Flat-angle chip aslant sticking type back-off packaged electronic tag

A technology of electronic tags and chips, which is applied in the direction of circuits, seals, electrical components, etc., can solve the problems of diagonal antenna loops, circuit short circuits, narrow use range, etc., to improve packaging fault tolerance, reduce research and development costs, and work performance reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

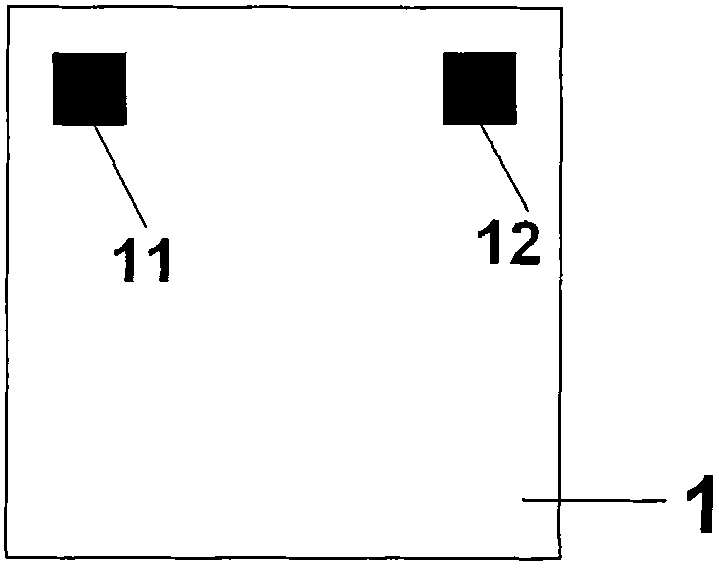

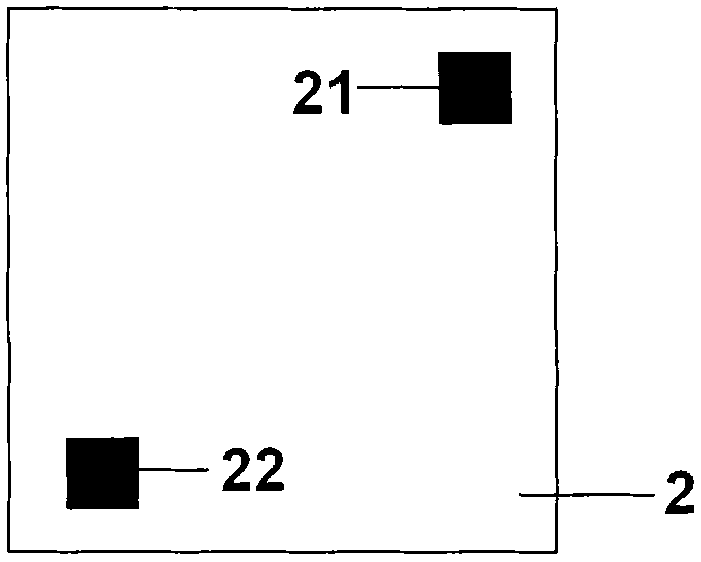

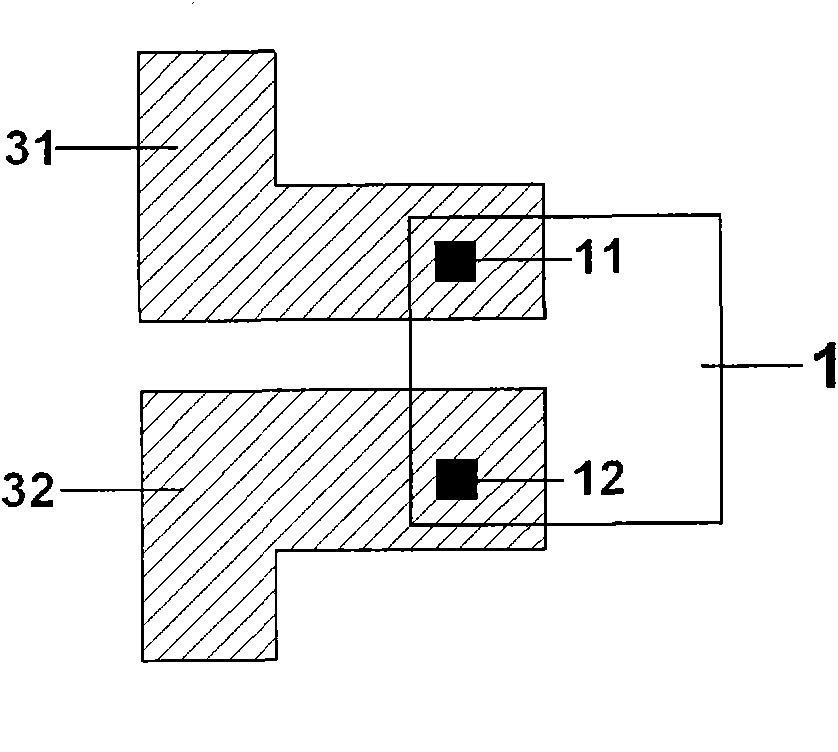

[0036] see Figure 6 , an electronic label with a flat-angle chip obliquely attached to an upside-down package, including a flat-angle chip 1 and a diagonal antenna, one side of the flat-angle chip 1 is provided with two binding points 11 and 12 at intervals, and the flat-angle chip 1 is obliquely attached to the On the pins 41 and 42 of the diagonal antenna, the two binding points 11 and 12 of the flat-angle chip 1 are respectively connected to the two pins 41 and 42 of the diagonal antenna.

[0037] The diagonal antenna is arranged on the substrate 5, including an antenna coil 43, a riveting point 45 arranged at the first and last ends of the antenna coil 43, and a bridge line 44 connecting the first and last riveting points 45 of the antenna coil 43, the antenna coil The innermost part of 43 is disconnected, and the two ends of the disconnection respectively lead to the pins 41 and 42 connected to the flat-angle chip 1. The flat-angle chip 1 is packaged on the two pins thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com