Double-side vacuum large volume injection and process for detecting liquid leakage rapidly

A double-layer vacuum, large-capacity technology, used in the use of liquid/vacuum for liquid tightness measurement, medical container, packaging item types, etc. , to achieve the effect of reducing medical accidents, ensuring physical health, and reducing the leakage rate of bags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

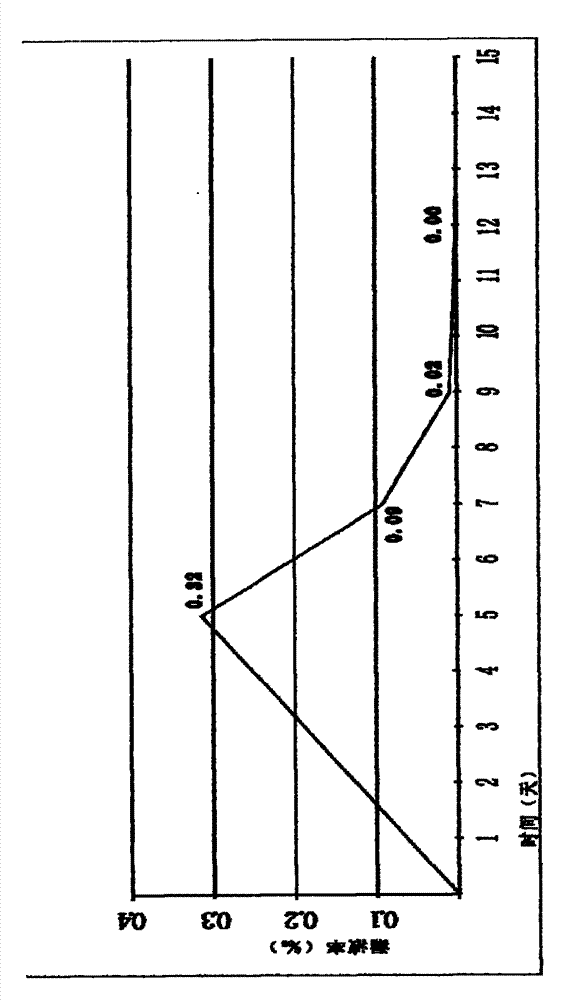

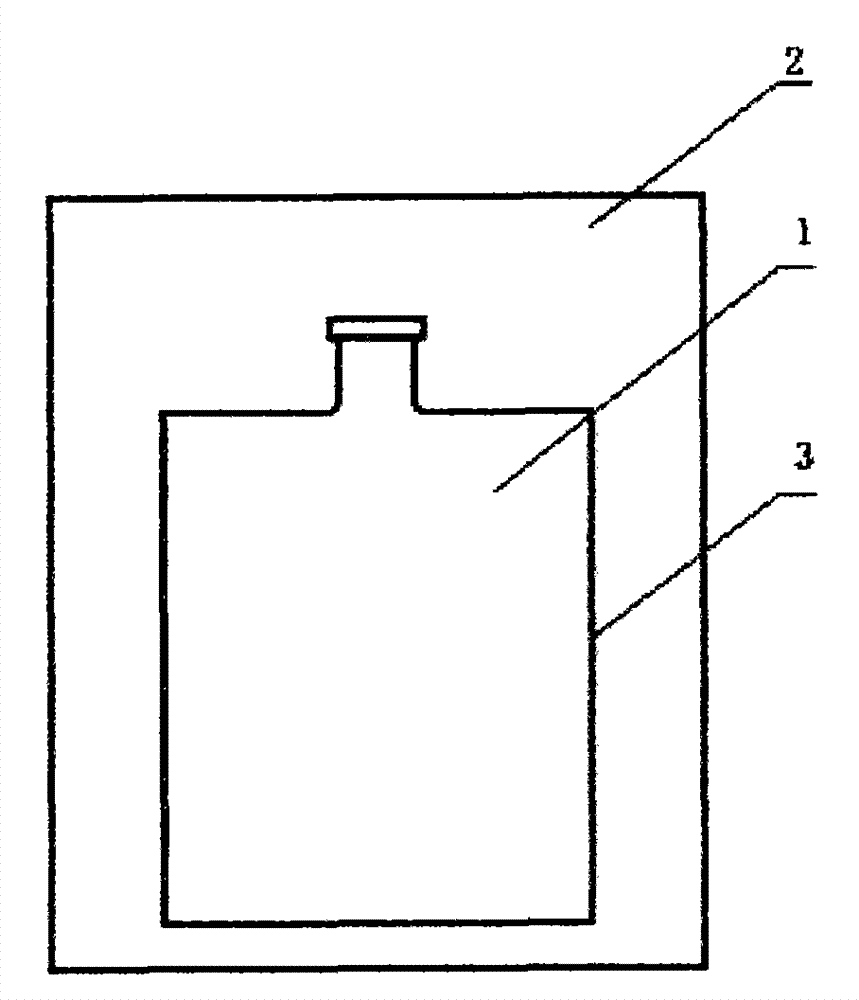

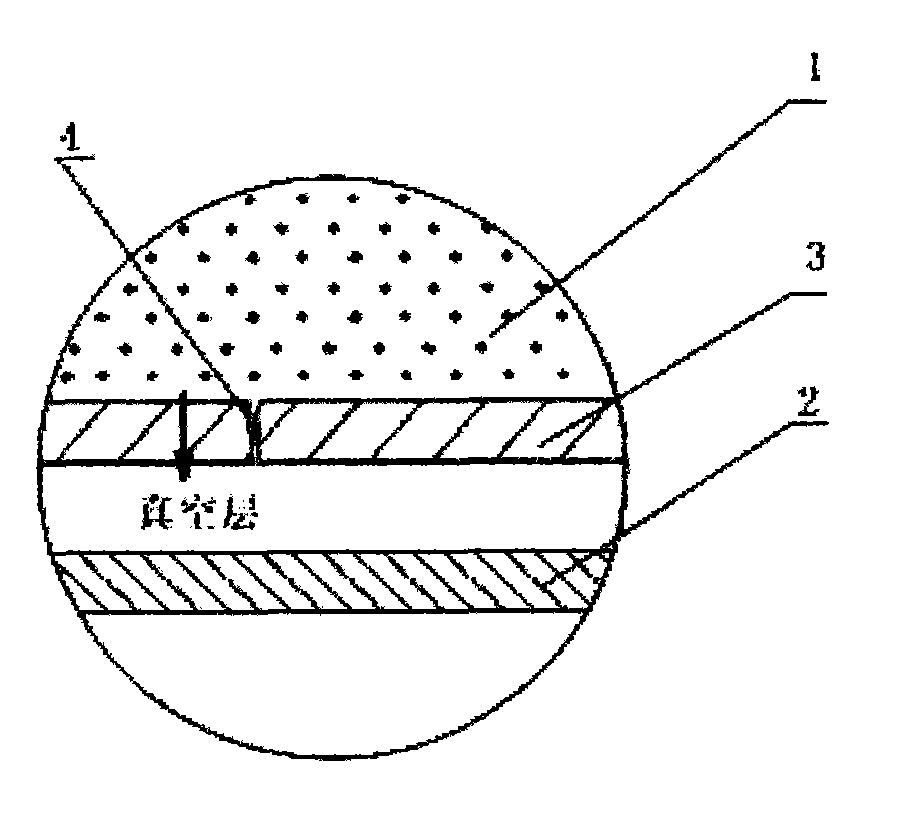

[0026] According to the present invention to produce large-capacity injections, the inner packaging is filled with pharmaceuticals first, and then the protective outer bag is placed on the outside. The protective outer bag is a transparent PP composite nylon film material, and a relative vacuum is drawn between the inner packaging and the protective outer bag. The degree is -0.05Pa to -0.1Pa. Then heat seal the protective outer bag, and remove the large-capacity injection with obvious leakage, and store it in the temporary warehouse; within 13 to 15 days of storage in the temporary warehouse, turn out the packaged large-volume injection again , put the product under the light of 2000 Lux for liquid leakage inspection, among them, the large-capacity injection that has produced water droplets or mist between the protective outer bag and the inner packaging is a large-capacity injection that has leaked out.

[0027] Among the large-capacity injections, including glass bottle inf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com