Galvanometer system correction device and correction method thereof

A technology of correction device and correction method, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve problems such as inefficiency of galvanometer system correction, improve the efficiency of updating and real-time correction calculation, and improve the efficiency of calculation. Machining accuracy and effect of suppressing accuracy drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments described here are only used to explain the present invention, and are not suitable for limiting the present invention.

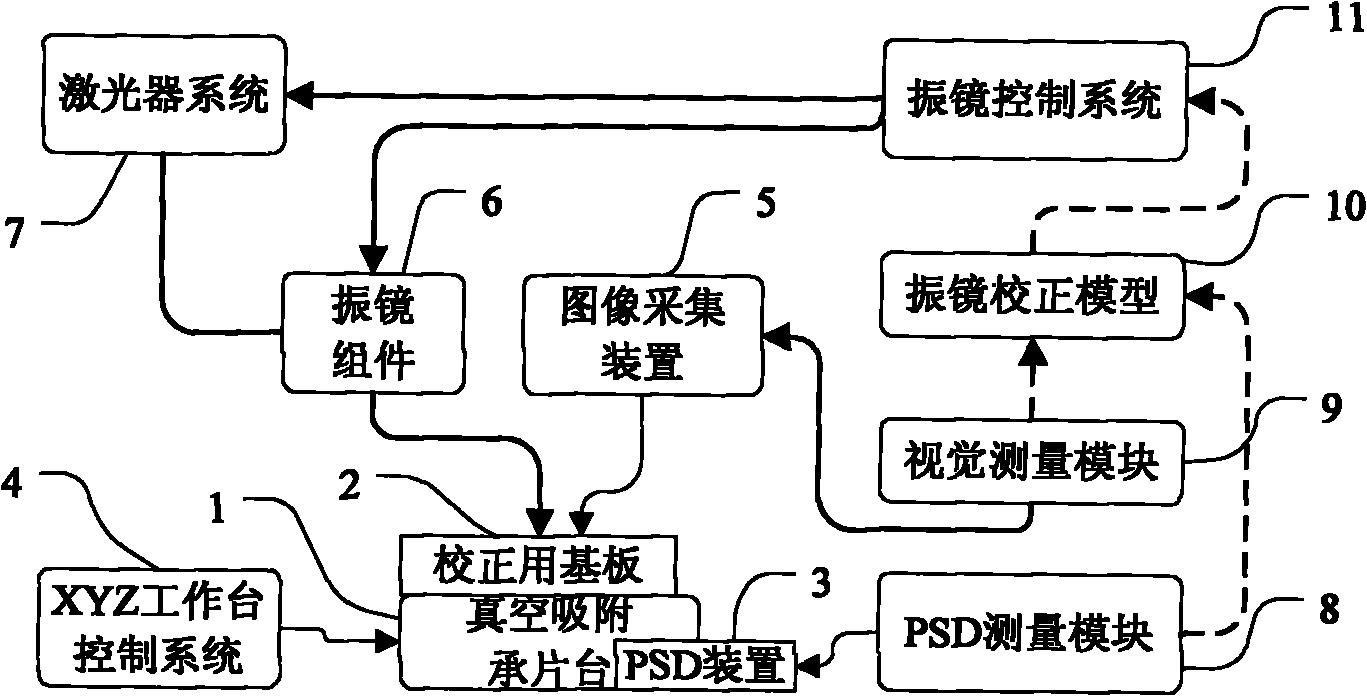

[0031] In this example, if figure 1 As shown, the galvanometer correction device includes:

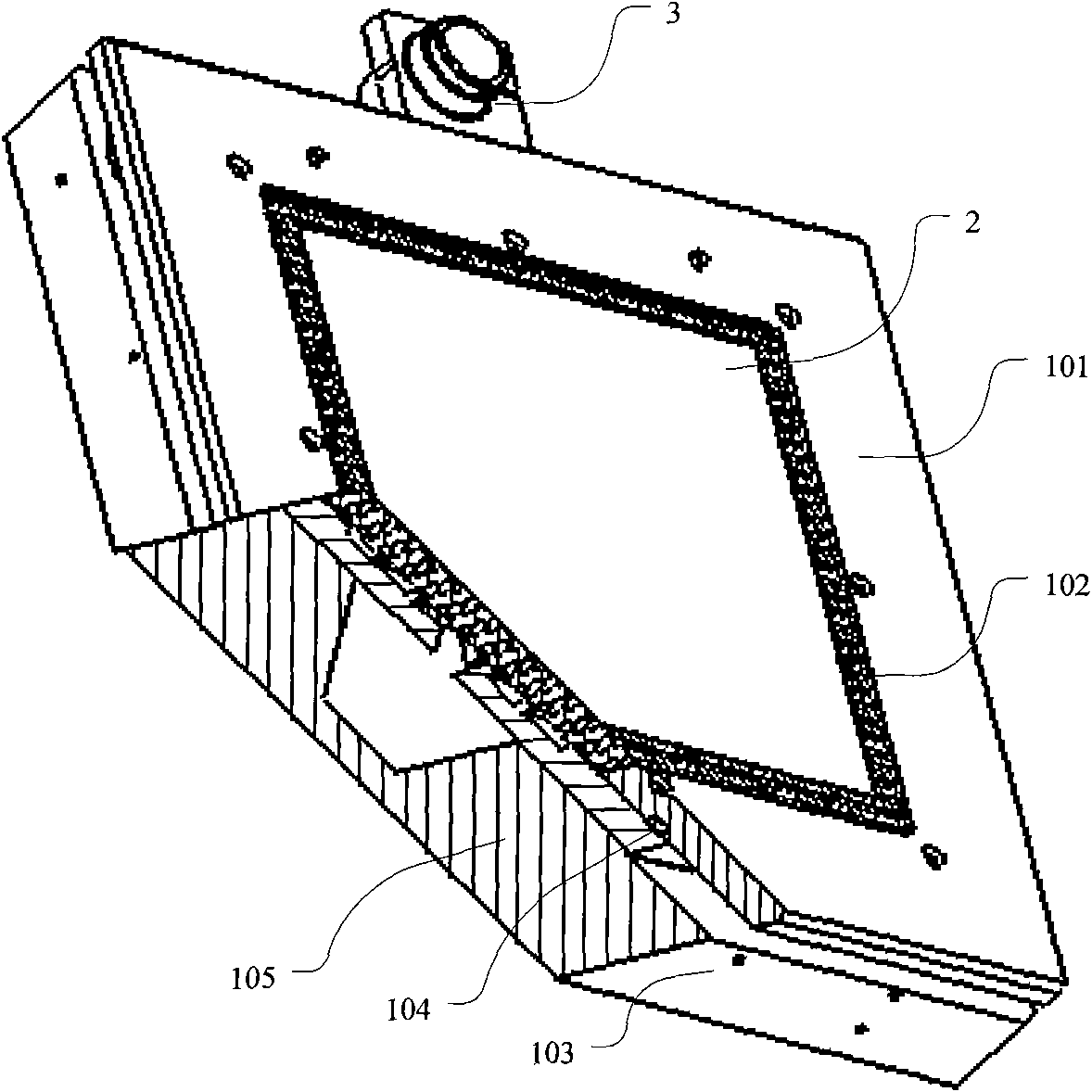

[0032] Vacuum suction wafer stage 1, such as figure 2 As shown, the PSD device 3 is attached thereon, and the adsorption and fixation of the calibration substrate 2 can be completed. The vacuum chamber is formed by the wafer stage base 103, the wafer stage base plate 105, the wafer stage frame 101, the honeycomb board 102 and the polyurethane round belt 104, and the vacuum chamber is connected with the vacuum cleaner through a spring hose; the calibration substrate 2 is placed on the honeycomb board 102. The small residue generated during the processing enters the vacuum cleaner through the core hole on the honeycomb panel 102 , the through hole of the wafer base 105 and the cavity of the wafer base 103 . The polyurethane round b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com