Maintainable tunnel drainage system

A tunnel drainage and tunnel technology, applied in drainage, safety devices, mining equipment, etc., can solve problems affecting the normal use of tunnels, drainage system blockage, sedimentation, etc., to achieve the effect of maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

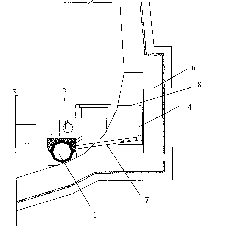

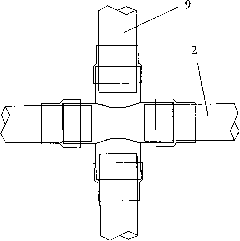

[0014] Such as Figure 1-Figure 3 As shown, the maintainable tunnel drainage system provided by the present invention includes two longitudinal drainage ditches 1, a plurality of horizontal and vertical drainage blind pipes 2, 9, a plurality of annular blind pipes 3, a plurality of inspection wells 4 and two side Ditch 5; two longitudinal drainage ditches 1 are respectively arranged inside the molded concrete layer 6 on both sides of the tunnel bottom along the longitudinal direction of the tunnel, and are connected to the water collection pump station; multiple horizontal and vertical drainage blind pipes 2 and 9 are criss-crossed It is connected between two longitudinal drainage ditches 1, and a plurality of water collection holes are formed on the upper peripheral surface; a plurality of circumferential blind pipes 3 are arranged on the molded concrete layer 6 of the vault along the circumferential direction of the tunnel at intervals. Among them, a plurality of water colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com