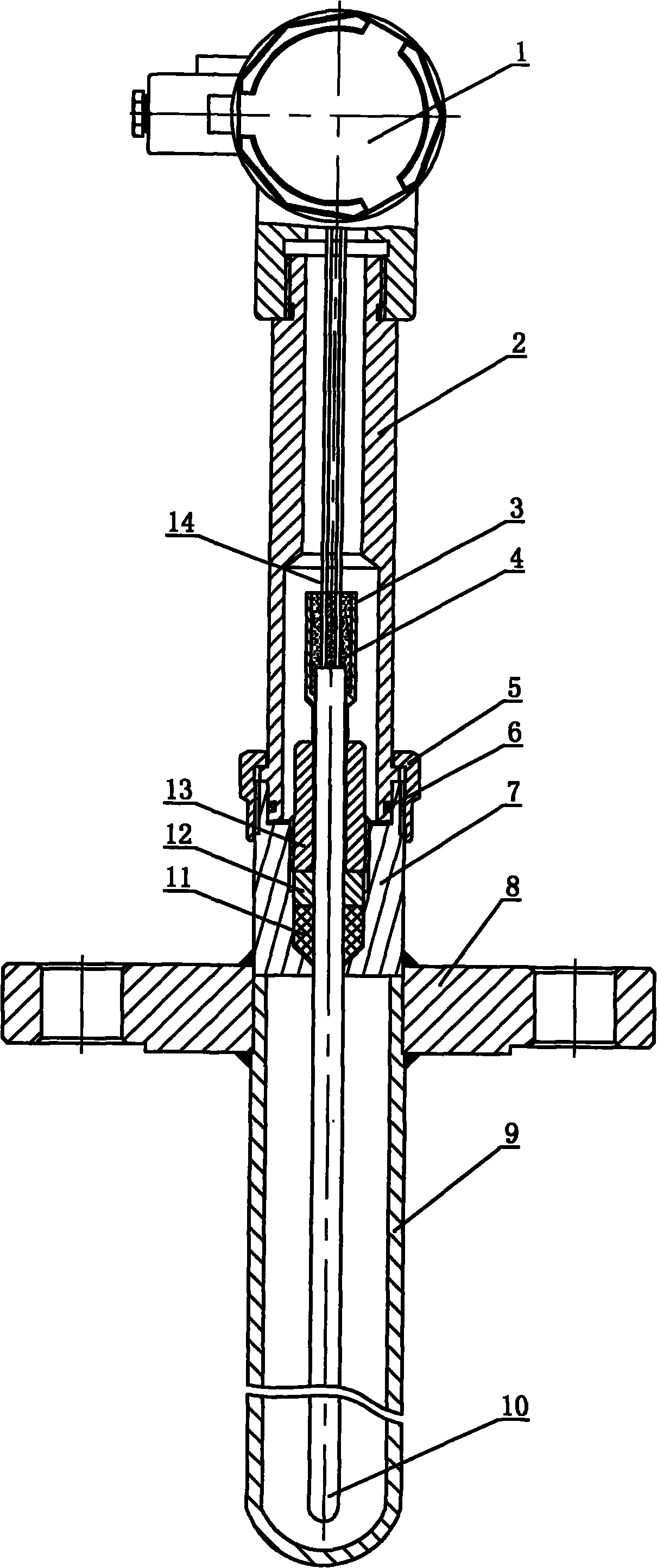

Sealed leakage-resistant thermal couple (resistor)

A thermocouple and leak-proof technology, which is applied in the direction of thermometers that are directly sensitive to heat/magnetic elements, measuring heat, and using electrical devices, etc., can solve the problem of non-adjustable length of measuring elements, no sealing leak-proof device, and maintenance High cost and other problems, to achieve the effect of simple structure, convenient operation and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0016] A sealed leak-proof thermocouple (resistance), which is composed of a junction box 1, a protective sleeve and a temperature measuring element 10. The protective sleeve is coaxially installed by an upper protective sleeve 2 and a lower protective sleeve 9. , the upper end of the upper protective casing is fixed on the junction box, the connecting wire 14 of the temperature measuring element is fixed on the junction box and placed in the protective casing, and a connecting flange 8 is fixed on the lower protective casing, wherein the upper protection A leak-proof seal seat 7 is fixed coaxially between the casing and the lower protective sleeve, the upper end of the leak-proof seal seat is coaxially installed with the upper protective sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com