Light emitting device, display device and manufacturing method of the light emitting device

A technology of a light-emitting device and a manufacturing method, which can be applied to the parts of the lighting device, the cooling/heating device of the lighting device, the lighting device, etc., can solve the problem of heating of the light-emitting element, and achieve the effect of suppressing the fluctuation of the light quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

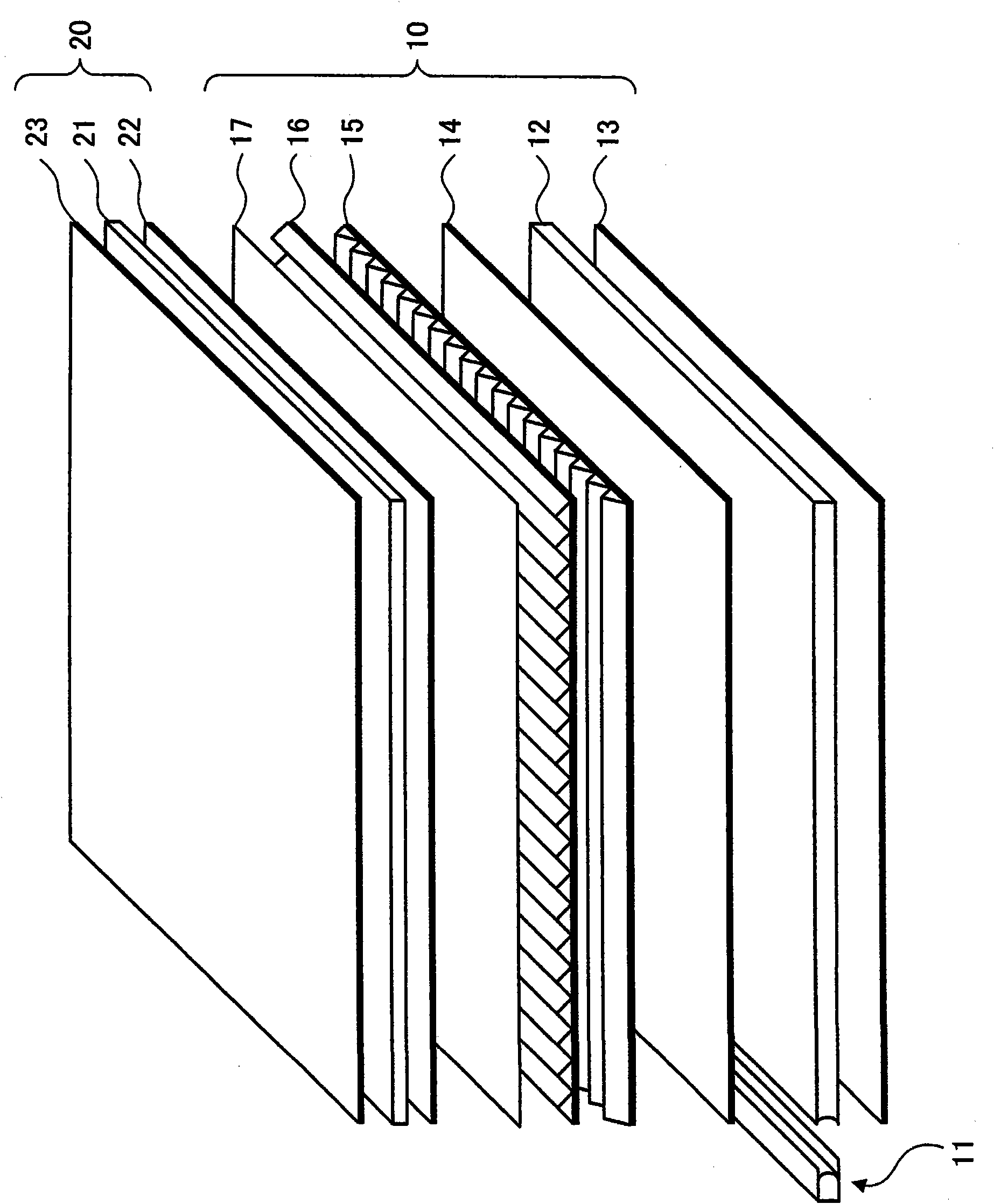

[0031] figure 1 It is a diagram showing the overall configuration of a liquid crystal display device to which this embodiment is applied. The liquid crystal display device includes a liquid crystal display module 20, and a figure 1 The middle is the backlight device 10 on the lower side). It should be noted that, in this embodiment, a so-called edge-light type backlight unit 10 is employed.

[0032] The backlight unit 10 includes a light source unit 11 , a light guide plate 12 , a reflection sheet 13 , a diffusion sheet 14 , prism sheets 15 and 16 , and a brightness improvement film 17 .

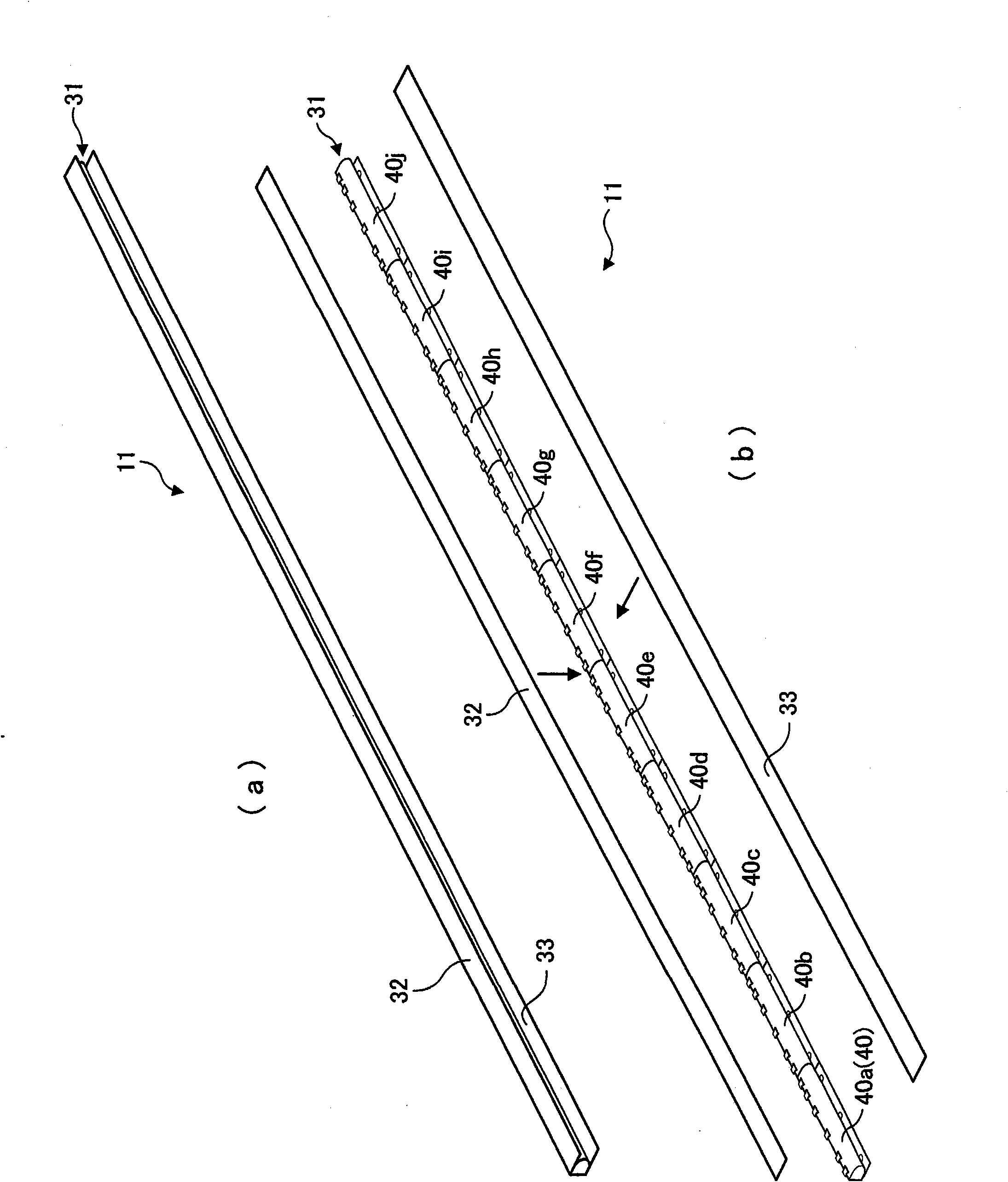

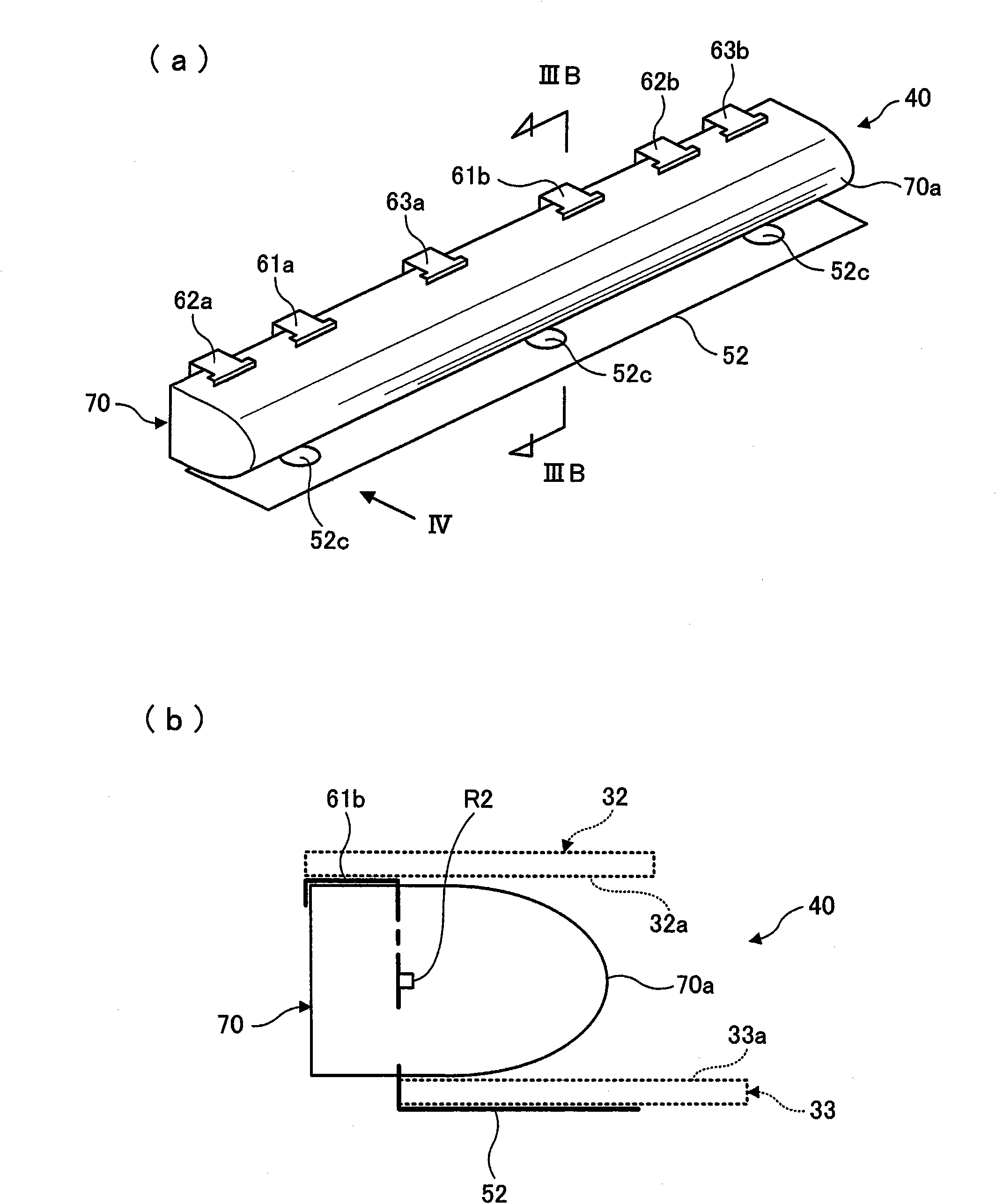

[0033] The light source device 11 is arranged to face the side of one side (long side) of the light guide plate 12 . In the present embodiment, the light source device 11 is configured by arranging a plurality of LEDs that emit light of each color of red (R), green (G), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com