Pump rotor for a canned motor pump

A technology of shielding pumps and rotors, which is applied to the components, pumps, and pump devices of pumping devices for elastic fluids, can solve problems such as being difficult to minimize, and achieve the effects of minimizing unbalance, reducing unbalance, and reliable sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

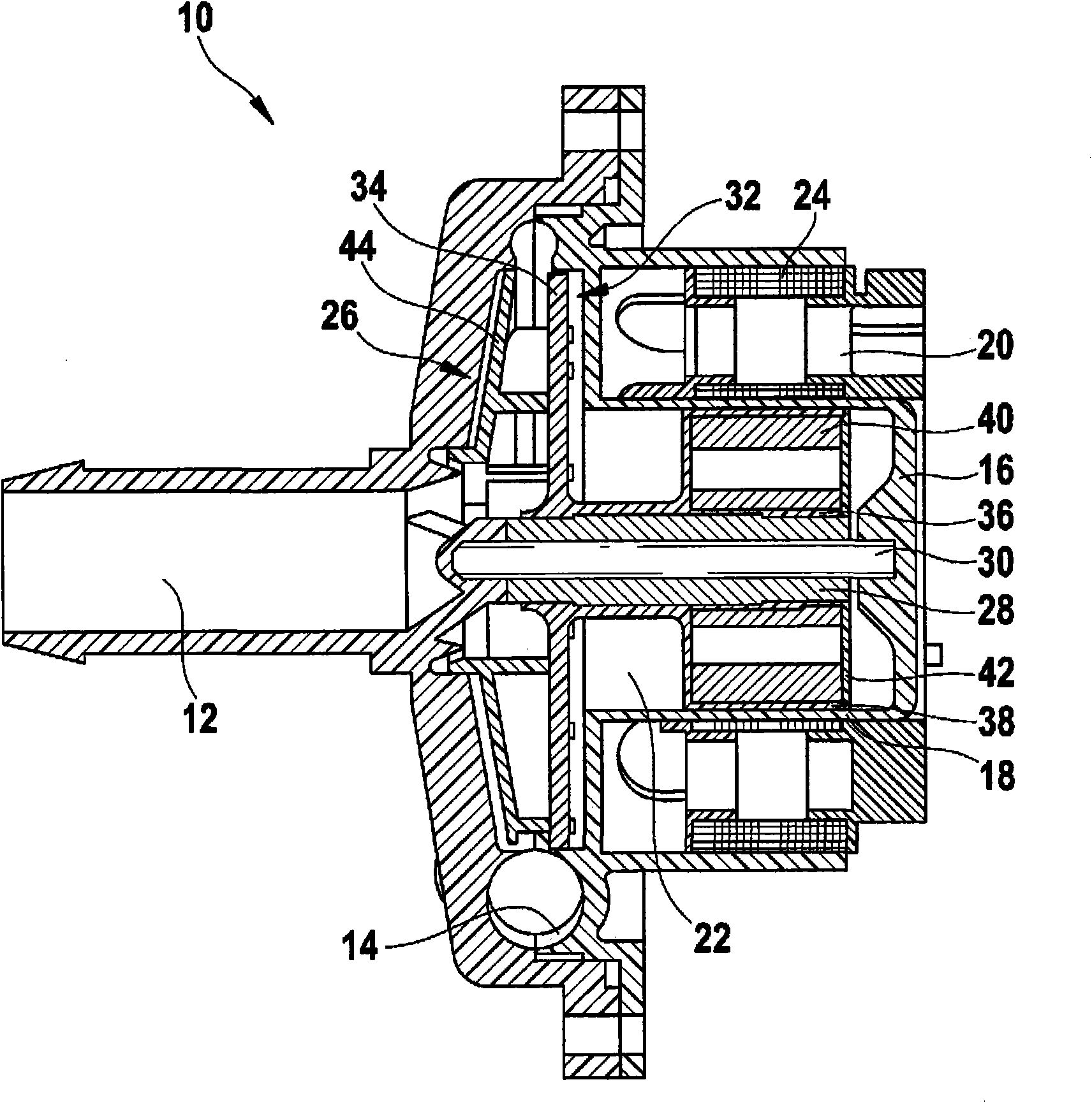

[0025] exist Figures 1 to 3b A first embodiment of the invention is shown in . Depend on figure 1 It can be seen that the canned pump 10 comprises inflow and outflow channels 12 , 14 for the liquid to be pumped, for example the coolant in the cooling circuit of the internal combustion engine, and that the engine housing 16 is designed in such a way that it is divided into stems by slots 18 . Chamber 20 and wet chamber 22, which are respectively sealed relative to each other.

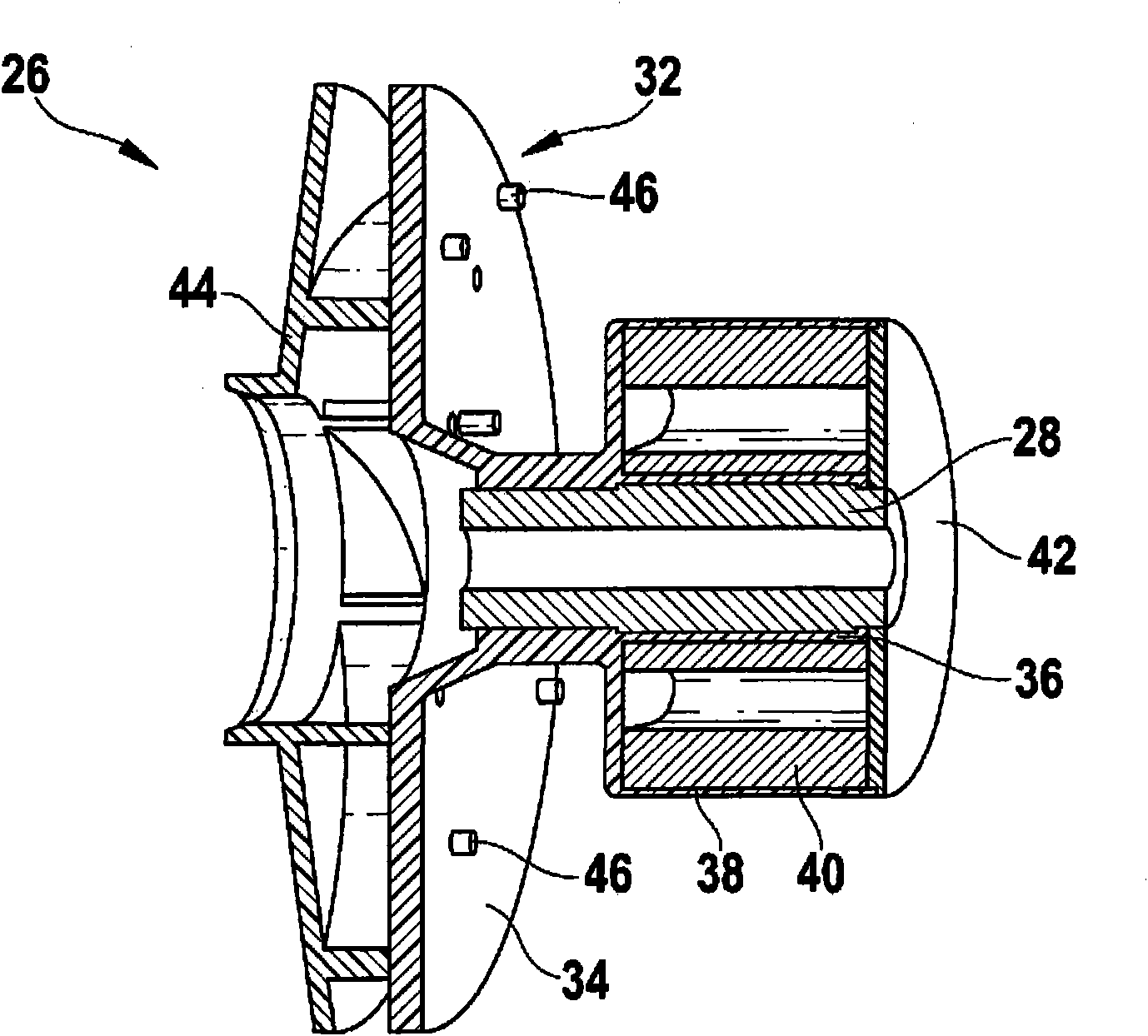

[0026] Within the dry chamber 20 are located a stator 24 and control electronics for driving the pump's electric motor. In the wet chamber 22 , the pump rotor 26 is rotatably supported by means of a bearing bush 28 on a shaft 30 which is fixedly mounted in the motor housing 16 .

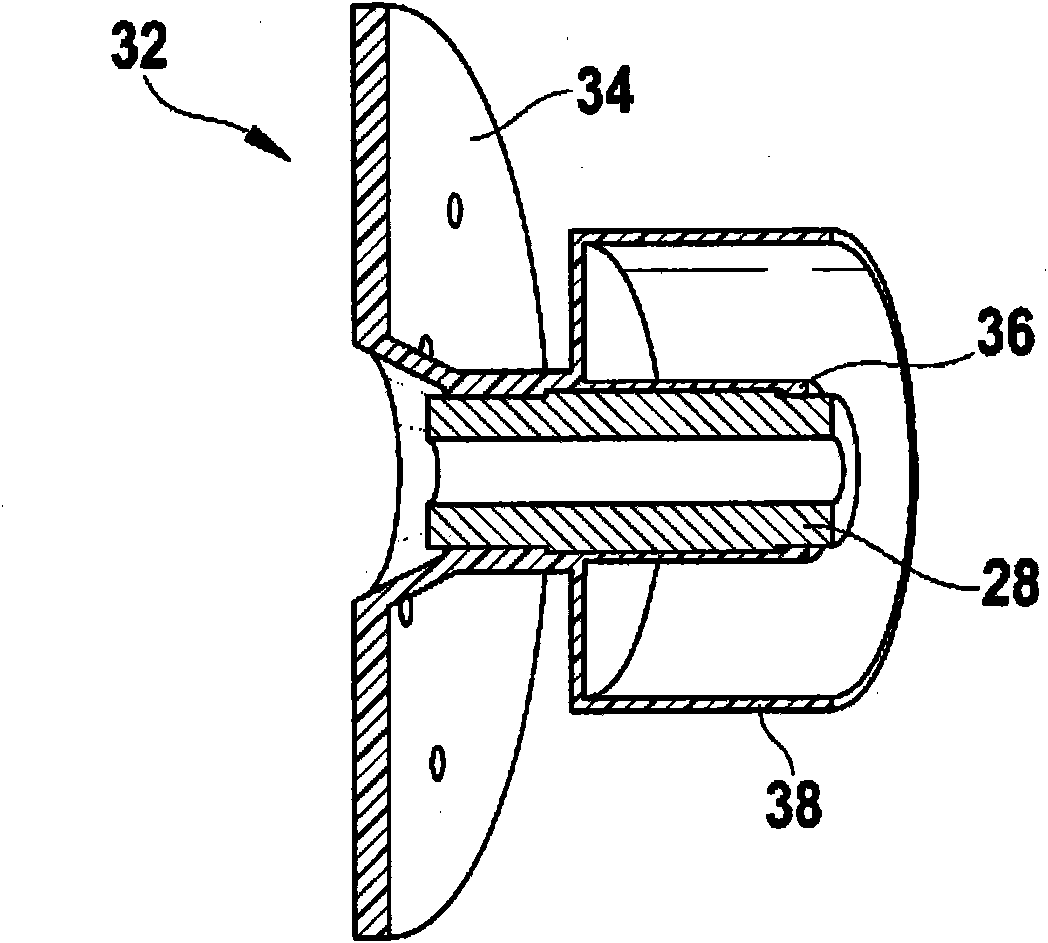

[0027] The pump rotor 26 includes a one-piece base body 32 having an impeller base plate 34 , a rotor receiving bushing 36 and a receiving sleeve 38 for receiving the rotor unit 40 . The open side of the receiving sleeve 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com