Measuring device during machining of cylindrical grinder

A technology for measuring devices and cylindrical grinding machines, which is applied to metal processing equipment, parts of grinding machine tools, manufacturing tools, etc., can solve problems such as poor stability, inconvenience, and inconvenient measurement, and achieve good stability and convenient adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

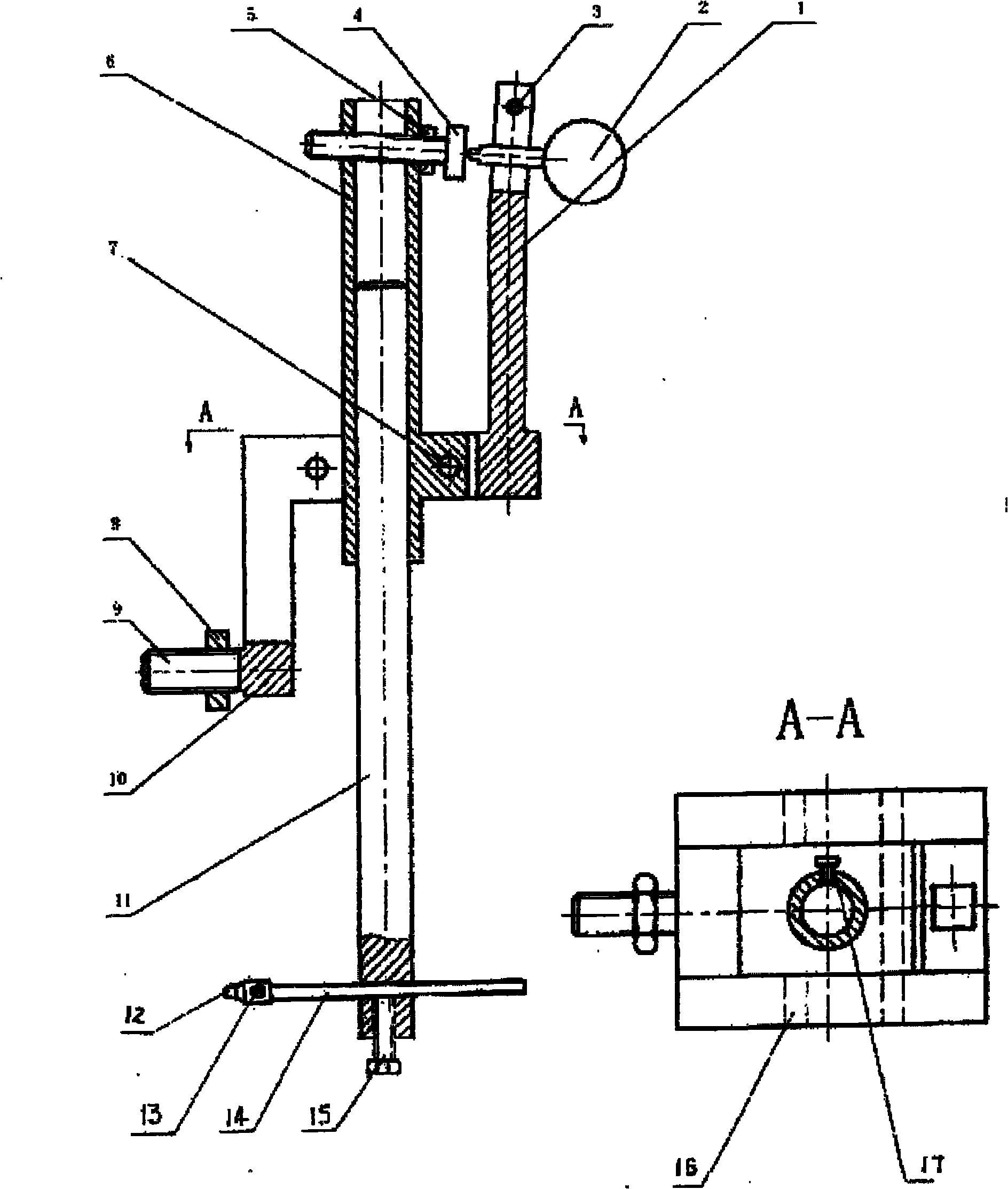

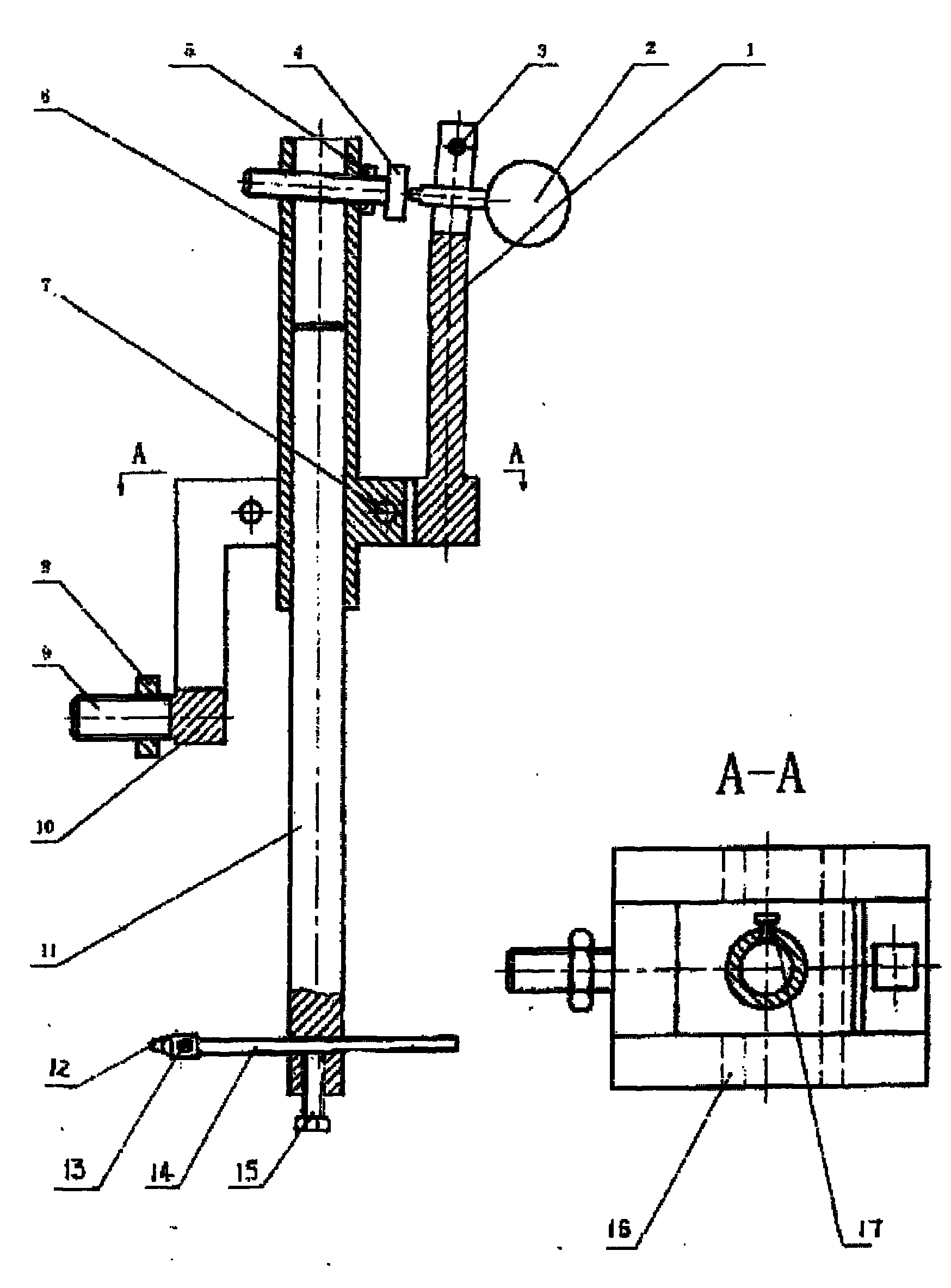

[0018] Such as figure 1 Shown: a cylindrical grinding machine processing measuring device, including a measuring device main body 10, a measuring rod movable sleeve 6, a measuring rod 11, a dial indicator 2, a measuring head 12, and an adjustment device, etc., a total of 17 parts. The specific embodiment is that the dial indicator 2 is vertically fixed on the dial indicator fixing rod 1 of the main body of the measuring device through the fastening screw 3, the dial indicator adjustment rod 4 is fixed at the end of the measuring rod movable sleeve 6 through the lock nut 5, and the measuring rod moves The cover 6 is installed on the middle and upper part of the main body 10 of the measuring device by means of the pin shaft 7, and the measuring rod 11 is housed in the movable cover 6 of the measuring rod, which is locked and fixed by the locking nut 17. The lower part of the main body of the measuring device is equipped with a brake pin 16, and the front end of the measuring rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com