Built-in anti-seepage geomembrane damage monitoring method based on optical fiber temperature-measurement principle

A technology for optical fiber temperature measurement and geomembrane, which can be used in measurement devices, optical testing flaws/defects, thermometers, etc., and can solve problems such as research or achievement information that has not yet been retrieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] (1) Manufacture of fiber optic geomembrane

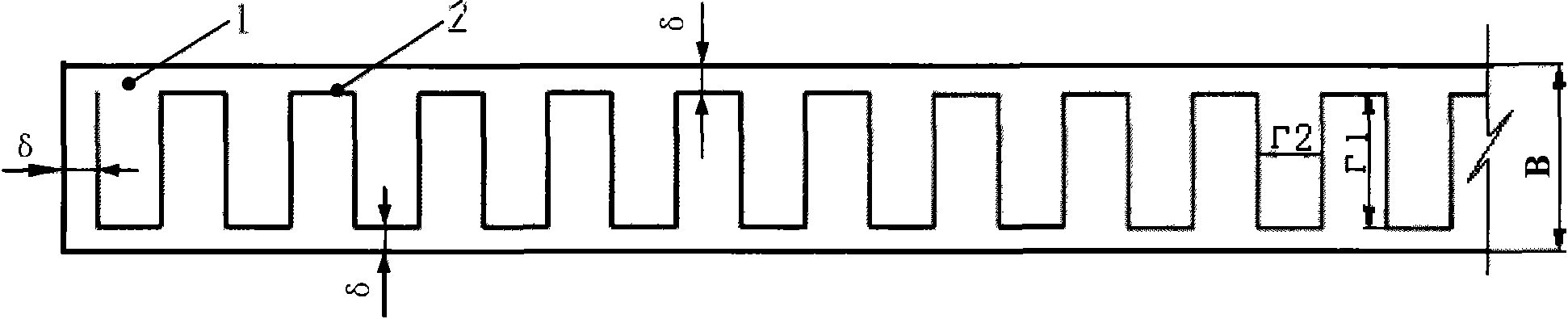

[0038] see figure 1 , in the production process of the traditional geomembrane 1, the optical fiber 2 is arranged in a serpentine manner, thereby obtaining an "optical fiber geomembrane". Let the width of the geomembrane be B, and leave δ (recommended 0.25m) at the edge of the geomembrane as the area without overlapping welding (bonding) of optical fibers, then the single length of the optical fiber Γ 1 = B-2δ; the optical fiber is sensitive to the temperature change within 0.5m on both sides, so the distance between the temperature measuring optical fibers Γ 2 ≤1m (0.6m recommended).

[0039] (2) laying optical fiber geomembrane

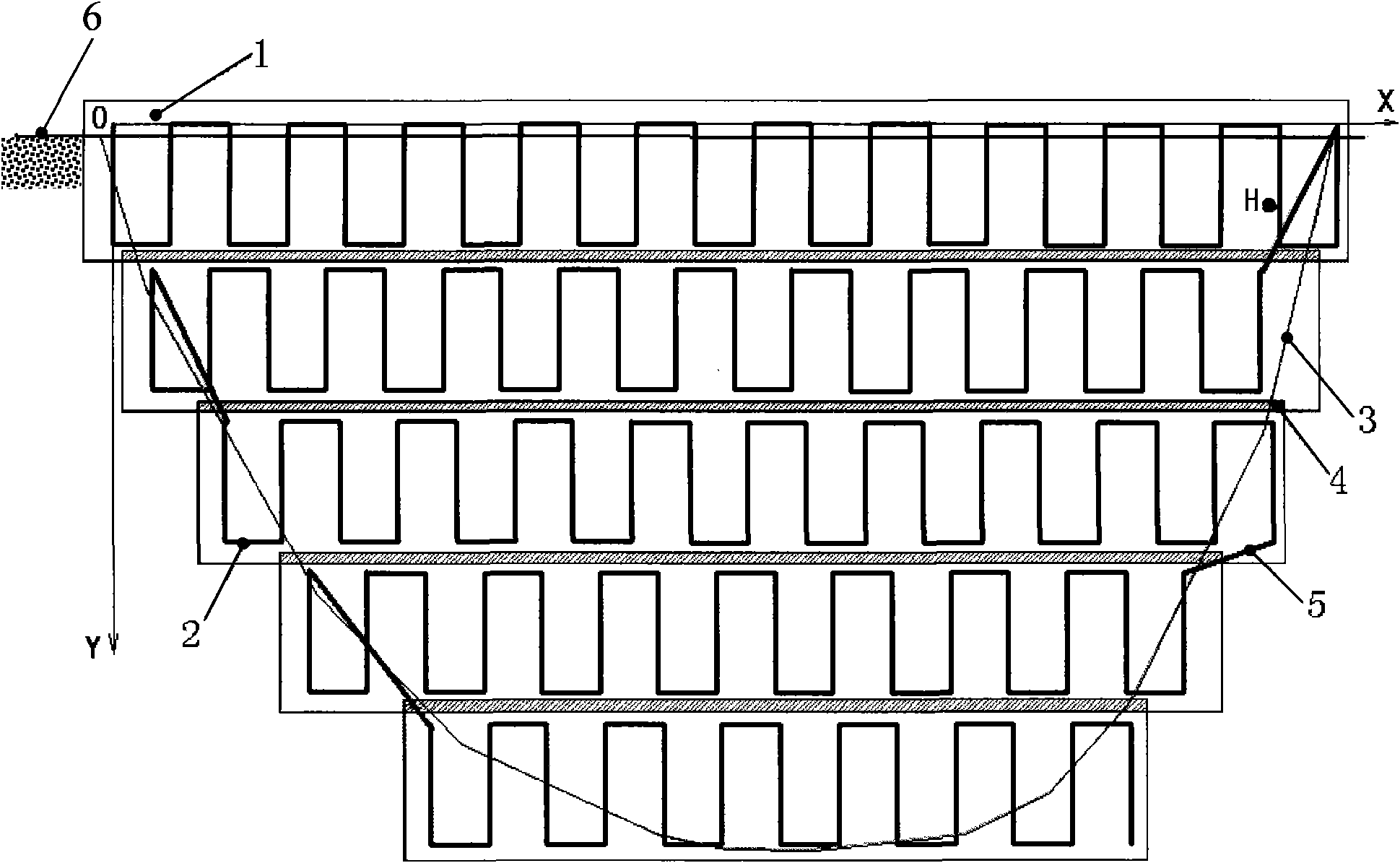

[0040] see figure 2 , in the construction process of the anti-seepage project, the above-mentioned optical fiber geomembrane 1 is used as the anti-seepage material, and the construction is carried out according to the current specifications. In order to avoid too many optical fiber joints and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com