Combined functional rod-toothed crusher

A technology of roller crushers and functional teeth, which is applied in the field of crusher production and combined functional teeth roller crushers, can solve problems such as easy to produce stuffy cars, achieve the effects of saving coal, purifying the environment, and facilitating construction and renovation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The concrete technical scheme of the present invention will be further described below in conjunction with embodiment:

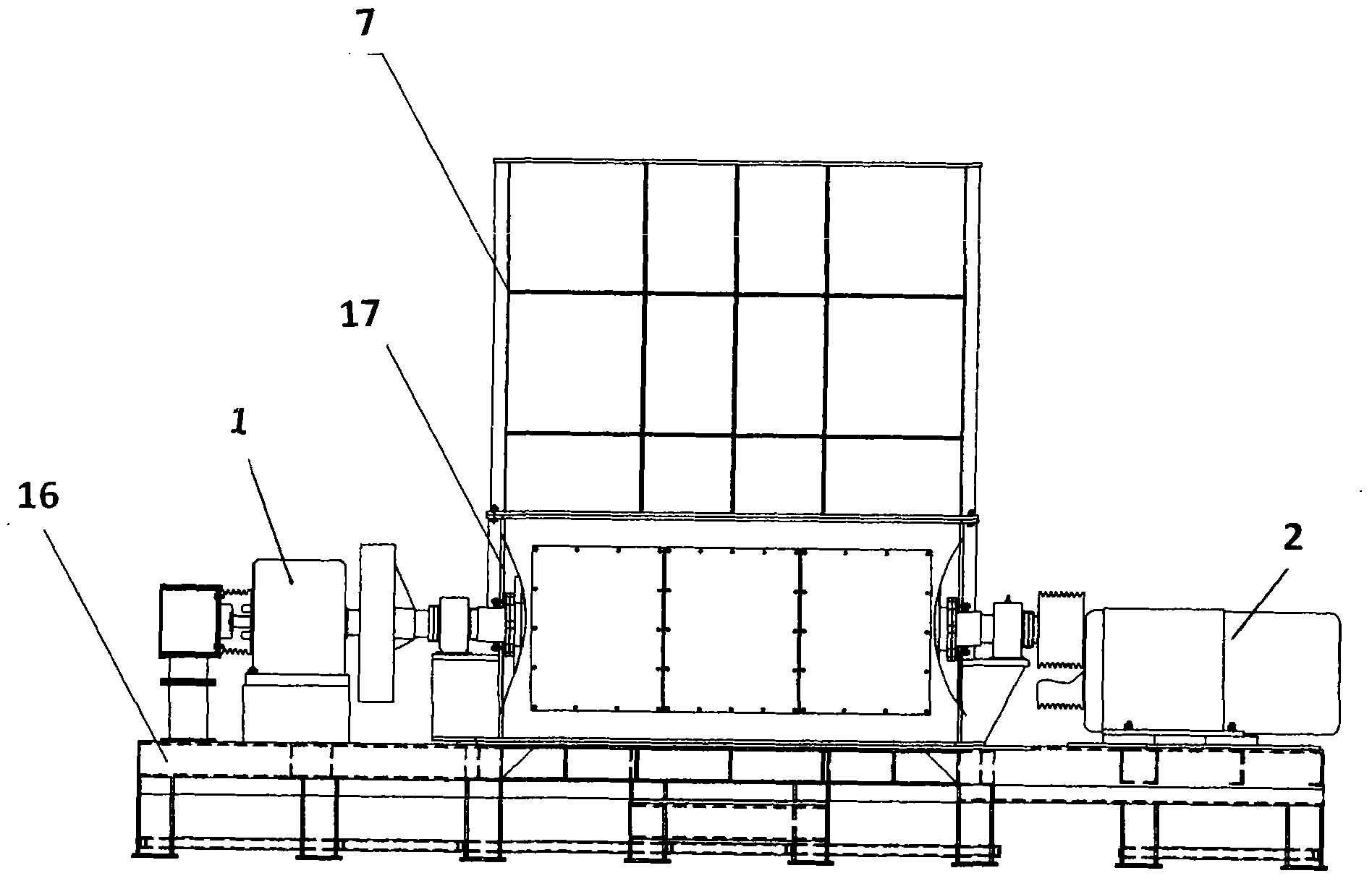

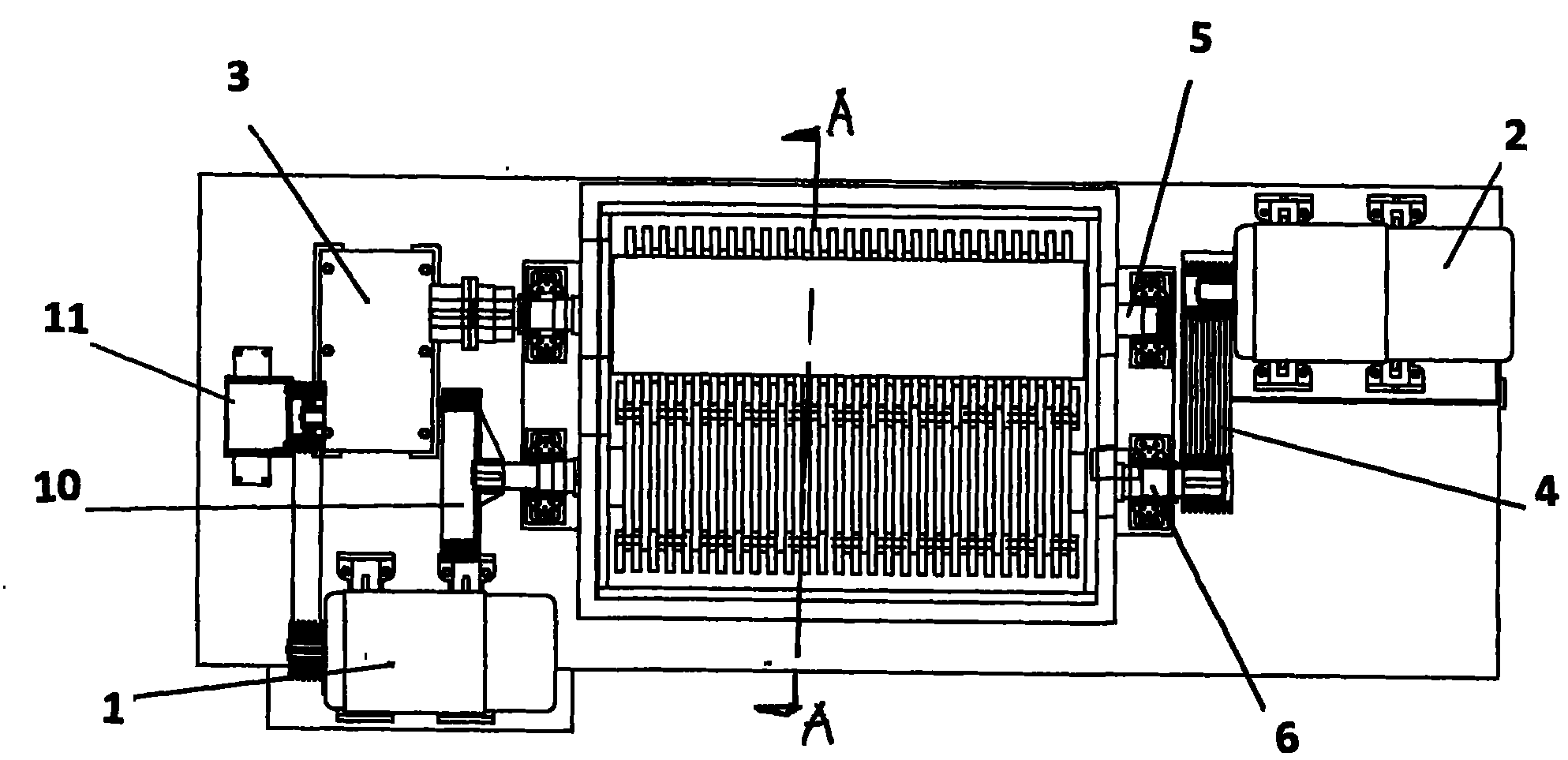

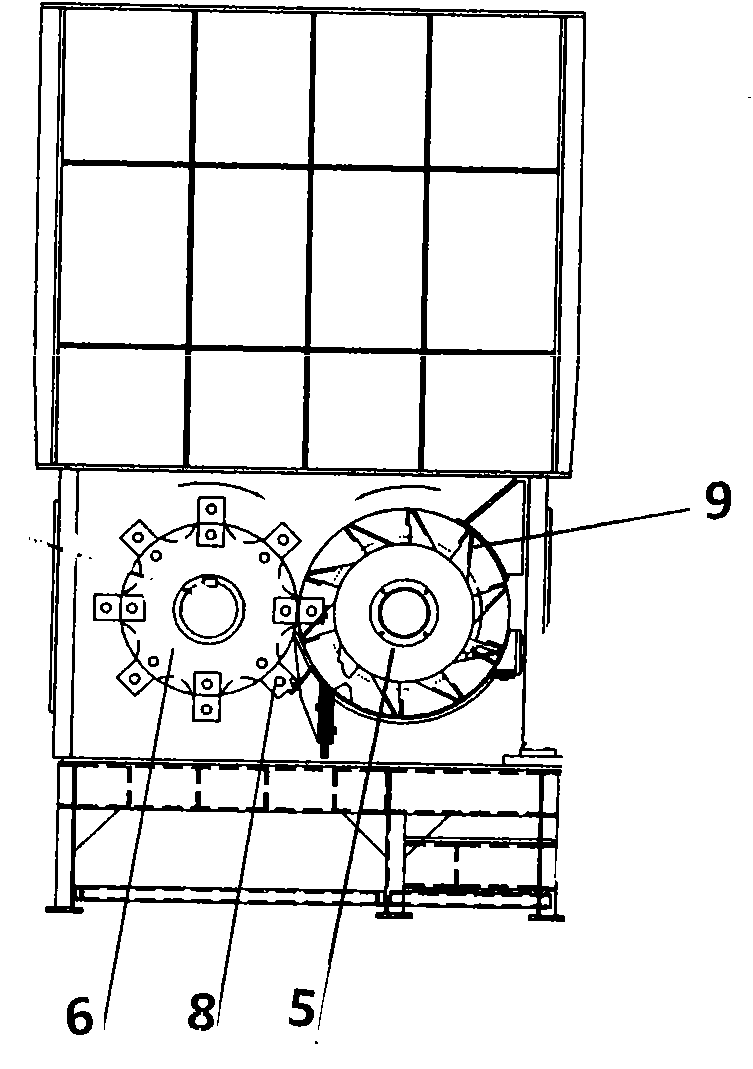

[0026] Such as Figure 1 ~ Figure 3 As shown, this combined function toothed roller crusher includes a hopper 7, a crushing system 17, a base 16 and an electrical control part. The crushing system 17 is mainly composed of a main drive motor 1, a reducer 3, and a low-speed toothed roller rotor 5 , a secondary motor 2, and a high-speed toothed roller rotor 6, wherein the low-speed toothed roller rotor 5 and the high-speed toothed roller rotor 6 are arranged side by side on the side of the discharge port of the feeding hopper 7, and the high-speed toothed roller rotor 6 is provided with multiple sets of rotating Flying knife 8, the low-speed toothed roller rotor 5 is provided with multi-edged knife teeth 9 with zigzag grooves on the rear angle surface arranged in a linear arrangement, and the low-speed toothed roller rotor 5 is connected to the main driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com