Organic glass ion exchange column without flange

An ion-exchange column and plexiglass technology, applied in the field of ion-exchange columns, can solve the problems of no flange, plexiglass ion-exchange column sealing failure, damage, etc., to reduce the possibility of damage, reduce wall thickness, and improve column intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

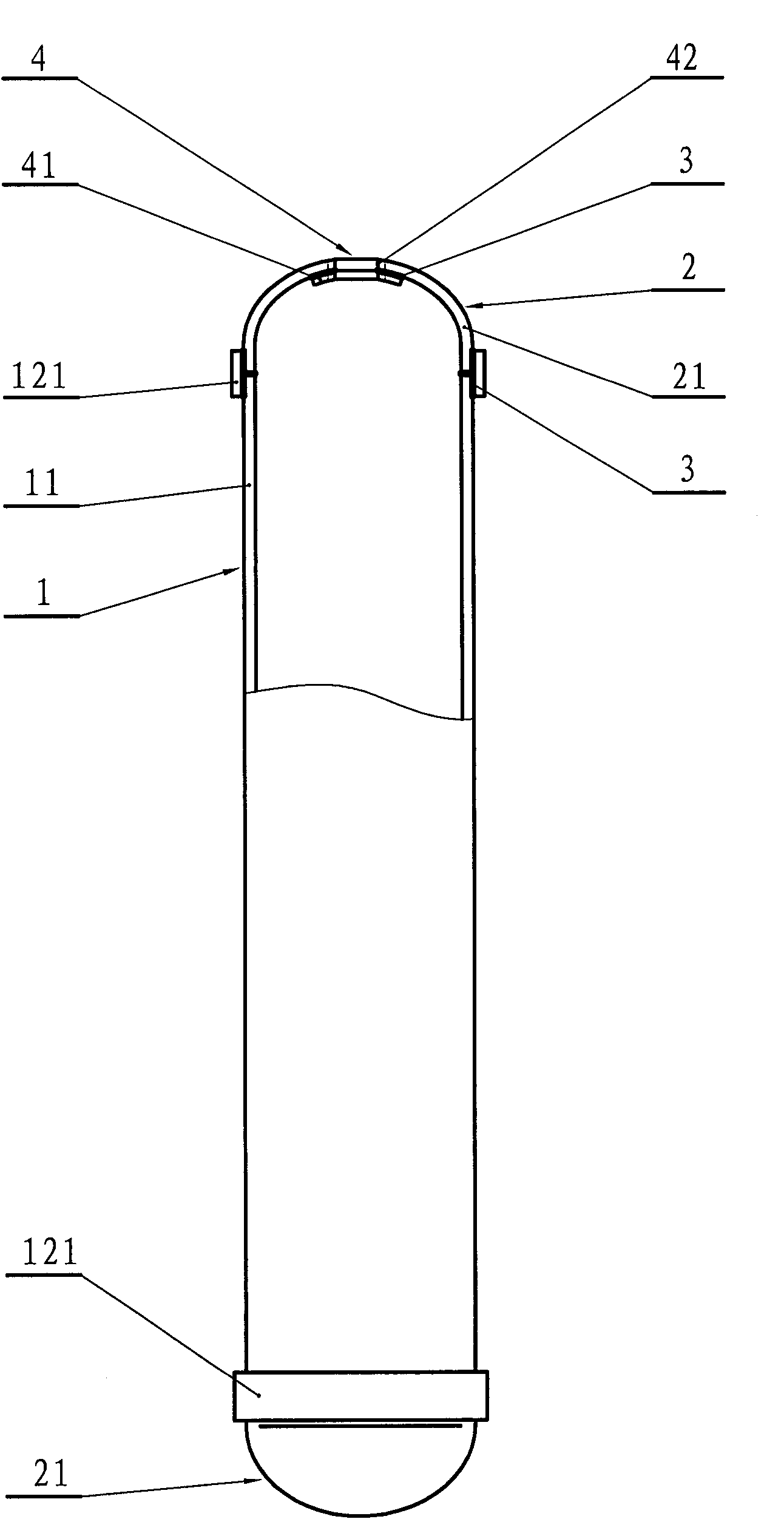

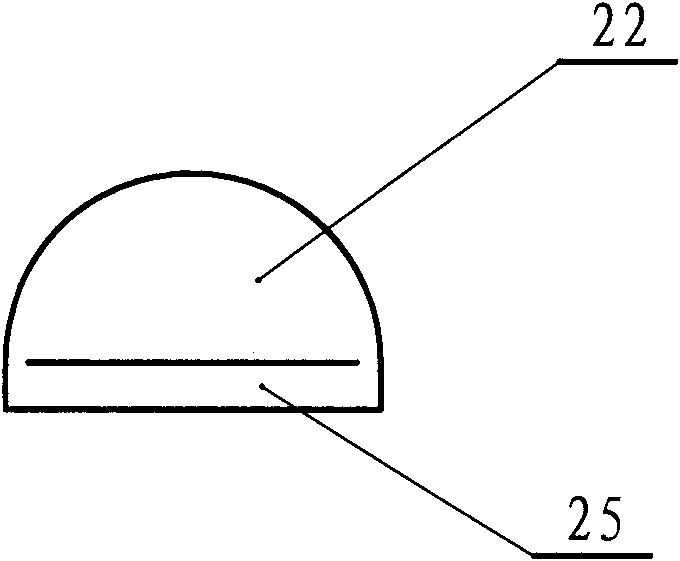

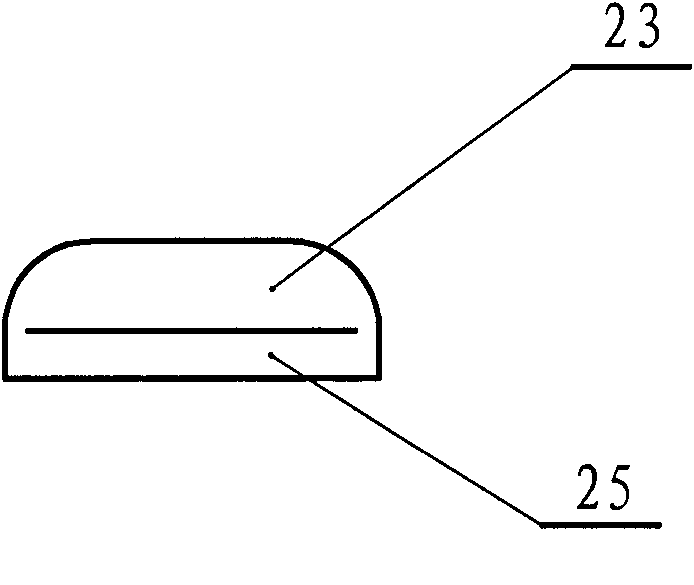

[0034] The organic glass ion exchange column without flange of the present invention has a structure as attached figure 1 As shown, it includes a closed container formed by connecting a cylinder 1 made of plexiglass and a head 2 at both ends of the cylinder. The cylinder 1 is a cylindrical structure surrounded by a plate-shaped cylinder wall 11. The method that can ensure the strength of the cylinder 1 is processed. The head 2 adopts the head 21 with an oval symmetrical cross-section arch structure. The symmetrical cross-section of the head 21 is an ellipse that is divided along the long axis of the ellipse and rotates around the short axis of the ellipse. In the arched structure formed by 180 degrees, the length of the major axis of the ellipse is the same as the diameter of the corresponding part of the cylinder wall 11, as attached figure 1 shown. The cylinder 1 and the heads 2 at both ends of the cylinder 1 are bonded together with an adhesive 3 . Adhesive 3 should use o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com