Combination of fan cover assembly and extinguishing switch

A technology of flameout switch and fan cover, which is applied in the direction of engine control, machine/engine, mechanical equipment, etc. It can solve the problems of easy damage to the appearance of fan cover components, unreliable installation of flameout switch, and difficult to accurately control the interference, so as to achieve the goal of dismantling The effect of easy installation, simple structure, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

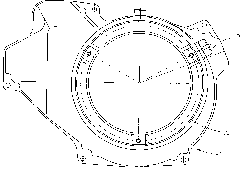

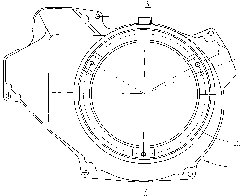

[0019] Such as Figure 1 to Figure 8 As shown, the present invention is made up of fan cover assembly 1, flameout switch 2, screw 3 and nut 4, and the shape and structure of fan cover assembly 1 adopts prior art, does not repeat them here. A circular casing 1a is integrally formed on the fan casing assembly 1, and the casing 1a is as figure 1 , 2 There is a circular positioning hole 1b for inserting the flameout switch in the upper right part of the circle shown. The positioning hole 1b is a light hole, and the wall of the positioning hole 1b extends toward the center to form 2 to 4 limiting protrusions 1c evenly distributed on the circumference. In this embodiment, the number of limiting protrusions 1c is preferably There are 3 pieces, and each limiting tab 1c is rectangular, or arc-shaped or other suitable shapes. An assembly hole 1d is also opened on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com